Related Blogs

Are you considering venturing into the innovative world of smart helmet manufacturing? Understanding the top nine startup costs is crucial to your success. From research and development to legal compliance, each expense can significantly impact your budget. Ready to dive deeper into the specifics? Explore a detailed business plan to set your foundation by visiting this link.

How Much Does It Cost To Start A Smart Helmet Manufacturing Company?

Starting a smart helmet manufacturing company like SmartGuard Helmets involves various costs that can significantly impact your overall startup budget. The total investment required to launch such a business can range from $150,000 to over $500,000, depending on several factors including the scale of production, technology integration, and market strategy.

Key components of the smart helmet manufacturing costs include:

- Research and Development (R&D) Costs: Developing innovative safety technology and user-friendly features can require a substantial R&D budget, often ranging from $50,000 to $200,000.

- Manufacturing Equipment Costs: Essential equipment for smart helmet manufacturing can cost between $100,000 to $300,000, depending on the technology needed for production.

- Prototyping Costs: Creating functional prototypes is crucial for testing and validation, costing approximately $10,000 to $50,000.

- Material Sourcing Costs: The costs of sourcing quality materials for helmets can vary widely, averaging around $20,000 to $100,000.

- Quality Assurance and Testing Costs: Ensuring product safety and compliance may incur expenses of $15,000 to $60,000.

- Brand Development and Marketing Costs: Establishing a brand presence in the competitive market can require an investment of $30,000 to $100,000.

- Legal and Compliance Costs: Meeting industry regulations and securing patents can cost between $10,000 to $50,000.

- Facility Setup and Renovation Costs: Depending on location, setting up a manufacturing facility can range from $20,000 to $150,000.

- Initial Inventory Costs: Stocking initial inventory may require an investment of approximately $20,000 to $70,000.

In total, the costs associated with smart helmet production can accumulate quickly, making it essential for entrepreneurs to conduct thorough financial planning. According to a recent analysis, effective budgeting for a smart helmet business can lead to better management of these startup costs.

Tips for Managing Startup Costs

- Consider phased product development to spread out R&D costs over time.

- Explore grants and funding opportunities specific to technology and safety innovations.

- Leverage partnerships with universities or research institutions for cost-effective R&D.

Understanding the financial landscape and being prepared for the various smart helmet business expenses is crucial for success in this competitive market. By carefully analyzing and planning for these costs, aspiring entrepreneurs can better position themselves to launch a successful smart helmet manufacturing company.

Is it Possible to Start a Smart Helmet Manufacturing Company with Minimal Investment?

Starting a smart helmet manufacturing company, such as SmartGuard Helmets, can seem daunting due to the initial smart helmet manufacturing costs, which typically range between $100,000 to $500,000 depending on various factors such as location, technology integration, and scale. However, with strategic planning and resourcefulness, it is possible to launch a smart helmet business with minimal investment.

Here are some effective strategies to reduce initial expenses:

Cost-Effective Strategies

- Consider outsourcing R&D and production to third-party manufacturers to lower startup costs for smart helmet companies significantly.

- Utilize crowdfunding platforms to gather initial investment for your smart helmet startup budget. This can help mitigate the cost burden upfront.

- Leverage existing technologies and components to reduce smart helmet production expenses associated with prototyping.

It's crucial to understand what costs can be minimized without compromising on quality. For instance, R&D costs for smart helmets can be shared among different models, and partnerships with universities or tech firms may provide access to innovation at a lower cost.

Furthermore, investing in a robust financial plan can enable entrepreneurs to allocate resources efficiently. For example, quality assurance and testing costs can be managed through pilot testing in low-risk environments before scaling up production.

According to market analysis, nearly 65% of startups face challenges due to lack of funding. Therefore, having a clear understanding of how to start a smart helmet business by analyzing all associated costs is paramount. This includes knowing the cost of smart helmet manufacturing and being prepared to navigate regulatory compliance costs for smart helmet businesses.

By strategically managing these factors, aspiring entrepreneurs can successfully launch a smart helmet manufacturing company like SmartGuard Helmets while minimizing their initial financial exposure.

Which Costs Can Be Reduced For A Smart Helmet Manufacturing Company?

Starting a smart helmet manufacturing company like SmartGuard Helmets can be a significant financial undertaking. However, by identifying areas where costs can be reduced, entrepreneurs can streamline their startup budget and improve profitability. Here are some key areas to focus on:

1. Research and Development Costs

While R&D is crucial for innovation, smart helmet businesses can minimize these expenses through open-source technologies or by collaborating with universities and research institutions. Utilizing existing technology can save up to 30% of typical R&D costs.

2. Manufacturing Equipment Costs

Investing in high-end machinery can be costly. Consider leasing equipment or investing in used machinery instead of purchasing brand new. This step can potentially reduce initial equipment costs by 20-40%.

3. Prototyping Costs

Prototyping can be expensive, but using 3D printing technology allows for cost-effective and rapid prototyping. This can decrease prototyping expenses by as much as 50%, allowing you to invest in more iterations without breaking the bank.

4. Material Sourcing Costs

Material costs can take a considerable slice of your budget. Consider sourcing materials from local suppliers to reduce shipping costs and realize savings of up to 15%. Additionally, bulk purchasing can further save costs.

5. Quality Assurance and Testing Costs

Quality assurance is non-negotiable, but you can manage costs by integrating automated testing solutions rather than relying solely on manual inspection, which can reduce testing expenses by approximately 25%.

6. Brand Development and Marketing Costs

Marketing can be a significant expense. Leverage social media and content marketing for low-cost advertising. Focusing on online marketing strategies can cut initial marketing costs by up to 50%.

7. Legal and Compliance Costs

Engaging a law firm can be expensive. Consider using pre-made templates for contracts and agreements, which can reduce these legal expenses by nearly 30%.

8. Facility Setup and Renovation Costs

Instead of building a new facility, consider renting or leasing space in an existing manufacturing plant. This approach can save startup costs significantly—by as much as 40%—thereby reducing the financial burden on your smart helmet startup.

9. Initial Inventory Costs

Starting with a smaller initial inventory and utilizing a just-in-time inventory strategy can help minimize costs. This method can reduce holding costs and improve cash flow management.

Tips for Reducing Smart Helmet Manufacturing Costs

- Explore partnerships with tech firms to share R&D expenses.

- Utilize local universities for prototyping support, accessing resources at lower rates.

- Leverage social platforms for marketing to cut advertising costs.

Tracking these potential savings can greatly impact the overall startup costs of a smart helmet company. For more insights on managing costs effectively in your venture, check out resources that provide detailed breakdowns of smart helmet manufacturing expenses.

Examples Of Startup Budgets For Smart Helmet Manufacturing Companies

When planning to start a smart helmet manufacturing company like SmartGuard Helmets, understanding the startup costs is crucial for financial planning and securing funding. Below are examples of the typical budget required to launch a smart helmet business, distinguished across various expense categories.

Estimated Startup Budget Breakdown

- Research and Development Costs: $50,000 - $150,000

- Manufacturing Equipment Costs: $100,000 - $250,000

- Prototyping Costs: $20,000 - $60,000

- Material Sourcing Costs: $30,000 - $80,000

- Quality Assurance and Testing Costs: $15,000 - $40,000

- Brand Development and Marketing Costs: $25,000 - $70,000

- Legal and Compliance Costs: $10,000 - $30,000

- Facility Setup and Renovation Costs: $40,000 - $100,000

- Initial Inventory Costs: $30,000 - $100,000

The total estimated startup costs for a smart helmet manufacturing company can range from $320,000 to $1,000,000, depending on the scale and ambition of the project.

Example Budget for a Small to Medium-Sized Smart Helmet Startup

For a small to medium-sized startup with a focus on initial market entry, the budget might look like this:

- Research and Development Costs: $70,000

- Manufacturing Equipment Costs: $150,000

- Prototyping Costs: $30,000

- Material Sourcing Costs: $50,000

- Quality Assurance and Testing Costs: $20,000

- Brand Development and Marketing Costs: $40,000

- Legal and Compliance Costs: $15,000

- Facility Setup and Renovation Costs: $60,000

- Initial Inventory Costs: $50,000

This sample budget totals around $495,000, illustrating the significant investment required to launch a smart helmet business.

Tips for Budget Management

- Prioritize R&D and prototyping to ensure product viability before committing larger capital.

- Explore leasing options for manufacturing equipment to reduce upfront costs.

- Utilize local resources for material sourcing to minimize shipping expenses.

Startup costs for a smart helmet manufacturing company can be daunting, but careful planning and financial analysis can make the process manageable. For more detailed insights into the costs associated with smart helmet production, resources like this guide provide valuable information on budgeting effectively.

How to Secure Enough Funding to Start a Smart Helmet Manufacturing Company?

Launching a smart helmet manufacturing company, such as SmartGuard Helmets, involves considerable financial investment. The startup costs for a smart helmet company can range substantially, often exceeding $500,000 depending on various factors, including location, scale of operations, and the complexity of technology integration.

To secure sufficient funding, entrepreneurs should explore multiple avenues:

- Bootstrapping: Utilize personal savings or revenue from initial sales to minimize financial burden.

- Angel Investors: Attract high-net-worth individuals who can invest in exchange for equity or convertible debt.

- Venture Capital: Seek out venture capital firms that specialize in tech startups; they can provide larger amounts of funding.

- Government Grants: Research grants tailored for innovative technology or manufacturing initiatives.

- Crowdfunding: Leverage platforms like Kickstarter or Indiegogo to raise funds through pre-orders or donations.

In addition to these funding sources, having a robust financial plan is essential. A well-structured business plan, detailing the smart helmet production expenses, including R&D costs for smart helmets and costs associated with manufacturing, can attract potential investors. A detailed budget analysis, highlighting the startup costs for the smart helmet company, will also enhance credibility.

Tips for Securing Funding

- Prepare a solid pitch deck that clearly outlines your vision, market opportunity, and competitive advantage.

- Showcase prototypes or proofs of concept to demonstrate feasibility and attract investor interest.

- Network within the industry to connect with potential investors and partners who can support your venture.

Benchmarking against industry standards can further inform your funding strategy. According to recent industry analyses, about 70% of startups in technology struggle to secure adequate funding within the first year. Understanding the smart helmet market analysis can also provide insights into potential investor interests and patterns.

Ultimately, navigating the financial landscape for a smart helmet manufacturing business requires a strategic approach, combining multiple funding sources with thorough financial planning. This not only enhances the chances of securing investment for the smart helmet company but also establishes a strong foundation for long-term growth and sustainability.

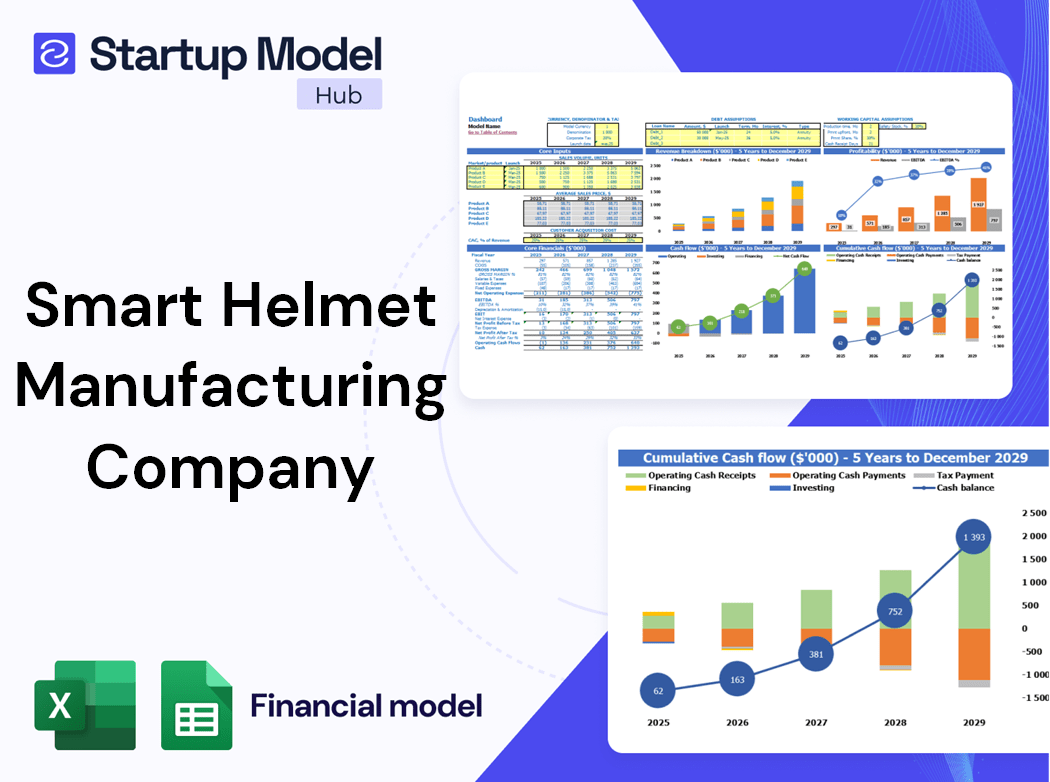

How to Use the Financial Plan for Your Smart Helmet Manufacturing Company?

Establishing a comprehensive financial plan is crucial for the success of your smart helmet manufacturing company, such as SmartGuard Helmets. This plan serves as a roadmap for managing startup costs, predicting revenue, and ensuring sustainable growth. Understanding the various components of your finance strategy allows you to effectively allocate resources, minimize smart helmet production expenses, and optimize your budget.

To begin, it's important to estimate your startup costs for the smart helmet company accurately. Common expenses include:

- Research and Development Costs: Allocate a significant portion of your budget here. Industry experts suggest that R&D can account for up to 20% of your total startup costs.

- Manufacturing Equipment Costs: High-quality machinery is essential. Initial investment could range from $50,000 to $200,000, depending on the scale of production.

- Prototyping Costs: Developing multiple prototypes is necessary. Expect to spend $10,000 to $30,000 for prototypes to ensure functionality and compliance.

- Material Sourcing Costs: Quality materials can vary, but budgeting around $30 to $100 per helmet is advisable.

- Testing and Quality Assurance Costs: Allocate around 10% of overall production costs to ensure safety and compliance with regulations.

- Brand Development and Marketing Costs: Building a brand in the competitive smart helmet market entails a budget of $5,000 to $25,000.

- Legal and Compliance Costs: Compliance with industry standards could require an initial investment of $15,000.

- Facility Setup and Renovation Costs: A suitable facility can range from $20,000 to $100,000, including utilities and renovations.

- Initial Inventory Costs: Having stock ready for launch could cost around $30,000 to $60,000.

Utilizing a detailed financial model will help in tracking these costs accurately. For more on financial indicators, explore resources that outline key performance metrics in the smart helmet sector.

Tips for Effective Financial Planning

- Regularly update your financial plan to reflect changes in manufacturing costs and market conditions.

- Engage in market analysis to forecast demand and adjust your production accordingly, minimizing excess inventory costs.

- Prioritize R&D investments to ensure your helmet incorporates the latest safety technologies, enhancing its market appeal.

Moreover, consider the investment for a smart helmet company in terms of securing funding. Effective funding strategies can include:

- Seeking venture capital or angel investors who focus on tech-driven products.

- Applying for grants specifically designated for innovative manufacturing startups.

- Leveraging crowdfunding platforms to gauge interest while also raising funds for the smart helmet production.

By implementing a robust financial plan, you can manage your smart helmet startup budget efficiently and set the stage for long-term success in the industry. For additional insight into the costs associated with smart helmet production, refer to industry benchmarks and best practices.

What Are The Expenses To Start A Smart Helmet Manufacturing Company?

Starting a smart helmet manufacturing company like SmartGuard Helmets involves various startup costs that entrepreneurs must anticipate. These expenses can be categorized into different segments, each critical for bringing your innovative product to market. An estimated total investment for a smart helmet manufacturing startup can range from $150,000 to $500,000, depending on scale and scope.

Research and Development Costs

Investing in R&D costs for smart helmets is essential to creating a product that integrates advanced safety technology and user-friendly features. These costs typically account for around 15-20% of your startup budget.

Manufacturing Equipment Costs

The cost of smart helmet manufacturing equipment can vary significantly based on your production scale. Budgeting for essential equipment may require an initial outlay of $50,000 to $200,000 depending on the machinery needed for assembly and production.

Prototyping Costs

Creating prototypes to test designs and functionalities is crucial. Smart helmet prototyping expenses can range from $10,000 to $50,000 per prototype, and multiple iterations are often necessary before finalizing a design.

Material Sourcing Costs

The costs of sourcing materials for helmets such as protective layers, electronics, and outer shells can add significant expenses, typically representing about 30-40% of your total production costs.

Quality Assurance and Testing Costs

Ensuring that your helmets meet safety standards involves testing and quality assurance costs smart helmets can run between $5,000 and $25,000 depending on the extent of testing needed for compliance with safety regulations.

Brand Development and Marketing Costs

Effective budgeting for smart helmet business includes investing in brand development and marketing, which can take a significant slice of your initial budget, typically around 15% of your startup costs.

Legal and Compliance Costs

Legal and compliance costs are vital to ensure your product adheres to industry standards. Expect to spend around $10,000 to $40,000 on legal fees related to patents, trademarks, and safety compliance.

Facility Setup and Renovation Costs

Setting up your manufacturing facility will incur additional costs. Depending on location and size, facility setup and renovation costs may range from $20,000 to $150,000.

Initial Inventory Costs

Finally, you'll need to allocate funds for initial inventory. This can vary widely based on your production capability but typically requires at least $30,000 to $100,000 for initial stock.

Tips for Budgeting

- Conduct thorough market research to optimize your smart helmet startup budget.

- Explore partnerships for investment for smart helmet companies to share R&D costs.

- Leverage technology to reduce smart helmet production expenses through automation.

Research and Development Costs

When launching a smart helmet manufacturing company like SmartGuard Helmets, one of the most significant early investments will be in research and development (R&D) costs. This expense is crucial as it lays the groundwork for the innovative features that will differentiate your product in the competitive helmet market.

The typical R&D costs for smart helmets can vary widely, but it's essential to allocate a sufficient budget to cover several key areas:

- Market analysis and user research to identify critical safety features.

- Design and engineering processes to create a prototype.

- Software development for smart functionalities such as connectivity and tracking.

- Testing and validation to ensure safety and compliance with industry standards.

In general, R&D costs can account for anywhere from 15% to 30% of your total startup expenses for a smart helmet business. Depending on the complexity of the technology and design, initial R&D expenditures could range from $50,000 to $200,000 or more.

| R&D Expense Category | Typical Cost Range | Percentage of Total R&D Costs |

|---|---|---|

| Market Research | $10,000 - $30,000 | 20% - 40% |

| Prototyping and Design | $15,000 - $50,000 | 30% - 50% |

| Software Development | $20,000 - $60,000 | 20% - 30% |

| Testing and Compliance | $5,000 - $15,000 | 10% - 20% |

Investing in R&D ultimately plays a vital role in determining the quality and success of your product. It's also essential to keep in mind that these R&D costs are not one-time expenses. Continuing innovation and improvement will require ongoing investment, often reflected in your smart helmet production expenses.

Tips for Managing R&D Costs

- Establish a clear budget and timeline for your R&D phases to prevent overspending.

- Collaborate with universities and research institutions to access expertise and resources potentially at a lower cost.

- Consider using simulations and digital prototypes to test concepts before physical manufacturing.

To ensure financial viability, it's wise to keep track of your R&D spending. Regularly evaluating your smart helmet startup budget will help identify opportunities to streamline costs or allocate resources more effectively. For detailed financial planning, consider utilizing templates that offer insights into projected R&D investments and overall budgeting strategies tailored for a smart helmet manufacturing startup. You can explore such resources at Smart Helmet Financial Model.

Manufacturing Equipment Costs

Starting a smart helmet manufacturing company like SmartGuard Helmets involves significant investment in manufacturing equipment costs. These costs can vary widely depending on the scale of production, level of automation, and specific technologies employed in the manufacturing process.

Here are some essential categories of manufacturing equipment costs you should consider:

- Machinery for Production: This includes injection molding machines, CNC machines, and assembly line equipment. The price for these can range from $50,000 to $500,000 depending on capabilities and automation.

- Testing Equipment: Specialized equipment for quality assurance and testing for safety standards can cost around $10,000 to $100,000.

- Prototyping Tools: Advanced prototyping tools, including 3D printers, are crucial for developing new helmet designs. Costs can be between $2,000 and $50,000.

- Software for Design and Manufacturing: CAD and CAM software licenses range from $1,000 to $10,000 annually.

- Safety Equipment: Additional safety resources for employees, which may be required for compliance, could add another $5,000 to $20,000.

Overall, the total manufacturing equipment costs for a smart helmet company can range significantly, with an average startup budget for smart helmet manufacturing lying between $100,000 to $1 million, depending on the production scale and technology choice.

Tips on Budgeting for Equipment Costs

- Consider purchasing used equipment or leasing to reduce upfront costs.

- Invest in high-quality machinery to minimize maintenance costs in the long run.

- Evaluate robotic automation options as they can offer efficiency gains over time.

When budgeting for your smart helmet startup, it's important to plan for ongoing production expenses, including maintenance costs and operational costs. These costs can add up quickly and should be factored into your financial planning for your smart helmet startup.

For a realistic view of the financial requirements, you may want to explore benchmarking data. For instance, manufacturers in the tech and safety gear sectors typically allocate about 20-30% of their startup budget on manufacturing equipment alone. This statistic can help guide your investment strategy.

| Equipment Type | Cost Range | Notes |

|---|---|---|

| Injection Molding Machine | $50,000 - $500,000 | Key for helmet production |

| 3D Printer | $2,000 - $50,000 | Essential for prototyping |

| Testing Equipment | $10,000 - $100,000 | Ensures compliance with safety standards |

In conclusion, understanding the smart helmet manufacturing costs associated with equipment can significantly enhance your ability to create a viable business plan. By carefully analyzing and planning for these startup costs, you can position SmartGuard Helmets for success and create innovative products that improve safety for users in high-risk activities.

Prototyping Costs

When embarking on the journey of starting a smart helmet manufacturing company like SmartGuard Helmets, understanding prototyping costs is essential. Prototyping serves as a crucial phase in the development of smart helmets, allowing you to test functionality, design, and user interaction before full-scale production. These costs can significantly impact your overall smart helmet startup budget.

Prototyping costs can vary widely based on several factors, including the complexity of the design, the technology incorporated, and the materials used. On average, you may expect to allocate between $10,000 to $50,000 specifically for prototyping. Below is a breakdown of typical expenses associated with prototyping smart helmets:

| Expense Category | Estimated Cost | Remarks |

|---|---|---|

| Design and Engineering | $3,000 - $15,000 | Involves CAD design and engineering consultation. |

| Material Costs | $2,000 - $10,000 | Costs associated with sourcing materials for prototypes. |

| 3D Printing and Manufacturing | $5,000 - $20,000 | Cost for fabricating initial prototypes through 3D printing or molding. |

| Testing and Iteration | $2,000 - $5,000 | Involves conducting tests and possible redesigns based on feedback. |

Through effective budgeting for these smart helmet production expenses, you can better prepare for the financial demands of bringing your product to market. Investing in prototyping plays a pivotal role in ensuring safety, functionality, and market readiness.

Tips for Managing Prototyping Costs

- Opt for rapid prototyping techniques like 3D printing to minimize material waste and reduce costs.

- Conduct thorough research on materials to avoid unnecessary expenses while maintaining quality.

- Engage with experienced designers to streamline the design process and enhance functionality.

In addition to the above, consider allocating funds for specialized testing equipment and services, which can add to your smart helmet manufacturing costs. Testing is crucial to ensure that your smart helmets meet safety standards and function effectively. Quality assurance processes can require an additional 10-20% of your initial prototyping budget.

As you plan for prototyping, it is essential to factor in the potential for unexpected costs. A well-structured financial plan for your smart helmet manufacturing company should account for contingencies arising from design changes or material shortages.

By outlining these expenses and carefully analyzing your startup costs smart helmet company, you pave the way for a smoother transition from prototype to market-ready product. For further insights into managing your budget effectively, you can refer to industry benchmarks and statistical data available at expert financial resources.

Understanding and managing prototyping costs is a vital investment for your smart helmet company. This will not only set the foundation for a successful product launch but also enhance the safety and technological capabilities of your helmets. To dive deeper into the financial aspects of starting your smart helmet business, check out our comprehensive financial model at Smart Helmet Manufacturing Company Financial Model.

Material Sourcing Costs

In the realm of smart helmet manufacturing, **material sourcing costs** represent a significant portion of the total startup expenses. These costs encompass everything from raw materials essential for helmet construction to the high-tech components necessary for the smart functionalities that set your helmet apart. In a competitive industry like this, understanding and managing these costs is crucial for your smart helmet business expenses.

Here are some key materials you will need to source:

- Protective shell material (polycarbonate, fiberglass, etc.)

- Foam liners for impact absorption

- Electronic components (sensors, speakers, batteries)

- Connectivity modules (Bluetooth, Wi-Fi chips)

- Inner padding and straps for comfort and security

- Coatings and finishes for aesthetics and durability

The **cost of smart helmet manufacturing** will vary based on the quality and quantity of materials sourced. For example, the price of high-grade polycarbonate can range from **$3 to $10 per kilogram**, while electronic components often require larger investments, such as **$10 to $50 for each smart sensor**. Thus, establishing relationships with reliable suppliers can lead to bulk pricing discounts and significantly lower your overall smart helmet production expenses.

Consider this breakdown of material sourcing costs for a basic budget model in your smart helmet startup budget:

| Material Type | Estimated Cost per Unit | Estimated Quantity Needed | Total Cost |

|---|---|---|---|

| Protective Shell | $5 | 100 | $500 |

| Foam Liners | $2 | 100 | $200 |

| Electronic Components | $30 | 100 | $3,000 |

| Connectivity Modules | $20 | 100 | $2,000 |

| Inner Padding | $1 | 100 | $100 |

| Total | $5,800 |

To enhance your **financial planning for smart helmet startup**, keep in mind that **testing and quality assurance costs smart helmets** will also affect your budget. Each component must not only meet safety standards but also function effectively in combination. As such, sourcing quality materials is non-negotiable.

Tips for Reducing Material Sourcing Costs

- Negotiate with suppliers to secure long-term contracts for better pricing.

- Research alternative materials that maintain quality but come at lower costs.

- Consider local suppliers to minimize shipping expenses and lead times.

As you venture into how to start a smart helmet business, budgeting for material sourcing is essential for ensuring profitability and sustainability. **Investment for smart helmet company** should be strategically allocated to ensure that the materials used not only comply with safety regulations but also enhance the overall user experience.

Ultimately, effectively managing **costs of sourcing materials for helmets** will position your smart helmet manufacturing company, SmartGuard Helmets, for success in a burgeoning market. To explore a comprehensive financial plan tailored for your business, consider visiting Smart Helmet Manufacturing Financial Model.

Quality Assurance and Testing Costs

In the journey of launching a smart helmet manufacturing company like SmartGuard Helmets, one of the critical areas that require significant investment is quality assurance and testing costs. These costs ensure that the helmets not only meet industry safety standards but also provide the innovative features that set them apart. Failure to invest adequately in this area can lead to product recalls, liability issues, and damage to brand reputation.

The cost of smart helmet manufacturing can vary widely depending on the complexity of the technology involved and the regulatory requirements of different markets. However, budgeting for quality assurance and testing is essential to mitigate risks and ensure product reliability. On average, these costs can range from $50,000 to $150,000 during the initial stages of production, depending on the scale and technology integrated into the helmets. Specifically, here are some components of these costs:

- Laboratory Testing: Engaging third-party labs to conduct safety tests, which may include drop tests, impact resistance, and environmental stress tests. Expected costs can be around $10,000 to $30,000.

- Prototyping for Testing: Investing in multiple prototypes to evaluate performance under various conditions. Prototype costs can add up to $20,000 to $50,000.

- Compliance Certification: Adhering to safety standards such as DOT or Snell certification can incur fees ranging from $5,000 to $20,000.

- Quality Control Personnel: Hiring qualified personnel to oversee production quality can cost $30,000 to $60,000 annually.

- Materials Testing: Sourcing materials and conducting tests to ensure performance, which typically costs around $5,000 to $15,000.

Overall, budgeting for testing and quality assurance costs for smart helmets is not just a regulatory requirement, but a strategic investment in customer satisfaction and brand integrity. Allocating a portion of your smart helmet startup budget to this area can lead to long-term savings by preventing future liabilities.

Tips for Managing Quality Assurance Costs

- Conduct in-house testing where feasible to save costs while maintaining standards.

- Establish partnerships with testing labs to negotiate bulk testing discounts.

- Utilize technology for remote testing capabilities, reducing travel and operational costs.

| Testing Type | Estimated Cost | Duration |

|---|---|---|

| Laboratory Testing | $10,000 - $30,000 | 2-4 weeks |

| Prototyping | $20,000 - $50,000 | 4-8 weeks |

| Compliance Certification | $5,000 - $20,000 | 1-3 months |

Starting a smart helmet business involves navigating various challenges, but well-planned quality assurance and testing costs can safeguard against potential setbacks. With a comprehensive financial plan for your smart helmet manufacturing company, you can allocate resources effectively, ensuring products not only meet safety standards but also achieve market success. For more detailed planning, visit Smart Helmet Financial Model.

Brand Development and Marketing Costs

One of the essential components for launching a successful smart helmet manufacturing company, such as SmartGuard Helmets, is effective brand development and marketing. This process not only establishes your business identity but also positions your products in the competitive marketplace. When considering startup costs for a smart helmet company, allocating adequate funds for brand development and marketing is crucial.

The costs associated with brand development and marketing can vary significantly based on strategy, target market, and the competitive landscape. Here are the primary areas where you should expect to incur expenses:

- Branding Strategy Development: Crafting a comprehensive branding strategy that resonates with your target audience can cost anywhere from $5,000 to $15,000, depending on the expertise required.

- Website Development: An engaging and user-friendly website is essential; expect to spend $2,000 to $10,000 for design, development, and initial content creation.

- Social Media Marketing: Establishing a presence on platforms like Instagram, Facebook, and LinkedIn can require anywhere from $500 to $5,000 per month, depending on the intensity of the campaigns.

- Content Marketing: Creating high-quality content such as blog posts and videos to promote your smart helmets can range from $1,000 to $5,000 per month.

- Advertising Costs: Both digital and traditional advertising (PPC, print media, etc.) can add up to $1,000 to $10,000 monthly, depending on your outreach goals.

In addition to these initial costs, ongoing expenses should also be factored into your smart helmet startup budget. A well-thought-out marketing plan could amount to approximately 15-20% of your overall budget.

| Expense Category | Estimated Cost Range |

|---|---|

| Branding Strategy Development | $5,000 - $15,000 |

| Website Development | $2,000 - $10,000 |

| Social Media Marketing (Monthly) | $500 - $5,000 |

| Content Marketing (Monthly) | $1,000 - $5,000 |

| Advertising Costs (Monthly) | $1,000 - $10,000 |

To efficiently manage smart helmet business expenses, consider the following tips:

Cost-Effective Marketing Strategies

- Utilize social media platforms for organic growth before investing heavily in paid advertising.

- Leverage partnerships with influencers in the sports and safety industries to gain visibility.

- Invest in SEO to improve your website’s organic traffic, minimizing reliance on PPC campaigns.

In conclusion, understanding and budgeting for brand development and marketing costs is essential for the success of your smart helmet manufacturing company. These costs play a pivotal role in how effectively you can reach your audience and establish a reliable brand in the industry.

For a comprehensive evaluation of your potential expenses and financial planning, consider utilizing professional resources tailored for smart helmet startups: Smart Helmet Manufacturing Financial Model.

Legal and Compliance Costs

When embarking on the journey to establish a smart helmet manufacturing company like SmartGuard Helmets, one of the most crucial aspects to consider is the legal and compliance costs. These expenses can vary significantly based on the jurisdiction and the complexity of the regulations applicable to helmet manufacturing.

Legal and compliance costs encompass various elements, including but not limited to, intellectual property rights, safety certifications, and industry-specific regulations. The total cost for compliance could range from $15,000 to $50,000 depending on the scale of operations and the specific requirements of the target market.

- Intellectual Property Protection: Securing patents for innovative designs and technology is vital. This process can cost between $5,000 to $20,000 depending on the complexity and duration.

- Safety Certifications: Helmets must meet specific safety standards (e.g., DOT, ECE) before they can be marketed. Certification fees can range from $10,000 to $30,000.

- Legal Fees: Ongoing legal expenditures for contract reviews, compliance consultations, and other legal matters can add up to $2,000 to $10,000 annually.

- Regulatory Filings: Additional costs involved in filing required documents with state and federal agencies typically range from $1,000 to $5,000.

In addition to these direct costs, it's essential to consider indirect expenses, such as missed opportunities due to compliance delays or costs incurred to rectify compliance failures. The financial repercussions of non-compliance can be substantial, leading to fines, product recalls, and reputational damage.

Helpful Tips for Managing Legal and Compliance Costs

- Prioritize safety certifications early in the development process to avoid delays.

- Consult with legal experts familiar with helmet manufacturing to ensure all bases are covered.

- Research grants or programs that support startups in navigating regulatory landscapes, which can reduce costs.

Furthermore, investing in a well-structured compliance strategy can significantly mitigate risks associated with legal and compliance issues. It’s prudent for aspiring smart helmet entrepreneurs to factor these smart helmet manufacturing costs into their startup budget.

| Cost Element | Estimated Cost Range | Notes |

|---|---|---|

| Intellectual Property Protection | $5,000 - $20,000 | Cost varies by complexity and jurisdiction. |

| Safety Certifications | $10,000 - $30,000 | Necessary for legal sale in target markets. |

| Legal Fees | $2,000 - $10,000 annually | Includes consultations and contract reviews. |

| Regulatory Filings | $1,000 - $5,000 | Costs for required documentation submissions. |

Understanding and adequately preparing for the legal and compliance costs is critical for the long-term health of your smart helmet business. By incorporating these considerations into your financial planning and budgeting for your smart helmet business, you can ensure a smoother startup process and better positioning in the market.

For more detailed insights into financial planning for your startup, consider exploring comprehensive financial models tailored for smart helmet manufacturing. Visit Smart Helmet Manufacturing Company Financial Model.

Facility Setup and Renovation Costs

When launching a smart helmet manufacturing company, such as SmartGuard Helmets, understanding the facility setup and renovation costs is crucial. These costs can differ significantly depending on the location, size, and specific needs of your manufacturing operations. Here's what you should consider when estimating these expenses:

- Location Rental Costs: The rent or purchase price of your facility can be a major part of your budget. Industrial spaces in urban areas may range from $10 to $30 per square foot, while more suburban options could be cheaper.

- Renovation and Setup: This involves the costs of modifying the space to suit your manufacturing needs. Renovation costs can vary widely but typically lie between $50,000 and $200,000, depending on the complexity of the modifications.

- Utilities Setup: Setting up essential utilities (electricity, water, internet) can add anywhere from $5,000 to $20,000 to your budget.

- Health and Safety Compliance: Ensuring your facility meets health and safety regulations may entail additional costs ranging from $10,000 to $50,000 depending on local regulations.

- Security Systems: Investing in security measures, including surveillance cameras and alarms, typically costs about $5,000 to $15,000.

- Office Space: If your manufacturing facility requires an office area for administration, budgeting an additional $20,000 to $50,000 for office setup is advisable.

Taking into account these various factors, the overall facility setup costs for a smart helmet manufacturing company can range significantly, but a rough estimate could be between $100,000 and $500,000, depending on your individual needs and circumstances.

Tips for Reducing Facility Costs

- Consider industrial parks that offer lower rent and tax incentives.

- Negotiate lease terms to spread out renovation costs over time.

- Utilize modular or prefabricated solutions to minimize renovation time and expenses.

Investing in a well-thought-out facility is pivotal to the success of your smart helmet business. It will not only cater to your production needs but also reflect your brand's quality. Proper financial planning helps in delineating all these smart helmet production expenses effectively.

| Cost Category | Estimated Cost Range | Notes |

|---|---|---|

| Location Rental Costs | $10 - $30/sq ft | Varies by area |

| Renovation Costs | $50,000 - $200,000 | Depends on complexity |

| Utilities Setup | $5,000 - $20,000 | Essential services |

| Health and Safety Compliance | $10,000 - $50,000 | Varies by regulations |

| Security Systems | $5,000 - $15,000 | Includes cameras and alarms |

| Office Space Setup | $20,000 - $50,000 | Necessary for administration |

Furthermore, using comprehensive financial models can assist in accurately tracking these startup costs for your smart helmet company. To start your journey, consider leveraging financial planning resources tailored for startups in the manufacturing sector.

For a detailed financial plan and model suitable for your smart helmet manufacturing business, visit this link.

Initial Inventory Costs

When embarking on a journey to establish a smart helmet manufacturing company like SmartGuard Helmets, understanding the initial inventory costs is crucial. Inventory management plays a significant role in the startup costs of a smart helmet business, affecting cash flow, production schedules, and overall profitability.

The costs associated with initial inventory can vary widely based on factors such as the chosen materials, production method, and the variety of helmet models you plan to offer. Below are some essential components to consider when budgeting for your initial inventory:

- Raw Materials: This includes the costs of materials such as high-impact plastics, padding, electronic components, and connectivity devices. The cost for sourcing these materials can range from $15 to $50 per helmet, depending on the specifications.

- Components and Accessories: Smart helmets often come with additional features like LED lights, Bluetooth connectivity, and heads-up displays. Investing in these components is integral to your smart helmet production expenses.

- Production Volume: Economy of scale plays a vital role in inventory costs. Ordering larger quantities can lead to discounts, but consider the financial implications for your smart helmet startup budget.

- Quality Assurance (QA) Samples: Before mass production, it’s advisable to budget for QA samples, which can cost around $500 to $1,000 for testing and validation.

- Initial Stock Levels: Determine how many units will be required for your initial launch. A conservative estimate often starts at 500 to 1,000 units, resulting in a total initial inventory investment of $10,000 to $50,000, based on material costs.

Creating a detailed financial plan lays the groundwork for efficient inventory management. Utilize tools such as inventory management software to mitigate costs and keep track of stock levels. This ensures you can respond promptly to market demand and minimize excess inventory that can tie up capital.

Tips for Budgeting Your Initial Inventory

- Conduct thorough market research to understand demand and adjust your initial order quantities accordingly.

- Negotiate with suppliers for bulk purchase discounts on raw materials to reduce overall costs.

- Consider phased releases of products, allowing for testing of market response before committing to larger inventory volumes.

To give a clearer picture, here’s a breakdown of potential costs associated with initial inventory for a smart helmet manufacturing startup:

| Item | Cost per Unit | Total Estimated Cost (for 1,000 units) |

|---|---|---|

| Raw Materials | $25 | $25,000 |

| Components and Accessories | $15 | $15,000 |

| QA Samples | Varies | $500 |

| Total Initial Inventory Costs | $40,500 |

In summary, initial inventory costs are a significant portion of the overall startup costs for a smart helmet company. By planning meticulously and utilizing effective budgeting strategies, you can optimize your investment and set the stage for a successful launch. For further guidance on financial planning tailored for your smart helmet startup, visit Smart Helmet Manufacturing Company Financial Model.