Related Blogs

Are you ready to dive into the world of textile recycling but unsure about the initial financial commitments? Understanding the top nine startup costs is crucial to laying a solid foundation for your business. From equipment and facility rental to marketing and licensing fees, each expense can significantly impact your budget. Curious about how to navigate these costs effectively? Explore a comprehensive business plan that will guide you through the financial landscape of starting a textile recycling venture at this link.

How Much Does It Cost To Start A Textile Recycling Business?

Starting a textile recycling business can be an impactful way to address the growing issue of textile waste while tapping into a lucrative market. However, understanding the startup costs for textile recycling is crucial for prospective entrepreneurs. On average, the initial investment can range from $50,000 to $150,000, depending on the scale and scope of operations.

Key components contributing to the overall costs include:

- Equipment for Sorting and Processing Textiles: The cost of textile recycling equipment can vary greatly, with basic machinery starting around $10,000 and more advanced setups exceeding $100,000.

- Initial Inventory of Recyclable Materials: Securing a reliable source of recyclable textile inventory may require an initial investment of $5,000 to $20,000.

- Facility Rental or Purchase Costs: Renting a space can cost anywhere from $1,000 to $5,000 per month, while purchasing a facility may require a significantly larger upfront investment.

- Marketing and Brand Development Expenses: Allocating funds for marketing for textile recycling businesses is essential, with initial costs ranging from $2,000 to $10,000.

- Licensing and Permitting Fees: Depending on local regulations, obtaining the necessary licenses could cost between $500 and $5,000.

- Insurance and Liability Coverage: Insurance costs can vary, but budgeting around $1,000 to $3,000 annually is a good starting point.

- Training and Hiring Staff Costs: Hiring skilled personnel may require an investment of $30,000 to $60,000 annually, depending on the size of your team.

- Technology and Software for Operations: Implementing the right technology solutions can cost around $5,000 to $15,000.

- Initial Research and Development for Upcycling Processes: Investing in R&D may require an additional $10,000 to $25,000.

In total, the textile recycling business expenses can accumulate quickly, and it’s essential to create a detailed financial plan to ensure all costs are accounted for. For more insights, consider checking out resources like this article on opening a textile recycling business.

Tips for Managing Startup Costs

- Consider leasing equipment instead of purchasing to minimize initial outlay.

- Network with local businesses to source recyclable textiles at lower costs.

- Utilize digital marketing strategies that are cost-effective, such as social media campaigns.

Understanding how much it costs to start a textile recycling business not only helps in planning but also in securing necessary funding. Many entrepreneurs wonder if it’s possible to start a textile recycling business with minimal investment; while challenging, it is feasible with careful budgeting and strategic partnerships.

Is it Possible to Start a Textile Recycling Business with Minimal Investment?

Starting a textile recycling business with minimal investment is not only possible but also increasingly feasible in today's eco-conscious market. With the right strategies and planning, entrepreneurs can minimize initial expenses while maximizing potential returns. The global textile recycling industry is projected to reach $5.5 billion by 2027, showcasing a growing demand for sustainable practices.

Essentially, a startup can focus on reducing textile recycling business costs by leveraging available resources, community partnerships, and innovative approaches. Here are some key considerations when aiming to minimize startup costs for textile recycling:

- Utilize Free or Low-Cost Resources: Tap into local businesses and community centers for collecting recyclable materials, allowing for a low initial inventory cost.

- Rent Equipment Whenever Possible: Instead of purchasing costly textile recycling equipment, consider leasing or renting machinery to reduce upfront spending.

- Outsource Services: Hiring subcontractors for specialized tasks can significantly reduce the need for hiring full-time staff, allowing you to control labor costs.

- Embrace Digital Marketing: Utilize social media platforms for marketing rather than spending on traditional advertising methods, which can be more expensive.

- Focus on Upcycling: Engaging in upcycling can create additional revenue streams without the need for large-scale processing facilities.

For those wondering how to start a textile recycling business on a budget, it’s vital to outline a textile recycling business financial plan to track cash flow and expenses. This plan should include a thorough analysis of anticipated textile recycling business expenses, including:

- Initial inventory of recyclable textiles

- Marketing and brand development costs

- Licensing and permitting fees

- Insurance and liability coverage

Cost-Effective Strategies

- Consider community-based collection events to gather materials at little to no cost.

- Seek partnerships with local businesses for shared marketing efforts and resource pooling.

- Research grants and funding options specifically aimed at sustainable initiatives and recycling startups.

Moreover, using technology to streamline operations can cut down on operational costs for recycling. Investing in basic software solutions can help manage inventory and track progress without the high expenditure of custom-built systems.

Ultimately, with careful planning and resourcefulness, launching a textile recycling business with minimal investment is indeed achievable. For more insights into funding a textile recycling startup, check out this detailed article on [textile recycling profitability](https://financialmodeltemplates.com/blogs/profitability/textile-recycling) for useful benchmarks and strategies.

Which Costs Can Be Reduced For A Textile Recycling Business?

When starting a textile recycling business, it's essential to identify areas where expenses can be minimized. By strategically reducing costs, you can optimize your startup budget and improve your financial stability. Here are key areas where you can save:

1. Equipment Costs

Investing in textile sorting equipment can be significant, but you can consider second-hand options or leasing equipment to reduce upfront costs. Research local suppliers and explore community resources for affordable equipment rentals.

2. Facility Rental

Consider starting your operations in a smaller space or a shared facility to minimize initial facility rental costs. Utilizing existing community centers or warehouses can significantly cut down your overhead expenses.

3. Marketing Expenses

Instead of committing to high-cost advertising, leverage social media platforms and local events to promote your sustainable textile recycling services. Engaging with eco-conscious communities can lead to organic growth without hefty marketing budgets.

4. Staff Training Costs

Implementing a thorough training program can be costly, but you can reduce expenses by cross-training your staff. Also, consider offering internships or volunteer positions to support your team while keeping costs low.

5. Technology Needs

Instead of investing in costly proprietary software, look for affordable technology solutions or open-source platforms to manage your operations efficiently. This can help you save substantially on textile recycling business expenses.

6. Initial Inventory

To cut down on recyclable textile inventory costs, establish partnerships with local businesses or community organizations for donations of unwanted textiles. This can help you build your inventory without incurring hefty procurement costs.

Tips for Minimizing Textile Recycling Expenses

- Network with local businesses for discounted or free resources related to textile sorting and processing.

- Engage volunteers or interns to help with everyday tasks, thereby reducing staffing costs while promoting community involvement.

- Utilize free online marketing tools to enhance brand awareness without breaking the bank.

By focusing on these cost-reduction strategies, you can ensure a more sustainable financial path for your textile recycling business. Identifying and minimizing startup costs for textile recycling can significantly boost your chances of success. As highlighted in various resources like financial models and analyses, keeping a tight grip on initial expenditures is crucial for long-term sustainability.

Examples of Startup Budgets for Textile Recycling Businesses

Starting a textile recycling business involves several essential expenditure areas. Here are some example startup budgets that potential entrepreneurs can use to gauge their investment needs. The following categories represent average costs and can vary based on location, scale, and operational strategy.

1. Equipment for Sorting and Processing Textiles

Investing in the right textile recycling equipment is crucial for efficient operations. Equipment costs typically range from $20,000 to $150,000, depending on the machinery's capacity and technology. Essential equipment may include:

- Textile sorting machines

- Shredders for fabric processing

- Compressors for bales

2. Initial Inventory of Recyclable Materials

Acquiring an initial inventory of recyclable textiles is another significant cost. You may need to allocate around $5,000 to $30,000 for sourcing materials from various suppliers or donation centers.

3. Facility Rental or Purchase Costs

Securing a suitable facility is a major upfront expense. Renting a space could cost between $2,000 and $10,000 monthly, while purchasing a facility may require a higher initial investment, often exceeding $200,000 in urban areas.

4. Marketing and Brand Development Expenses

Establishing a brand presence can require around $1,000 to $20,000 for marketing for textile recycling businesses, including digital marketing, promotional materials, and community outreach efforts.

5. Licensing and Permitting Fees

Licensing a textile recycling business comes with fees that can range from $500 to $5,000, depending on local regulations and operational scope. Understanding the legal requirements is crucial.

6. Insurance and Liability Coverage

Protecting your business with appropriate insurance can cost between $1,000 and $3,000 annually, depending on the coverage required. Factors influencing the cost include facility size and operational risks.

7. Training and Hiring Staff Costs

Hiring staff can be a substantial ongoing cost. Initial expenses for hiring staff for textile recycling may range from $10,000 to $50,000 based on the number of employees and their training requirements.

8. Technology and Software for Operations

Investing in technology is essential for efficient operations. Software for inventory management and operations may require $1,000 to $10,000, depending on the complexity and customization.

9. Initial Research and Development for Upcycling Processes

Innovating into sustainable practices could require an R&D budget of about $5,000 to $20,000 for developing effective upcycling processes for textile recycling.

Tips for Budgeting and Funding

- Consider starting small and scaling up to manage startup costs for textile recycling.

- Explore textile business funding options, including grants and eco-focused investors.

- Utilize local partnerships for sourcing materials and collaborative marketing to reduce costs.

These examples illustrate how varied the textile recycling business expenses can be. A well-structured textile recycling business financial plan is vital to ensure that funds are efficient and aligned with business goals. As a reference, additional insights can be found in articles discussing key performance indicators and costs associated with textile recycling initiatives.

How to Secure Enough Funding to Start a Textile Recycling Business?

Securing adequate funding is one of the crucial steps in launching a textile recycling business, particularly for a venture like EcoThreads Recycle, which aims to mitigate textile waste. The startup costs for textile recycling can range from $50,000 to over $200,000, depending on the scale and scope of operations, making effective funding strategies vital.

Here are several strategies to consider for funding a textile recycling startup:

- Personal Savings: Starting with your own capital can demonstrate commitment and reduce reliance on external funding sources.

- Grants and Subsidies: Look for government grants aimed at sustainable businesses. The Environmental Protection Agency (EPA) and local government initiatives often provide financial support for eco-friendly projects.

- Investors: Seek out angel investors or venture capitalists who are interested in sustainable textile recycling. Present a solid business plan that details anticipated returns on investment.

- Crowdfunding: Utilize platforms like Kickstarter or GoFundMe to reach eco-conscious consumers who believe in your mission. This approach not only raises capital but also builds a loyal customer base.

- Bank Loans: Traditional financing can be a reliable option. Prepare a detailed financial plan highlighting startup costs for textile recycling and projected earnings to attract favorable loan terms.

- Partnerships: Collaborate with larger organizations or NGOs focused on sustainability. A partnership could provide not just funding but also invaluable resources and networks.

It’s essential to create a comprehensive financial plan that outlines all anticipated textile recycling business expenses. This plan should detail both fixed costs, such as equipment and facility rental, and variable costs, including marketing and operational expenses.

Tips for Securing Funding

- Prepare a compelling pitch that outlines the impact of your business on reducing textile waste.

- Show potential investors how your business can be profitable while supporting sustainable practices.

- Gather data and statistics supporting the viability of the textile recycling market, such as projected growth rates that indicate increasing demand for sustainable solutions.

Moreover, understanding specific textile recycling equipment costs and operational requirements will help you allocate your funds more effectively. For example, investing in efficient textile sorting equipment can streamline operations and reduce long-term costs.

For additional insights into startup budgets and financial strategies, consider reviewing resources available online, such as this guide on opening a textile recycling business, which provides benchmarks and valuable financial planning tips.

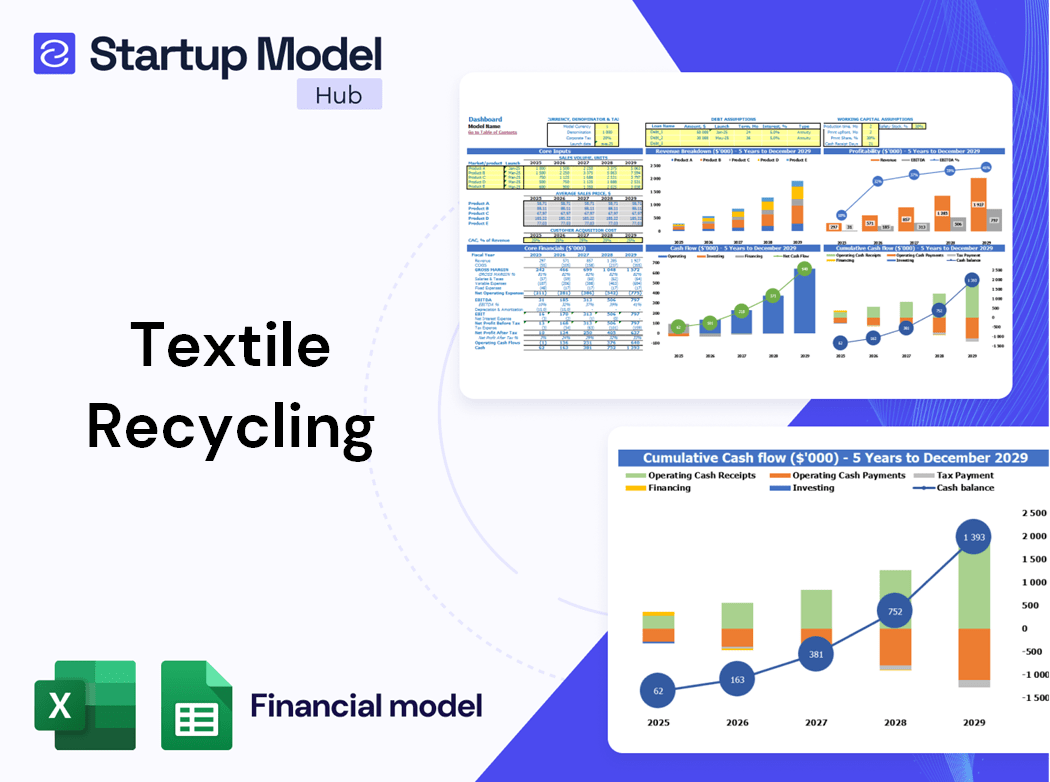

How to Use the Financial Plan for Your Textile Recycling Business?

A robust financial plan is crucial for the success of your textile recycling business, EcoThreads Recycle. It serves as a roadmap, helping you navigate through the startup costs and ongoing expenses associated with sustaining your operations. Here’s how to effectively use this financial plan to your advantage:

1. **Budgeting for Startup Costs**: The first step in your financial plan should include a detailed breakdown of the startup costs for textile recycling. This includes essential expenditures such as:

- Equipment for sorting and processing textiles: On average, these costs can range from $10,000 to $50,000 based on the scale of operations.

- Facility rental or purchase costs: Renting a facility may require an upfront investment of around $2,000 to $5,000 per month, depending on your location.

- Initial inventory of recyclable materials: Initial costs may vary, but setting aside approximately $5,000 is advisable to secure your first stock.

- Licensing and permitting fees: These can range from $500 to $2,000 based on your local regulations.

- Insurance and liability coverage: Expect to spend about $1,000 to $3,000 annually for comprehensive coverage.

Understanding these costs will help you allocate resources efficiently and avoid unexpected financial burdens.

2. **Forecasting Revenue and Cash Flow**: A part of your financial plan should include forecasts for revenue generated from selling recycled textiles and any upcycled products. Researches suggest a typical textile recycling business can achieve 20-40% profit margins once established. Ensure to include:

- Projected sales from various products

- Expected operational costs for recycling

- Break-even analysis to determine when your business will start being profitable

This will provide a clear vision of your business’s financial health over time.

3. **Minimizing Textile Recycling Expenses**: As you develop your financial plan, identify areas where you can minimize expenses. For instance, utilizing grant programs or partnering with local organizations for recyclable textile inventory can significantly reduce costs. Consider these strategies:

Cost-Effective Strategies

- Employ volunteers for sorting and recycling processes to minimize labor costs.

- Invest in multi-functional textile sorting equipment to reduce operational costs.

- Utilize social media platforms for free marketing to promote your recycling initiatives.

4. **Securing Funding**: Your financial plan should also outline various textile business funding options you will pursue. This could include loans, grants, or even crowdfunding campaigns to gather the necessary capital. Statistics show that startups often require anywhere from $10,000 to $100,000 in initial funding, depending on their scale. Highlight targets and timelines for your funding efforts in the plan.

5. **Regular Review and Adjustment**: Finally, your financial plan should be treated as a living document. Regularly review your expenses and revenues against your projections. Adjust your financial strategies based on actual performance and market changes. Keeping your plan dynamic will help you better respond to challenges and opportunities as they arise.

For more insights on creating a financial plan specifically tailored for a textile recycling business, refer to this guide which provides detailed benchmarks and frameworks.

What are the Expenses to Start a Textile Recycling Business?

Starting a textile recycling business like EcoThreads Recycle requires a thorough understanding of various startup expenses. Understanding and planning these costs is essential for developing a solid financial plan and ensuring sustainability in this eco-conscious industry.

Equipment for Sorting and Processing Textiles

The most significant investment will typically be in textile recycling equipment. This includes:

- Sorting machines: Approximately $20,000 to $50,000 depending on capacity.

- Processing machinery: Costs can reach up to $100,000 for industrial-grade equipment necessary for shredding and fabric separation.

- Storage solutions: Forklifts and racking systems can add another $10,000 to $30,000.

Initial Inventory of Recyclable Materials

To commence operations, acquiring an initial inventory of recyclable textiles is crucial. This cost can vary widely based on sourcing methods:

- Purchasing directly from donors or waste management companies may require an upfront investment of $5,000 to $15,000.

- Free collection from local businesses and communities can significantly reduce this expense.

Facility Rental or Purchase Costs

The physical space is another critical expense. Depending on location and size, facility rental costs could range from:

- $2,000 to $5,000 per month for smaller facilities in urban areas.

- Higher for larger spaces in prime locations, potentially exceeding $10,000.

Marketing and Brand Development Expenses

To attract eco-conscious consumers, significant investment in marketing is needed:

- Digital marketing campaigns may require $1,000 to $5,000 monthly.

- Branding materials and promotional events can add another $2,000 to $10,000 initially.

Licensing and Permitting Fees

Compliance with local regulations involves licensing costs, which can range from:

- $500 to $5,000 depending on jurisdiction and specific industry regulations.

- Be prepared for potential unforeseen costs related to environmental assessments.

Insurance and Liability Coverage

Investing in appropriate insurance for recycling startups is crucial for mitigating risks:

- General liability insurance averages between $500 and $2,500 annually.

- Specialized coverage for equipment and operations may incur additional costs.

Training and Hiring Staff Costs

Building a competent team is vital. Budgets should include:

- Recruitment costs: Approximately $2,000 to $5,000.

- Training programs for new hires can total $1,000 to $3,000 per employee.

Technology and Software for Operations

Investing in technology is essential for efficient operations:

- Management software can range from $1,000 to $3,000 annually.

- IT support costs should also be factored in, potentially adding an additional $500 to $2,000.

Initial Research and Development for Upcycling Processes

Developing innovative upcycling processes is essential for a competitive edge:

- Budgeting $5,000 to $15,000 for initial R&D can lead to sustainable practices and new products.

Tips for Minimizing Textile Recycling Expenses

- Consider purchasing used equipment or leasing to lower initial costs.

- Utilize community support and partnerships for sourcing recyclable materials.

- Focus on digital marketing strategies to reduce marketing costs.

With these textile recycling business expenses in mind, potential entrepreneurs can create a detailed budget and explore various funding options for textile recycling startups. According to industry benchmarks, the total startup costs can range from $50,000 to over $300,000 depending on the scale and operational scope. For more information on how much it costs to start a textile recycling business, you can review resources such as this [financial modeling template](https://financialmodeltemplates.com/blogs/opening/textile-recycling).

Equipment For Sorting And Processing Textiles

To successfully launch a textile recycling business like EcoThreads Recycle, investing in the right equipment for sorting and processing textiles is crucial. This investment not only affects the operational efficiency but also directly influences startup costs for textile recycling. The primary equipment needed typically includes:

- Textile sorting machines

- Shredders for fabric processing

- Balers for compacting recyclable materials

- Conveyors for material handling

- Dust collection systems for workplace safety

The costs for textile recycling equipment can vary significantly based on the scale of your operation. For instance, basic sorting machinery can start at around $10,000, while more advanced automated systems can exceed $100,000. Here’s a breakdown of potential equipment costs:

| Equipment | Estimated Cost | Purpose |

|---|---|---|

| Textile Sorting Machine | $15,000 - $100,000 | Efficiently separate materials by type and quality |

| Shredder | $5,000 - $50,000 | Process fabric into smaller pieces for recycling |

| Baler | $4,000 - $30,000 | Compact materials for transportation |

| Conveyor System | $3,000 - $20,000 | Streamline material flow within the facility |

Furthermore, considering operational costs for recycling is essential when budgeting for equipment. The longevity and maintenance of machines can add to overall expenses, which is why incorporating these factors into your textile recycling business financial plan is vital.

Tips to Minimize Equipment Costs

- Consider purchasing used or refurbished equipment to cut initial expenses.

- Negotiate with suppliers for package deals, especially if buying multiple machines.

- Explore financing options or leasing agreements which can make expensive equipment more accessible.

Prioritizing equipment based on the processing needs and volume of recyclable materials is also wise. For example, if your business focuses on a smaller local market, investing in fewer but multifunctional machines may be more cost-effective initially.

Additionally, integrating technology into your operations can enhance efficiency. Investing in software designed for inventory management and tracking can reduce human error and streamline processes, although it represents another aspect of textile recycling business expenses.

In summary, when planning your textile recycling startup, understanding the overall costs involved in sourcing and maintaining equipment is essential. By doing so, you can ensure your business remains sustainable and competitive in a rapidly evolving industry. For detailed financial modeling and budget planning, check out this resource: textile recycling financial model.

Initial Inventory of Recyclable Materials

When starting a textile recycling business like EcoThreads Recycle, one of the most significant startup costs is obtaining an initial inventory of recyclable materials. The volume and quality of textiles you can collect will directly impact your operational efficiency and profitability. It's crucial to budget adequately for this aspect of your business plan, as it accounts for a large portion of your textile recycling business costs.

Typically, the cost for initial inventory can vary widely, depending on several factors, including:

- Source of acquisition for textiles (donations, purchases from manufacturers, etc.)

- The volume of textiles needed to kickstart operations

- Transportation and logistics for acquiring the materials

For example, on average, a small textile recycling startup may require an upfront inventory of about 1,000 to 2,000 pounds of recyclable textiles. Based on local sourcing and market prices, this can cost around $0.50 to $1.50 per pound, resulting in a total initial inventory cost ranging from $500 to $3,000.

Beyond the mere cost of materials, it’s essential to consider the sustainability of the inventory sourcing process. Establishing partnerships with local fashion retailers, charities, and households can provide a steady stream of recyclables without substantial expenses. Furthermore, prioritizing quality over quantity can lead to higher value in upcycling and resale opportunities.

Tips for Sourcing Your Recyclable Inventory

- Network with local businesses and community organizations to facilitate textile donations.

- Utilize social media platforms to promote your recycling initiatives and encourage community participation.

- Implement a drop-off system or collection events to make donating easier for the public.

As you consider your initial inventory, keep in mind the operational costs for recycling which include sorting equipment and processing technology. Efficient sorting can significantly reduce overhead costs and enhance the value of the recycled materials. Investing in quality textile sorting equipment can lead to quicker processing times and better quality outputs.

Additionally, the sustainability aspect of your business can also attract funding. Many investors are interested in sustainable textile recycling initiatives that demonstrate a commitment to reducing waste. This could open up various textile business funding options, ranging from grants to eco-focused investment funds.

| Inventory Type | Average Cost per Pound | Total Estimated Cost for 2,000 lbs |

|---|---|---|

| Clothing | $1.00 | $2,000 |

| Household Textiles | $0.75 | $1,500 |

| Manufacturing Waste | $0.50 | $1,000 |

In conclusion, gaining a solid understanding of the costs associated with your initial inventory can help you formulate a realistic textile recycling business financial plan. The better you manage this expense, the more efficiently you can scale your operations in the future.

For further guidance on how to structure your finances and secure funding, consider exploring detailed resources on funding a textile recycling startup.

Facility Rental or Purchase Costs

One of the most significant startup costs for a textile recycling business is the facility rental or purchase. This expense can vary widely based on location, facility size, and the specific needs of your operation. Generally, you can expect to spend anywhere from $2,000 to $10,000 per month for rental spaces in urban areas, while smaller towns may offer more affordable options between $1,000 and $4,000 per month.

When deciding between renting and purchasing a facility, consider both the initial investment and the long-term financial implications. Purchasing a facility could involve a down payment ranging from 10-30% of the property’s value. Here are some key considerations:

- Location: Proximity to suppliers and customers can significantly impact logistics and operational costs.

- Space Requirements: The facility should accommodate storage for a recyclable textile inventory, sorting equipment, and processing machinery.

- Utilities and Maintenance: Factor in ongoing expenses such as electricity, water, and maintenance costs which can add up to 15-20% of total operational costs.

The facility layout must also be conducive to efficient operation. A well-organized space can minimize labor costs and time spent on logistics. For example, an efficient facility might need:

| Facility Type | Estimated Size (sq ft) | Monthly Rent/Purchase Price |

|---|---|---|

| Industrial Warehouse | 5,000 - 10,000 | $5,000 - $15,000 |

| Small Workshop | 1,000 - 2,000 | $1,500 - $3,500 |

| Retail + Processing Space | 2,000 - 4,000 | $2,500 - $7,000 |

While the initial costs can be daunting, there are ways to minimize these expenses:

Tips for Managing Facility Costs

- Consider shared spaces or co-op facilities to reduce rent.

- Negotiate long-term leases for better rates.

- Look into properties that may require renovation, which can offer lower purchase prices.

Additionally, as you develop your textile recycling business financial plan, take into account potential revenue streams associated with the facility, such as renting out space for recycling events or workshops related to sustainable textile practices. These strategies can help offset some of the operational costs while contributing to the community.

In summary, understanding the facility rental or purchase costs is crucial when planning how to start a textile recycling business. By carefully evaluating location, space needs, and potential operational costs, you can make informed decisions that support the sustainability goals of your business while also ensuring financial viability. For a detailed financial model that can assist in budgeting for your textile recycling startup, visit this link.

Marketing and Brand Development Expenses

Marketing plays a pivotal role in the success of a textile recycling business, especially for a startup like EcoThreads Recycle. The objective is to create awareness and engagement among eco-conscious consumers who are increasingly concerned about sustainability and textile waste. The initial startup costs for textile recycling related to marketing and brand development can include a variety of expenses:

- Branding Strategy Development: Hiring a marketing consultant or agency to assist in crafting a strong brand identity can range from $2,000 to $10,000.

- Website Development: An engaging website is crucial in today’s digital age. Depending on your needs, the costs can vary from $1,500 to $5,000 for a basic site to over $10,000 for a comprehensive e-commerce platform.

- Social Media Marketing: Budgeting for paid advertising on platforms like Facebook, Instagram, and Pinterest can range from $300 to $1,500 per month, depending on your campaign's scale.

- Content Creation: Producing quality content, including blog posts, videos, and infographics to promote sustainable practices, can cost anywhere from $500 to $3,000 annually.

- Offline Marketing: This might include flyers, brochures, and events that promote the recycling initiative, which can take about $1,000 to $5,000 depending on the scale of your initiatives.

To effectively manage these marketing and brand development expenses, it’s crucial to have a well-detailed textile recycling business financial plan. This allows you to forecast spending and set aside appropriate funds for these expenses. According to industry benchmarks, businesses typically allocate around 7-10% of their projected revenue for marketing efforts during the initial years.

Tips for Effective Marketing on a Budget

- Utilize social media platforms to promote your initiatives, as organic reach can significantly reduce costs.

- Engage in community events related to sustainability to foster partnerships and gain local visibility.

- Collaborate with influencers in the eco-friendly space for product endorsements and brand promotion at a lower cost than traditional advertising.

In addition to direct marketing expenses, consider integrating cost-effective strategies such as community outreach and educational workshops to promote sustainable textile recycling. Such initiatives not only enhance brand loyalty but also resonate with your target audience’s values. By being transparent about your upcycling processes and how EcoThreads Recycle contributes to waste reduction and sustainability, you can cultivate an engaged consumer base.

| Expense Type | Estimated Cost | Notes |

|---|---|---|

| Branding Development | $2,000 - $10,000 | Varies based on agency experience and project scope |

| Website Development | $1,500 - $10,000 | Dependent on features and e-commerce capabilities |

| Social Media Marketing | $300 - $1,500/month | Adjust based on campaign needs and audience size |

Overall, being aware of the potential textile recycling business expenses associated with marketing and brand development will better prepare you for establishing a successful venture. By investing wisely in marketing strategies that align with your brand's eco-conscious mission, you can effectively navigate the competitive landscape of the sustainable textile industry.

For detailed financial modeling to help guide your funding a textile recycling startup, consider leveraging specialized resources available at this link.

Licensing and Permitting Fees

Starting a textile recycling business like EcoThreads Recycle requires navigating a complex landscape of licenses and permits. These fees can vary significantly based on location, the scale of operations, and specific local regulations. It's crucial to understand these costs early in the planning process as they can impact the overall startup costs for textile recycling.

On average, the licensing fees for recycling businesses can range from $200 to $5,000 or more. Some of the common licenses and permits required include:

- Business License

- Environmental Permits

- Health and Safety Permits

- Waste Disposal Permits

- Local Zoning Permits

For EcoThreads Recycle, securing these licenses not only ensures legal compliance but also enhances credibility among stakeholders and customers who value sustainable practices.

| Type of License/Permit | Average Cost | Notes |

|---|---|---|

| Business License | $50 - $400 | Required for operation in your locality. |

| Environmental Permit | $1,000 - $5,000 | Varies based on the type of recycling activities. |

| Health and Safety Permit | $200 - $1,000 | Essential for employee safety and compliance. |

Additionally, understanding the permitting process can often take several months, so it’s advisable to factor this timeline into your overall textile recycling business expenses. Engaging with a legal advisor or consultant who specializes in the recycling industry can further streamline this process.

Tips for Managing Licensing Costs

- Research local regulations thoroughly to ensure compliance and avoid unexpected fees.

- Consider applying for all necessary permits simultaneously to save time and potentially reduce costs.

- Explore grant opportunities or local funding options that may assist in covering licensing and permit fees.

When strategizing for funding a textile recycling startup, it's essential to incorporate these licensing and permitting fees into your textile recycling business financial plan. Underestimating these costs could lead to budget overruns and delays in launching your venture.

By understanding the implications of licensing a textile recycling business, EcoThreads Recycle can position itself to meet compliance requirements while focusing on its core mission of promoting sustainable textile recycling. For more detailed financial planning, you might find it beneficial to explore specialized models, such as those found at Textile Recycling Financial Model.

As you embark on this journey, remember that the right approach to managing licensing and permitting fees can significantly ease the path to successful operation and growth in the recycling sector.

Insurance and Liability Coverage

Starting a textile recycling business, such as EcoThreads Recycle, involves various inherent risks, making insurance and liability coverage a critical component of your startup costs. Without proper coverage, your business could face severe financial repercussions due to unforeseen accidents, legal issues, or property damage. The right insurance not only protects your assets but also strengthens your credibility among clients and partners.

The startup costs for textile recycling often include the following insurance types:

- General Liability Insurance: This protects against claims of bodily injury or property damage. Premiums vary based on location and business size but typically range from $400 to $1,000 annually.

- Property Insurance: Covers damages to your facility and equipment due to fire, theft, or natural disasters, costing around $500 to $2,500 per year.

- Workers' Compensation Insurance: Required in most states, this covers medical expenses and lost wages for employees injured on the job. Premiums can amount to approximately $1,000 to $3,000 annually, depending on your workforce size and type of work.

- Product Liability Insurance: Essential if you plan to sell recycled products, protecting you from claims relating to defects or harm caused by your products. This could run $500 to $1,500 per year.

Based on these estimates, the total insurance costs for a textile recycling startup can range between $2,400 and $8,000 annually, significantly impacting your business's initial budget.

Tips for Reducing Insurance Costs

- Shop around for different insurers and compare quotes to find the best rates.

- Consider bundling your insurance policies for potential discounts.

- Implement safety and training programs to reduce premiums.

Having a robust insurance plan is not merely an expense but a vital strategy in minimizing long-term textile recycling business expenses. By understanding the specific insurance needs relevant to your operations and the potential risks associated with textile recycling, you can make informed decisions that contribute to the sustainability of your business.

In addition to insurance, establishing a financial plan that incorporates all aspects of your textile recycling startup, including operational costs for recycling and liabilities, is essential. By doing this, you can better allocate resources and ensure that funds are available when needed.

| Insurance Type | Estimated Annual Cost | Description |

|---|---|---|

| General Liability Insurance | $400 - $1,000 | Protects against bodily injury or property damage claims. |

| Property Insurance | $500 - $2,500 | Covers damage to facility and equipment. |

| Workers' Compensation Insurance | $1,000 - $3,000 | Covers medical expenses for employee injuries. |

| Product Liability Insurance | $500 - $1,500 | Protects against claims related to products sold. |

In summary, addressing insurance and liability coverage early in the planning stage can help mitigate risks associated with launching your textile recycling business. Proper coverage not only safeguards your investment but can also ensure smooth operations while promoting sustainable textile recycling practices.

For those looking to develop a comprehensive financial model for your textile recycling business, consider utilizing tools like the one available at Financial Model Templates, which can help you outline your expenses and secure funding effectively.

Training and Hiring Staff Costs

When embarking on a journey to establish a textile recycling business like EcoThreads Recycle, one of the significant startup costs involves training and hiring staff. This is critical to ensure that your operations run smoothly and efficiently, particularly considering the specialized tasks involved in textile sorting and processing.

The costs associated with hiring and training staff can vary widely, depending on the size of your operation, local labor market conditions, and the specific skills required for the roles. Here are some aspects to consider:

- Staff Salaries: Depending on the position, salaries for staff can range from $30,000 to $70,000 annually. Skilled positions such as textile engineers or operations managers may demand higher salaries.

- Training Programs: Implementing effective training programs is essential for a textile recycling operation. Initial training can cost around $2,000 to $5,000 per employee, including workshops, safety training, and specialized textile sorting training.

- Recruitment Costs: Hiring may involve expenses related to advertising the positions, conducting interviews, and onboarding new employees. This can add up to $1,000 to $3,000 per hire.

To give you a clearer picture, here’s a breakdown of potential staff-related expenses for a startup:

| Expense Category | Estimated Cost (Annual) | Description |

|---|---|---|

| Staff Salaries | $300,000 | For a small team of 5 employees averaging $60,000 each. |

| Training Costs | $10,000 | Including initial and ongoing training for all staff. |

| Recruitment Expenses | $5,000 | Cost incurred for hiring staff, including advertising. |

The total staffing cost in the first year can significantly impact your textile recycling business expenses, potentially reaching up to $315,000. Understanding how these costs fit into your budget is crucial for financial planning.

Tips for Minimizing Training and Hiring Costs

- Consider cross-training employees to perform multiple roles, reducing the need for additional hires.

- Utilize online training programs, which can be more cost-effective and easily scalable.

- Engage local community colleges or vocational schools for internships, which can provide skilled labor at reduced costs.

In addition to direct costs, operational considerations for your textile recycling business should also include the ongoing costs of maintaining staff morale and retention. Well-trained and motivated employees are essential for achieving your business goals.

As you refine your textile recycling business financial plan, remember to account for these staff-related expenses strategically. Efficient staffing is a cornerstone of sustainability in operations.

Finding funding for a textile recycling startup can also be explored through various resources, including grants, angel investments, or crowdfunding options specifically targeted to green initiatives. Being prepared with a solid plan can facilitate this process.

For those interested in a detailed financial model that includes staffing costs as part of your startup planning, consider checking out this resource: Textile Recycling Financial Model.

Technology and Software for Operations

Launching a textile recycling business like EcoThreads Recycle requires a strong emphasis on technology and software to streamline operations and enhance efficiency. The startup costs for textile recycling can vary significantly based on the technology you choose to implement, but investing in the right tools is essential to ensure a successful business model. The integration of advanced systems can help manage your workload, reduce operational costs, and improve recycling efficiency.

Key software and technology needs include:

- Inventory Management Systems: To efficiently track your recyclable textile inventory, having a robust system in place is crucial. This allows you to manage incoming materials, monitor stock levels, and optimize storage solutions.

- Sorting and Processing Software: Utilizing textile sorting equipment equipped with software that automates the sorting process can significantly reduce labor costs and increase accuracy in categorizing materials for recycling.

- Customer Relationship Management (CRM) Software: This helps manage communications with clients and stakeholders, fostering relationships that are vital for establishing sustainable practices and driving sales.

- Data Analytics Tools: Implementing analytics can provide insights into operational efficiency and customer behavior, allowing for informed decisions that minimize textile recycling expenses.

- Accounting and Financial Software: Essential for tracking the textile recycling business expenses, including equipment depreciation, operational costs, and revenue forecasting.

Investing in technology can also lead to a reduction in manpower and other operational costs for recycling. The right software solutions not only facilitate smoother operations but can also provide a competitive edge in the market.

Tips for Technology Integration

- Research multiple vendors to find cost-effective options for textile recycling equipment costs and software solutions.

- Consider cloud-based software to minimize upfront investment and ensure scalability.

- Stay updated on industry trends to leverage new technologies that can enhance your recycling processes.

The funding a textile recycling startup strategy should also account for these technology costs, as they can significantly influence your overall budget. On average, businesses may spend from $10,000 to $50,000 on technology solutions depending on the scale of operations and type of software selected.

| Technology Solution | Cost Range | Benefits |

|---|---|---|

| Inventory Management System | $2,000 - $10,000 | Improves material tracking and reduces waste. |

| Sorting Software | $5,000 - $30,000 | Enhances accuracy and efficiency in sorting. |

| CRM Software | $1,000 - $10,000 | Boosts customer engagement and retention. |

By carefully considering the technology and software needs of your textile recycling business, you can better manage your startup costs. This will also support a more sustainable and efficient operation, aligning perfectly with EcoThreads Recycle’s mission to address the urgent problem of textile waste.

Initial Research and Development for Upcycling Processes

Starting a textile recycling business like EcoThreads Recycle necessitates a clear focus on initial research and development (R&D) for upcycling processes. This stage is critical not only for understanding how to convert textile waste into valuable products but also for ensuring the long-term sustainability and viability of your venture. The startup costs for textile recycling often include substantial investments in R&D, as developing innovative upcycling techniques demands both labor and materials.

The textile recycling business expenses associated with R&D can typically range from $10,000 to $50,000, depending on the complexity of the processes you wish to develop. Here are some key components to consider during this crucial phase:

- Material Testing: Understanding the properties of various textiles is essential for successful upcycling. This may require purchasing samples of different materials.

- Prototype Development: Creating prototypes to test your upcycling processes can incur costs related to labor and materials.

- Laboratory Equipment: Investing in specialized equipment for testing and processing textiles may also be necessary, adding to textile recycling equipment costs.

- Consultation Fees: Engaging with industry experts to refine your upcycling strategy can ensure better outcomes but will add to your expenses.

| R&D Component | Estimated Cost | Purpose |

|---|---|---|

| Material Testing | $2,000 - $10,000 | Identifying properties of recyclable textiles |

| Prototype Development | $5,000 - $20,000 | Testing viability of upcycled products |

| Consultation Fees | $1,000 - $5,000 | Expert guidance and strategy refinement |

To ensure your innovation is effectively targeted, consider conducting market research to gauge consumer demand for various upcycled products. This can guide you in selecting the right textiles for processing and help minimize minimizing textile recycling expenses through focused R&D efforts.

Tips for Effective R&D in Upcycling

- Start small by testing low-cost textiles to validate your upcycling process.

- Collaborate with local universities or research institutions for shared resources and knowledge.

- Utilize crowdfunding or grants aimed at sustainable initiatives to ease the burden of funding a textile recycling startup.

Moreover, the incorporation of technology in your R&D process can significantly streamline operations. Investing in software that helps manage your recyclable textile inventory can save time and resources, making your upcycling initiatives more cost-effective. The textile recycling business financial plan should allocate a portion of its budget to technology needs for ensuring efficient operations.

In conclusion, placing an emphasis on R&D for upcycling processes can yield significant benefits for your textile recycling business. By understanding the key costs involved and planning effectively, businesses like EcoThreads Recycle can position themselves for success in a growing market focused on sustainability. For a detailed financial model to assist in planning your textile recycling operations, consider checking this [financial resource](https://financialmodeltemplates.com/products/textile-recycling-financial-model).