Related Blogs

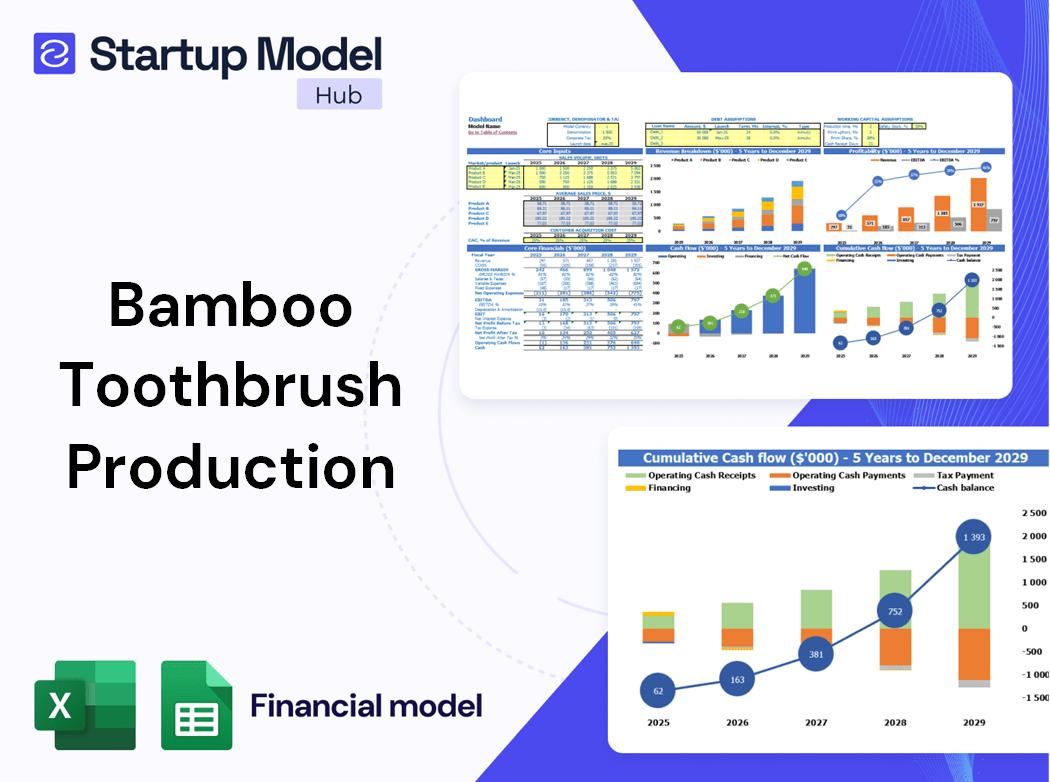

Are you considering diving into the eco-friendly market with a bamboo toothbrush production business? Understanding the top nine startup costs is essential for your success. From sourcing bamboo raw materials to initial inventory production, each expense can shape your financial strategy. Ready to explore the details? Discover a comprehensive business plan that can guide you through this journey at this link.

How Much Does It Cost To Start A Bamboo Toothbrush Production Business?

Starting a bamboo toothbrush production business, such as EcoBrush Co., involves several initial investments that can vary significantly based on the scale of operations and the chosen business model. On average, the startup costs for a bamboo toothbrush business can range from $50,000 to $150,000. This cost breakdown includes various essential components that contribute to the overall expenses:

- Bamboo Raw Materials: The cost of sourcing high-quality bamboo can range from $5,000 to $15,000 depending on the volume needed and supplier agreements.

- Manufacturing Equipment: Investing in bamboo toothbrush production equipment is crucial. Initial equipment costs can vary, but expect to spend between $20,000 and $50,000.

- Packaging Solutions: Eco-friendly packaging is vital for branding. Budget approximately $3,000 to $10,000 for sustainable packaging materials.

- Design and Prototyping Costs: Designing unique toothbrushes can cost around $2,000 to $8,000, depending on the complexity of the designs.

- Regulatory Compliance and Certifications: Ensuring your products meet health and safety standards might incur costs of $1,000 to $5,000.

- Marketing and Branding Initial Expenses: A solid marketing strategy is essential, with initial costs between $5,000 and $15,000 for branding, advertising, and promotional materials.

- Website Development and E-commerce Setup: An online presence is crucial; expect to invest around $3,000 to $10,000 for a functional website.

- Initial Inventory Production: Producing the first batch of toothbrushes may cost $10,000 to $30,000, depending on the quantity.

- Office and Warehouse Space Setup: Renting or leasing space can vary widely, with initial costs generally ranging from $5,000 to $20,000 for deposits and setup.

When planning for bamboo toothbrush manufacturing expenses, it's essential to consider both fixed and variable costs to ensure comprehensive financial planning. To navigate these costs effectively, entrepreneurs might explore various funding options, including grants, loans, or crowdfunding.

Tips for Cost Management

- Negotiate with suppliers to lower bamboo raw material costs.

- Consider leasing manufacturing equipment to reduce initial investment bamboo toothbrush business costs.

- Utilize digital marketing strategies to minimize bamboo toothbrush marketing strategy expenses.

Ultimately, understanding the cost breakdown of bamboo toothbrush production is vital for establishing a sustainable and profitable business model in the eco-friendly personal care market.

Is It Possible To Start A Bamboo Toothbrush Production Business With Minimal Investment?

Starting a bamboo toothbrush production business can indeed be feasible with minimal investment, especially if you approach the venture strategically. Many aspiring entrepreneurs worry about bamboo toothbrush production costs, but there are several ways to streamline expenses while maintaining quality and sustainability.

One of the most significant financial advantages when starting a bamboo toothbrush business is the ability to reduce initial manufacturing expenses. You can begin with a small-scale operation, leveraging local bamboo sources and affordable labor. For instance, it’s possible to start with a budget of approximately $5,000 to $10,000 if you are willing to manage production operations from home or a shared workspace.

Here are some methods to keep your startup costs for a bamboo toothbrush business low:

Tips for Minimizing Initial Investment

- Consider using pre-owned or less expensive bamboo toothbrush production equipment to cut costs. New machinery can be quite expensive, but used equipment is often available at a fraction of the price.

- Collaborate with local artisans or small-scale manufacturers who have existing capabilities in bamboo handling and production, which could save you from significant setup costs.

- Start small with a limited product line to gauge market interest, allowing you to reinvest profits into growth rather than incurring heavy upfront expenses.

Additionally, focusing on an affordable bamboo toothbrush production model can open doors to securing funding. Many funding sources, including grants and loans, are specifically aimed at sustainable businesses. A well-prepared bamboo toothbrush business plan can attract potential investors by showcasing your commitment to environmentally friendly practices and market potential.

On average, the bamboo toothbrush manufacturing expenses can be minimized through careful sourcing of bamboo raw materials and efficient production processes. By establishing partnerships with bamboo suppliers, you can negotiate better prices and ensure a steady supply. The initial investment for raw materials is relatively modest, often under $1,000, depending on your production scale.

Moreover, online platforms can significantly reduce your website costs for a bamboo toothbrush business. Utilizing e-commerce tools and social media marketing reduces the need for extensive advertising budgets. Research shows that digital marketing can achieve a return on investment (ROI) of up to 300% for sustainable products. This means that with minimal upfront investment in advertising, you can reach your target audience effectively.

In conclusion, with thoughtful planning and resource management, it is entirely possible to launch a bamboo toothbrush production business without a heavy financial burden. For further insights on profitability and budget management in this industry, consider checking resources like this article.

Which Costs Can Be Reduced for a Bamboo Toothbrush Production Business?

Starting a bamboo toothbrush production business involves various expenses. However, there are strategic ways to reduce startup costs while maintaining quality and sustainability. By identifying key areas where costs can be minimized, businesses like EcoBrush Co. can optimize their initial investment and enhance profitability.

Here are some significant cost-saving opportunities:

- Bamboo Raw Material Costs: Sourcing bamboo from local suppliers can significantly reduce transportation costs and ensure freshness. Building relationships with multiple suppliers may also help negotiate better prices.

- Manufacturing Equipment Expenses: Consider purchasing second-hand or refurbished bamboo toothbrush production equipment. This can reduce initial capital outlay by up to 40% compared to new equipment.

- Packaging Costs for Bamboo Toothbrushes: Opt for eco-friendly packaging options that are cost-effective yet appealing to eco-conscious consumers. Switching to biodegradable materials can cut costs by approximately 20% while aligning with brand values.

- Design Costs for Bamboo Toothbrush Prototypes: Utilize 3D modeling software to design prototypes in-house, which may lower design costs by as much as 50% compared to outsourcing.

- Marketing Strategy: Leverage social media and influencer partnerships for low-cost marketing. Utilizing organic content can decrease initial marketing expenses significantly, allowing for broader reach with minimal investment.

- Website Costs for Bamboo Toothbrush Business: Consider using affordable e-commerce platforms with integrated templates. This can cut website development costs to $200-$500, rather than spending thousands on custom builds.

- Initial Inventory Production: Start with a limited production run based on market research. This approach minimizes the risk of overproduction and reduces initial inventory costs.

- Office and Warehouse Space Setup: Consider co-working spaces or shared warehouse facilities until the business begins to scale. This can reduce overhead by up to 30%.

Tips for Reducing Costs

- Regularly review supplier contracts to ensure competitive pricing on raw materials.

- Always seek bulk purchasing options where feasible.

- Network with other eco-friendly businesses for shared resources and reduced costs.

For a detailed understanding of the financial aspects of bamboo toothbrush production, take a look at this article on bamboo toothbrush production costs.

By being strategic about these recurring expenses, EcoBrush Co. can maintain a competitive edge in the growing sustainable product market while keeping their bamboo toothbrush manufacturing expenses manageable.

Examples of Startup Budgets for Bamboo Toothbrush Production Businesses

When launching a bamboo toothbrush production business, such as EcoBrush Co., it’s essential to construct a detailed budget. The startup costs can vary significantly based on scale, location, and specific business strategies. Here’s an illustrative breakdown of potential expenses involved in the initial investment for a bamboo toothbrush production business.

Bamboo Raw Materials

The cost of sourcing bamboo, the primary raw material, can range from $1,000 to $3,000 depending on the quantity and quality required. Sustainable sourcing is crucial for maintaining the eco-friendly image of your business.

Manufacturing Equipment

Investments in bamboo toothbrush production equipment can amount to approximately $10,000 to $25,000. This includes machinery for cutting, shaping, and finishing, as well as tools necessary for efficient manufacturing.

Packaging Solutions

Eco-friendly packaging solutions can account for about $500 to $1,500 in initial costs. Customized designs to appeal to conscious consumers may incur additional expenses.

Design and Prototyping Costs

Creating prototypes involves design costs that typically range from $2,000 to $4,000. Engaging a professional designer or utilizing CAD technology can enhance product appearance and functionality.

Regulatory Compliance and Certifications

Costs associated with ensuring compliance with health and safety regulations may vary, but budgeting around $1,000 to $3,000 for necessary certifications is advisable.

Marketing and Branding Initial Expenses

To effectively reach your target market, initial marketing expenses for branding and promotional materials can total approximately $2,000 to $5,000. This may include digital marketing, influencer partnerships, and sustainable marketing strategies.

Website Development and E-commerce Setup

A professional website is vital for credibility and sales, costing about $1,500 to $3,000 for development, including e-commerce capabilities.

Initial Inventory Production

Creating an initial inventory may cost around $4,000 to $10,000, depending on the expected sales volume and product variety.

Office and Warehouse Space Setup

Depending on location, setting up a workspace can range from $500 to $2,500. This includes rent, utilities, and basic office supplies.

Budgeting Tips for Bamboo Toothbrush Production

- Consider lease-to-own options for manufacturing equipment to reduce upfront costs.

- Utilize online platforms for cost-effective marketing strategies.

- Network with local suppliers for better deals on bamboo raw materials.

In total, the estimated startup costs for a bamboo toothbrush production business can range from $23,500 to $56,000, depending on various factors. For a more detailed analysis, refer to resources that provide insights into bamboo toothbrush production costs and profitability [here](https://financialmodeltemplates.com/blogs/profitability/bamboo-toothbrush-production).

How to Secure Enough Funding to Start a Bamboo Toothbrush Production Business?

Starting a bamboo toothbrush production business like EcoBrush Co. requires a well-thought-out financial strategy. The startup costs for a bamboo toothbrush business can significantly vary depending on several factors including location, scale of production, and marketing approach. Generally, you may need to secure an initial investment ranging from $20,000 to $50,000 to cover various costs associated with bamboo toothbrush production.

Here are some strategies to secure funding:

- **Self-funding:** This is one of the most straightforward options. Use personal savings or revenue from other ventures to start your business.

- **Crowdfunding:** Platforms like Kickstarter or Indiegogo can help you reach eco-conscious consumers and raise funds while simultaneously gauging interest in your product.

- **Small Business Loans:** Approach banks or credit unions and prepare a detailed bamboo toothbrush business plan highlighting your start-up costs and expected revenues.

- **Angel Investors:** Look for investors who are keen on funding sustainable initiatives. Present a solid financial projection to attract their interest.

- **Grants and Competitions:** Explore government grants aimed at promoting small businesses or sustainability initiatives. Participating in competitions may also yield funding opportunities.

To effectively manage your startup costs, it's crucial to have a clear cost breakdown of bamboo toothbrush production. Major areas requiring funding typically include:

- Bamboo raw material costs – approximately $3,000 to $5,000 for initial procurement.

- Manufacturing equipment expenses – estimated at $10,000 to $30,000, depending on the scale of production.

- Packaging costs for bamboo toothbrushes, often around $1,000 to $3,000.

Consider these tips for effective funding:

Tips for Securing Funding

- Prepare a detailed financial plan that outlines your expected bamboo toothbrush manufacturing expenses and projected revenue.

- Network within eco-friendly and sustainable business communities to gain insights and potential contacts for funding.

- Utilize social media and your website to create awareness and interest in your product, potentially attracting investors.

In addition, having a robust bamboo toothbrush marketing strategy can make your business more appealing to potential investors. Clear, realistic projections about market trends and environmental impact can enhance your credibility.

For deeper insights, check out [this detailed profitability guide](https://financialmodeltemplates.com/blogs/profitability/bamboo-toothbrush-production) that provides benchmarks and statistics relevant to bamboo toothbrush production. Understanding these metrics can significantly boost your chances of securing funding and establishing a successful business.

How to Use the Financial Plan for Your Bamboo Toothbrush Production Business?

Creating a comprehensive financial plan is essential for the success of your bamboo toothbrush production business, such as EcoBrush Co. A well-structured financial plan enables you to effectively manage startup costs, forecast revenues, and track expenses, ensuring that your business remains viable and competitive in the eco-friendly market.

One of the key components of your bamboo toothbrush business plan should be a detailed cost breakdown. This involves outlining various bamboo toothbrush production costs, such as:

- Bamboo raw material costs: The price of bamboo can range from $800 to $1,200 per ton, depending on quality and sourcing. Aim to negotiate favorable contracts with suppliers to minimize expenses.

- Manufacturing equipment expenses: Initial investments in bamboo toothbrush production equipment can vary, with costs typically ranging from $15,000 to $30,000 for basic machinery.

- Packaging costs for bamboo toothbrushes: Eco-friendly packaging solutions are crucial; budgeting around $2,000 to $5,000 for initial designs and materials is advisable.

- Design costs for bamboo toothbrush prototypes: Expect to invest between $1,500 to $3,000 for design and prototyping to ensure functional and aesthetically pleasing products.

Utilizing financial projections, such as break-even analysis, will help you understand how much revenue is required to cover your fixed and variable costs. For instance, if your total fixed costs are estimated at $50,000 annually, and your average revenue per toothbrush is $5, you would need to sell at least 10,000 units to break even.

Budgeting Tips for Bamboo Toothbrush Production

- Prioritize expenditures by focusing on essential items first, such as raw materials and equipment.

- Regularly review your financial plan to identify areas for cost reduction, particularly in manufacturing processes.

- Utilize financial modeling tools to assess different scenarios and optimize your startup funding strategies.

In addition to costs, consider your bamboo toothbrush marketing strategy. Allocating around 10-15% of your initial budget for marketing efforts can enhance brand visibility, driving customer engagement and ultimately leading to increased sales.

By efficiently tracking your bamboo toothbrush manufacturing expenses and adjusting your financial plan as needed, you can ensure sustainable growth and profitability. For more insights on profitability models specific to bamboo toothbrush production, explore resources like this article.

Lastly, always keep in mind the importance of regulatory compliance and certifications in the production of sustainable products. These costs, though potentially variable, should be included in your financial planning to avoid any unexpected financial burdens.

What Are The Expenses To Start A Bamboo Toothbrush Production Business?

Starting a bamboo toothbrush production business involves a variety of expenses that can significantly impact your initial investment. Understanding the key costs associated with this venture is crucial for forming a robust bamboo toothbrush business plan. Here’s a detailed breakdown of the primary expenses you can expect:

Bamboo Raw Materials

The cost of bamboo is a critical factor in your bamboo toothbrush production costs. Quality bamboo can range from $2 to $5 per kg, depending on sourcing and quality. On average, starting your production might require about 100-200 kg of bamboo, which can total approximately $200 to $1,000.

Manufacturing Equipment

The bamboo toothbrush manufacturing expenses are mainly driven by the machinery needed for production. Expect to invest around $10,000 to $50,000 for the necessary equipment, including cutting tools, polishing machines, and assembly lines.

Packaging Solutions

Effective branding and eco-friendly packaging are essential. Costs can range from $0.15 to $0.50 per package, with initial orders requiring a budget of about $1,000 to $5,000 for sustainable packaging solutions.

Design and Prototyping Costs

Investing in design can elevate your brand’s market appeal. Design and prototyping costs may total $2,000 to $10,000, depending on the complexity of the designs and the professionals you hire.

Regulatory Compliance and Certifications

Compliance with health and safety regulations is paramount. Obtaining necessary certifications could cost around $500 to $2,000, ensuring your products meet industry standards.

Marketing and Branding Initial Expenses

Setting aside budget for a bamboo toothbrush marketing strategy is essential. Initial marketing expenses can range from $1,000 to $5,000, covering advertisements, social media campaigns, and promotional events.

Website Development and E-commerce Setup

A well-designed website is vital for online sales. Development and e-commerce setup can cost approximately $2,000 to $10,000, depending on functionality and design.

Initial Inventory Production

Creating an initial stock of bamboo toothbrushes is necessary. The cost of production for an initial inventory could range from $5,000 to $15,000, depending on your production volume and the variety of products offered.

Office and Warehouse Space Setup

Deciding on a physical location also incurs costs. Renting office and warehouse space may require a monthly budget of $1,000 to $3,000, plus initial setup costs for utilities and furnishings.

Tips for Reducing Startup Costs

- Consider leasing equipment instead of buying it to lower initial costs.

- Source raw materials directly from local suppliers to reduce shipping expenses.

- Utilize social media and word-of-mouth for marketing to save on advertising costs.

In total, startup costs for a bamboo toothbrush production business can range from $20,000 to $100,000, depending on factors such as production scale and market entry strategies. For a comprehensive view of potential revenue and profitability, consult resources like this bamboo toothbrush production guide for detailed insights.

Bamboo Raw Materials

When diving into the bamboo toothbrush production business, one of the primary considerations is the cost associated with sourcing bamboo raw materials. These costs can significantly impact the overall bamboo toothbrush production costs and should be thoroughly analyzed in your bamboo toothbrush business plan.

Typically, the cost of raw bamboo can vary based on quality, sourcing location, and market demand. On average, the cost of high-quality bamboo can range from $0.50 to $1.50 per kilogram. For an initial production run, a startup might require anywhere between 100 to 300 kilograms of bamboo, amounting to a total initial investment in raw materials between $50 to $450.

Here’s a breakdown of factors affecting bamboo raw material costs:

- Quality of bamboo: Premium varieties may cost more.

- Geographic location of sourcing: Local sourcing can reduce shipping costs.

- Market fluctuations: Prices can vary seasonally based on supply and demand.

- Long-term contracts with suppliers: May secure better rates compared to spot purchases.

Tips for Cost-Effective Sourcing

- Consider partnering with local bamboo farmers to reduce transportation costs.

- Research bulk purchase options to negotiate better rates.

- Explore sustainable harvesting methods that can also lower overall costs.

Additionally, it's important to factor in the potential costs related to quality assurance and testing. Ensuring the bamboo used for the toothbrushes meets health and safety standards could involve further expenses, estimated at around $200 to $500 depending on the required certifications.

While bamboo is an eco-friendly material, its acquisition process can include hidden costs. The transportation and storage of large quantities, especially if you're aiming for a cost-effective bamboo toothbrush production model, should also be included in your planning.

| Raw Material | Cost Range (per kg) | Total for 300 kg |

|---|---|---|

| Bamboo (High-Quality) | $0.50 - $1.50 | $150 - $450 |

| Quality Assurance Testing | N/A | $200 - $500 |

In summary, understanding the bamboo raw material costs is essential to effectively managing the startup costs for your bamboo toothbrush business. Planning ahead can lead to a more manageable financial structure and greater profitability in the long run. For those interested in a deeper financial analysis, check out [this financial model for bamboo toothbrush production](https://financialmodeltemplates.com/products/bamboo-toothbrush-production-financial-model).

Manufacturing Equipment

When embarking on a bamboo toothbrush production business like EcoBrush Co., understanding the bamboo toothbrush manufacturing expenses is crucial. One of the most significant components of your startup costs bamboo toothbrush business will be the manufacturing equipment required to produce high-quality toothbrushes efficiently.

Here’s a breakdown of the essential manufacturing equipment you will need:

- Automatic Bamboo Cutting Machine: Costs can range from $5,000 to $15,000 depending on the size and capability.

- Bristle Injection Machine: Essential for inserting eco-friendly bristles into the bamboo handles, prices typically range from $10,000 to $25,000.

- Polishing and Rounding Machines: These machines ensure smooth and safe edges for the toothbrushes, averaging $3,000 to $10,000.

- Packaging Machine: Necessary for efficient packing, with costs ranging from $2,000 to $8,000.

- Quality Testing Equipment: Ensures that your products meet health and safety standards, often costing around $1,500 to $5,000.

It's essential to factor in additional costs associated with these machines, including shipping, taxes, and installation, which can add 10-30% to the initial manufacturing equipment expenses.

Tips for Reducing Manufacturing Equipment Costs

- Consider purchasing used or refurbished machines to minimize initial investment.

- Explore leasing options, which can help distribute costs over time.

- Invest in multipurpose machines that can perform several tasks, reducing the total number of machines needed.

Creating an effective bamboo toothbrush business plan should include a detailed budget for manufacturing equipment. For instance, if you plan to operate on a budget of $50,000, allocating approximately $30,000 to manufacturing equipment can significantly affect your production capabilities.

| Equipment | Estimated Cost | Notes |

|---|---|---|

| Automatic Bamboo Cutting Machine | $5,000 - $15,000 | Essential for initial production. |

| Bristle Injection Machine | $10,000 - $25,000 | Crucial for adding eco-friendly bristles. |

| Polishing and Rounding Machines | $3,000 - $10,000 | Ensures safety and quality. |

| Packaging Machine | $2,000 - $8,000 | Streamlines the packing process. |

| Quality Testing Equipment | $1,500 - $5,000 | Maintains health standards. |

Overall, a comprehensive understanding of bamboo toothbrush production costs will not only help in securing the necessary startup funding bamboo toothbrush but also position EcoBrush Co. to be competitive in a rapidly growing market. Utilizing resources wisely and planning effectively will pave the way for a successful launch and sustainable growth in the eco-friendly toothbrush sector.

Packaging Solutions

When considering the startup costs for a bamboo toothbrush production business, it's crucial to allocate a sufficient budget for packaging solutions. Effective packaging not only protects the product but also plays a significant role in brand identity and consumer appeal. As an eco-friendly product, the packaging should align with the sustainable values that your business, EcoBrush Co., promotes.

The packaging costs for bamboo toothbrushes can vary significantly based on various factors:

- Material Type: Selecting biodegradable or recyclable materials can increase packaging costs, but this aligns with the eco-friendly branding.

- Design Complexity: Custom designs, including printing, logos, and colors, may add to the overall costs.

- Quantity Ordered: Bulk ordering of packaging materials can reduce costs per unit, allowing for better savings in the long run.

According to industry benchmarks, packaging can account for approximately 15% to 25% of the total bamboo toothbrush production costs. For a production run of 10,000 units, if the average cost of packaging per unit is $0.50, the total packaging expense would amount to $5,000.

| Type of Packaging | Estimated Cost per Unit | Total Cost for 10,000 Units |

|---|---|---|

| Simple Biodegradable Box | $0.30 | $3,000 |

| Custom Printed Box | $0.50 | $5,000 |

| Recyclable Pouch | $0.20 | $2,000 |

Investing in sustainable packaging can enhance your marketing strategy and attract eco-conscious consumers. Packaging solutions should not merely focus on functionality but also communicate the brand's mission of sustainability. This approach can differentiate EcoBrush Co. in a competitive market.

Tips for Effective Packaging Solutions

- Research local suppliers that specialize in sustainable materials to reduce shipping costs and support local businesses.

- Invest in a professional graphic designer to create compelling packaging designs that convey your brand message.

- Consider innovative packaging solutions like compostable materials or refillable options to further engage eco-minded consumers.

As a part of the initial investment for your bamboo toothbrush business, planning the cost breakdown for sustainable packaging is essential. Allocating funds wisely in this area can lead to higher customer satisfaction and brand loyalty, ensuring that EcoBrush Co. stands out as a leader in the sustainable personal care industry.

By focusing on cost-effective bamboo toothbrush production, including affordable packaging solutions, you can achieve an optimal balance between sustainability and profitability. As your business scales, continuously assessing your packaging needs and materials can provide opportunities for further cost savings and innovation.

Design and Prototyping Costs

When embarking on a bamboo toothbrush production business, the costs associated with design and prototyping can significantly impact your startup costs bamboo toothbrush business. Establishing a recognizable and functional product is crucial, particularly in a market that values sustainability and innovative design.

The design and prototyping phase involves several key expenditures that should be meticulously accounted for in your bamboo toothbrush business plan. Here’s a detailed breakdown of typical costs:

| Cost Category | Estimated Cost (USD) | Description |

|---|---|---|

| Design Fees | $1,000 - $3,000 | Hiring a designer or a design firm to create aesthetically pleasing and ergonomic toothbrush designs. |

| Prototyping Materials | $500 - $1,500 | Costs incurred for materials to create initial prototypes for testing and feedback. |

| Testing and Feedback | $300 - $800 | Expenses related to user testing, surveys, and focus groups to refine the design. |

| Iteration Costs | $200 - $600 | Costs associated with revisions based on feedback from the initial prototypes. |

In total, expect to allocate approximately $2,000 to $6,900 for design and prototyping alone. This investment is essential to ensure that your bamboo toothbrush not only fulfills its functional requirements but also resonates with eco-conscious consumers.

For affordable bamboo toothbrush production, consider leveraging digital design tools and 3D printing for rapid prototyping. These methods can significantly lower costs compared to traditional prototyping approaches.

Tips for Reducing Design and Prototyping Costs

- Utilize freelance designers on platforms like Upwork or Fiverr to find cost-effective design solutions.

- Seek feedback from friends or family before investing in professional testing.

- Consider using software like CAD to create and modify designs digitally before moving to physical prototypes.

By strategically budgeting for design and prototyping costs, you can establish a winning product in the bamboo toothbrush manufacturing expenses landscape. Moreover, an effective prototype can serve as a vital tool in securing startup funding bamboo toothbrush through investors who appreciate thoughtful and innovative product development.

Ultimately, the design phase is not merely an additional expense; it's a fundamental investment in your brand's identity and market fit. Every dollar spent on creating a product that aligns with consumer expectations could lead to increased sales and brand loyalty in the eco-friendly market.

For further guidance on financial planning for your bamboo toothbrush startup and to explore detailed budgeting templates, check out the comprehensive resources available at this link.

Regulatory Compliance and Certifications

Starting a bamboo toothbrush production business, such as EcoBrush Co., involves navigating a landscape of regulatory compliance and obtaining necessary certifications. These steps are crucial for ensuring that your products meet safety and environmental standards, which can significantly impact your startup costs.

The following are key regulatory considerations and certifications that are generally required for bamboo toothbrush businesses:

- FDA Regulations: In the United States, your bamboo toothbrush must comply with the Food and Drug Administration (FDA) regulations if you intend to market it as a dental product. This could involve application fees ranging from $1,500 to $4,500.

- ISO Certifications: Obtaining International Organization for Standardization (ISO) certifications for quality management (ISO 9001) and environmental management (ISO 14001) can enhance your credibility. Each certification may cost between $10,000 to $30,000 depending on your facility size and location.

- CE Marking: If selling within the European Union, you'll need CE marking to indicate that your product complies with EU safety, health, and environmental protection directives. The cost for CE marking can be around $5,000 to $15,000 depending on different factors.

- Eco-Labels: Consider obtaining eco-certifications like the Forest Stewardship Council (FSC) or the Rainforest Alliance. The costs may vary from $1,000 to $5,000, but they significantly boost consumer trust.

These regulatory and certification costs can contribute significantly to your bamboo toothbrush production costs. According to industry estimates, approximately **20-30%** of your startup budget may go toward compliance and certification efforts.

Additionally, it is essential to ensure that your manufacturing processes adhere to local laws regarding labor and environmental impact. Non-compliance can lead to hefty fines and damage your brand's reputation. For instance, companies producing eco-friendly products are often scrutinized for their sustainability practices.

| Cost Type | Estimated Cost Range | Notes |

|---|---|---|

| FDA Regulations | $1,500 - $4,500 | Required for dental product approval in the U.S. |

| ISO Certifications | $10,000 - $30,000 | Enhances credibility and quality assurance. |

| CE Marking | $5,000 - $15,000 | Mandatory for sales in the EU market. |

| Eco-Labels | $1,000 - $5,000 | Boosts consumer trust in sustainability. |

Tips for Navigating Regulatory Compliance

- Engage with a consultant who specializes in product compliance to streamline your application processes.

- Budget for ongoing compliance costs; regulations may change, necessitating updates to your certifications.

- Stay informed on industry standards through relevant forums and trade associations to keep your business aligned with compliance requirements.

In summary, understanding the regulatory landscape and planning for compliance costs can help you manage your startup costs for your bamboo toothbrush business effectively. With efficient compliance strategies, you can focus on your marketing strategy to highlight the eco-friendly benefits of your product, positioning EcoBrush Co. as a leader in sustainable personal care. For a detailed business plan that includes financial modeling for your bamboo toothbrush production, visit this link.

Marketing and Branding Initial Expenses

In the competitive landscape of sustainable products, effective marketing and branding are crucial to the success of your bamboo toothbrush production business. EcoBrush Co. must allocate a significant portion of its startup costs to these areas to ensure that the brand resonates with eco-conscious consumers. The initial investment in marketing and branding can vary, but here’s a typical breakdown of expenses you should anticipate:

| Expense Type | Average Cost | Importance Level |

|---|---|---|

| Logo and Branding Design | $1,000 - $3,000 | High |

| Website Development | $2,000 - $5,000 | High |

| Social Media Marketing | $500 - $2,000/month | Medium |

| Content Marketing (Blog, SEO) | $300 - $1,500/month | Medium |

| Initial Advertising Spend (PPC, Social Ads) | $1,000 - $5,000 | High |

When budgeting for bamboo toothbrush production costs, it’s essential to approach marketing expenditures strategically. Here are key components to consider:

- Logo and Branding Design: Investing in a professional logo and cohesive branding materials sets the tone for your company and creates a strong first impression. Expect to budget between $1,000 and $3,000 for a quality design.

- Website Development: Your website is the digital face of EcoBrush Co. It should be visually appealing, user-friendly, and optimized for e-commerce, requiring an initial investment of around $2,000 to $5,000.

- Social Media Marketing: Engaging in platforms that resonate with your audience is vital. Consider a budget of $500 to $2,000 per month to maintain a strong presence on social media.

- Content Marketing: Regular blog posts and optimized content can enhance your site’s searchability and engage customers. Allocate approximately $300 to $1,500 monthly for effective content strategies.

- Initial Advertising Spend: To reach potential customers quickly, set aside a budget ranging from $1,000 to $5,000 for pay-per-click and social media advertising.

Tips for Reducing Marketing Expenses

- Utilize free social media platforms for organic growth.

- Network within the eco-friendly community to share resources for co-marketing.

- Create engaging DIY content to drive organic traffic without heavy advertising costs.

Effective marketing strategies will ultimately lead to a higher return on investment by enhancing brand awareness and driving sales. Understanding the cost breakdown of bamboo toothbrush production and allocating your budget effectively is essential for sustainable growth. By emphasizing both sustainability and stylish branding, EcoBrush Co. can confidently position itself within the increasingly competitive eco-friendly personal care market.

Website Development And E-Commerce Setup

In today's digital age, establishing a strong online presence is crucial for any business, including a bamboo toothbrush production venture like EcoBrush Co. The costs associated with website development and e-commerce setup can be significant, but they are essential for reaching eco-conscious consumers and driving sales.

When planning your startup costs for the bamboo toothbrush business, consider the following key components that contribute to website development and e-commerce setup expenses:

- Domain Name Registration: Securing a unique domain name typically costs around $10 to $50 per year.

- Website Hosting: Reliable hosting services range from $5 to $50 per month, depending on features and traffic capacity.

- Website Design: Engaging and professional design can range from $500 to $5,000 if you hire a web designer or use premium templates.

- E-commerce Platform Fees: Utilizing platforms like Shopify can incur monthly fees starting from $29 per month, plus transaction fees.

- SSL Certificate: To ensure secure transactions, an SSL certificate costs between $50 and $200 annually.

- Payment Processing Fees: Payment gateways typically charge around 2.9% + $0.30 per transaction.

When you combine these elements, the total initial investment for website development and e-commerce setup can range from $1,000 to $10,000 depending on your specific needs and the quality of the services chosen.

Cost-Saving Tips for Website Development

- Utilize open-source e-commerce platforms to minimize licensing fees.

- Consider DIY website builders like Wix or Squarespace for lower costs.

- Leverage social media and free marketing channels initially to reduce costs.

Additionally, the bamboo toothbrush production business should focus on integrating sustainable practices into the e-commerce model. Strategies include using eco-friendly hosting services or ensuring that website operations are as energy-efficient as possible.

| Expense Type | Estimated Cost | Notes |

|---|---|---|

| Domain Name Registration | $10 - $50/year | Annual cost to maintain your online identity. |

| Website Hosting | $5 - $50/month | Depends on the provider and bandwidth needed. |

| E-commerce Platform Fees | Starting at $29/month | Basic features for starting an online store. |

| SSL Certificate | $50 - $200/year | Essential for payment security. |

By thoroughly understanding bamboo toothbrush production costs associated with website development and e-commerce setup, you can create a comprehensive bamboo toothbrush business plan that aligns with EcoBrush Co.'s sustainable mission while keeping expenses manageable.

To assist with your financial planning, consider using a detailed financial model tailored for bamboo toothbrush production, which can guide you through budgeting, forecasting, and securing startup funding. You can find this model at Bamboo Toothbrush Production Financial Model.

Initial Inventory Production

For a startup focusing on bamboo toothbrush production such as EcoBrush Co., understanding the initial inventory production costs is crucial. This segment of the startup costs bamboo toothbrush business can significantly influence your overall budget and operational strategy. The initial inventory includes the immediate materials needed for manufacturing, which directly affects your cash flow and inventory turnover rates.

In the early stages, it's essential to determine how many units you plan to produce and sell within your target market. A well-planned production quantity can help mitigate excess inventory, which could lead to additional holding costs or waste. Below are some key components to consider while estimating initial inventory production expenses:

- Bamboo Raw Material Costs: The cost of high-quality bamboo can fluctuate based on market demand, sourcing location, and procurement methods. For instance, average costs can range from $1.50 to $3.00 per toothbrush depending on the suppliers.

- Manufacturing Equipment Expenses: Investment in specialized bamboo toothbrush production equipment, such as cutting machines or molding devices, can cost anywhere from $5,000 to $20,000 depending on the scale of production intended.

- Packaging Costs: Eco-friendly packaging solutions can be more expensive but are vital for a sustainable brand image. Estimated costs for attractive, eco-conscious packaging might range from $0.30 to $0.50 per unit.

- Initial Inventory Production Volume: A production run of 1,000 to 5,000 toothbrushes can lead to a substantial upfront cost, potentially ranging from $3,000 to $15,000 depending on material and manufacturing processes.

- Design and Prototyping Costs: Budgeting for initial designs and prototypes can add another $500 to $2,000 as you'll want to create a product that stands out in the sustainable market.

To provide a clearer picture, here is a brief overview of the estimated initial costs involved in production for a basic batch of bamboo toothbrushes:

| Item | Estimated Cost per Unit | Total Cost (for 1,000 units) |

|---|---|---|

| Bamboo Raw Materials | $2.00 | $2,000 |

| Manufacturing Equipment | $15,000 (one-time) | $15,000 |

| Packaging | $0.40 | $400 |

| Design/Prototyping | $1.00 | $1,000 |

In total, the initial inventory production costs for your bamboo toothbrush production could sum up to approximately $18,400 before operational expenses are considered.

Tips for Cost Management

- Consider sourcing bamboo directly from producers to minimize raw material costs.

- Negotiate bulk purchasing discounts with suppliers for initial inventory to reduce expenses.

- Leverage local manufacturing resources or partnerships to lower equipment investment costs.

In developing a solid bamboo toothbrush business plan, understanding these initial inventory production costs and how they fit into your overall cost breakdown bamboo toothbrush production will allow you to identify potential funding needs before launching.

Office and Warehouse Space Setup

When launching a bamboo toothbrush production business like EcoBrush Co., one of the most significant startup costs involves the setup of office and warehouse space. This cost is essential for proper operations, inventory management, and administrative activities. The choice of location will also impact your overall expenses, including rent, utilities, and potential renovations.

Here's a breakdown of the potential costs associated with your office and warehouse space:

| Expense Type | Estimated Cost (Monthly) | Notes |

|---|---|---|

| Office Rent | $1,000 - $2,500 | Varies based on location and size. |

| Warehouse Rent | $1,500 - $4,000 | Depends on the space needed for inventory and production. |

| Utilities (Electricity, Water, Internet) | $200 - $500 | Costs may vary with usage. |

| Renovation and Setup | $5,000 - $15,000 | Includes shelving, office furniture, and production zone setup. |

While it's essential to invest in a suitable setup, you can look for cost-effective solutions to keep your startup costs manageable. Here are some tips:

Tips for Reducing Office and Warehouse Costs

- Consider co-working spaces for office setup to minimize costs.

- Negotiate lease terms to include utilities or maintenance costs.

- Look for warehouse spaces in emerging areas where rental costs are lower.

- Utilize online tools to find affordable spaces before signing any lease.

In the context of the bamboo toothbrush production industry, budgeting for office and warehouse space is crucial. The total expenses for these setups can range between **$7,000** and **$20,000** initially, depending on the location and facilities required. To better understand your financial planning for a bamboo toothbrush startup, you can refer to comprehensive financial models that outline potential costs and expected returns. For more information on this, check out this link.

Overall, the cost breakdown for office and warehouse space plays a vital role in the overall bamboo toothbrush manufacturing expenses. Ensuring you have an appropriate setup will facilitate smoother operations and better management of the production process, ultimately leading to the success of your startup.