Related Blogs

In the dynamic realm of biogas production, understanding the core 7 KPI metrics is pivotal for steering your business towards success. Are you curious about how to effectively measure production efficiency, optimize operating costs, and enhance your energy output? Dive deeper into these essential metrics and discover the calculations that can transform your operations by exploring our comprehensive business plan at here.

Why Is It Important To Track KPI Metrics For A Biogas Production Business?

Tracking KPI metrics for biogas production is essential for any biogas production business, such as EcoFuel Solutions, as it enables the organization to monitor performance, optimize processes, and ensure sustainable growth. By measuring key performance indicators, businesses can effectively evaluate their operational efficiency and financial health, ultimately driving profitability and enhancing their competitive edge in the biogas industry.

In the biogas sector, the importance of KPIs cannot be overstated. These metrics help businesses identify strengths and weaknesses in their operations, thus allowing for informed decision-making. For instance, by analyzing financial KPIs for biogas, companies can assess their cost structures, revenue streams, and overall profitability. This is crucial in an industry where margins can be tight and competition fierce.

Additionally, operational KPIs for biogas play a vital role in ensuring that production processes are efficient and effective. Metrics such as biogas production efficiency and waste diversion rates are critical for understanding how well a biogas plant is performing. For example, a biogas plant with a production efficiency rate of over 90% is considered highly effective, while those below 75% may need process improvements.

Moreover, tracking these metrics allows businesses to align their operations with long-term strategic goals, such as reducing their carbon footprint or increasing energy output. For example, a targeted reduction in energy costs by 15% can significantly enhance a company's profitability while supporting broader environmental objectives.

Tips for Effective KPI Tracking

- Establish a baseline for each KPI to measure progress accurately.

- Utilize software tools to automate the collection and analysis of KPI metrics.

- Regularly review and adjust KPIs to stay aligned with business objectives and market conditions.

Lastly, the ability to track and analyze biogas efficiency metrics is invaluable for continuous improvement. Organizations that actively measure their KPIs are more likely to achieve a return on investment (ROI) of at least 20%, as they can quickly identify inefficiencies and capitalize on opportunities for growth. By staying proactive in tracking performance indicators, businesses like EcoFuel Solutions can not only optimize their operations but also contribute to a cleaner, greener planet.

What Are The Essential Financial KPIs For A Biogas Production Business?

In the biogas production business, tracking financial KPIs is essential to assess performance, manage resources effectively, and ensure profitability. For EcoFuel Solutions, understanding and calculating these metrics can offer insights into financial health, helping to navigate the emerging biogas industry efficiently.

- Revenue Per Metric Ton of Biogas: This KPI measures the income generated from each metric ton of biogas produced. By optimizing processes, businesses can aim for higher revenues, ideally exceeding $100 per metric ton based on market trends.

- Operating Costs: Understanding operating costs per unit of energy produced provides insights into efficiency. Aiming to keep operating costs below 65% of total revenues can help maintain profitability.

- Gross Margin: This KPI indicates the difference between revenue and cost of goods sold. A healthy gross margin in biogas production is often around 50%, which allows for reinvestment in facilities and technology.

- Return on Investment (ROI): Calculating ROI is crucial for measuring the profitability of investments in biogas technology. A target ROI of at least 15%-20% annually is commonly sought in this sector.

- Net Profit Margin: This metric reflects overall profitability after all expenses. For biogas companies, a net profit margin above 10% signifies a successful operational model.

- Debt-to-Equity Ratio: Maintaining a balanced debt-to-equity ratio (ideally 1:1) is important for long-term sustainability and securing financing for expansion.

- Cash Flow from Operations: Monitoring cash flow is vital for day-to-day operations, with a target of maintaining positive cash flow to ensure ongoing sustainability and growth.

Tips for Tracking Financial KPIs

- Utilize financial modeling tools to accurately track and project KPIs.

- Regularly compare your KPIs against industry benchmarks to identify improvement areas.

By focusing on these financial KPIs for biogas, EcoFuel Solutions can enhance its operational efficiency and stay competitive in the renewable energy sector. For those interested in diving deeper into profitability metrics, resources like this article provide invaluable insights.

Which Operational KPIs Are Vital For A Biogas Production Business?

For a biogas production business like EcoFuel Solutions, tracking operational KPIs is crucial to monitor efficiency, productivity, and sustainability. By focusing on the right KPI metrics for biogas production, companies can optimize their operations and make data-driven decisions. Here are some essential operational KPIs for biogas production:

- Biogas Production Efficiency: This measures how effectively organic waste is converted into biogas. A benchmark of around 70-80% conversion efficiency is considered optimal for biogas plants.

- Organic Waste Input Volume: This KPI tracks the amount of organic waste processed. As a general guideline, a biogas plant should aim to process at least 1 ton of organic material per day to remain viable.

- Energy Output From Biogas: Measuring the amount of energy produced from biogas is vital. A typical biogas plant can generate about 500-600 kWh of energy per ton of organic waste processed.

- Operating Cost Per Unit Of Energy Produced: This KPI helps evaluate cost efficiency. Ideally, the operating cost should not exceed $50 per MWh to maintain profitability.

- Waste Diversion Rate: This indicates how much waste is diverted from landfills to biogas production. A target diversion rate of 60-70% is a common benchmark in the industry.

- System Downtime Percentage: Minimizing downtime is crucial for maximizing productivity. A well-performing biogas plant should aim for less than 5% downtime annually.

- Carbon Footprint Reduction: This KPI measures the reduction of greenhouse gas emissions achieved through biogas production. A successful biogas plant can reduce emissions by approximately 50-70% compared to traditional waste disposal methods.

Tips for Tracking Operational KPIs

- Utilize automated monitoring systems to gather real-time data for accurate calculation of biogas efficiency metrics.

- Regularly review and adjust your KPIs based on operational performance and industry benchmarks to ensure continuous improvement.

By diligently tracking these operational KPIs for biogas, EcoFuel Solutions can enhance its performance, reduce costs, and contribute to a more sustainable energy future. The importance of KPIs in biogas cannot be overstated; they are a fundamental part of managing and optimizing production processes.

How Frequently Does A Biogas Production Business Review And Update Its KPIs?

In the biogas production business, particularly for a company like EcoFuel Solutions, regularly reviewing and updating KPI metrics for biogas production is crucial for maintaining operational efficiency and ensuring strategic alignment. Typically, a biogas production business should conduct KPI reviews on a quarterly basis. This frequency allows businesses to make necessary adjustments in a timely manner while minimizing disruptions.

However, certain circumstances may necessitate more frequent reviews, such as:

- Market Changes: Rapid shifts in energy pricing or regulatory frameworks can impact financial KPIs for biogas significantly.

- Operational Challenges: If unexpected downtime or inefficiencies are observed, it's essential to revisit operational KPIs for biogas immediately.

- Technological Updates: When new technologies or processes are implemented, initial performance metrics should be monitored closely until they stabilize.

Real-world statistics highlight an effective approach to KPI assessment: organizations that review their KPIs more frequently tend to see an average of 15%-30% improvement in biogas production efficiency metrics within the first year. Additionally, regular evaluations of energy output metrics for biogas can help in achieving optimized energy production, further contributing to sustainable outcomes.

Tips for Effective KPI Review

- Implement a dashboard tool for real-time tracking of biogas efficiency metrics, enabling quicker decision-making.

- Involve both operational and financial teams in the KPI review process to ensure all aspects are covered.

- Set specific targets for each KPI and assess progress relative to those goals during each review cycle.

In conclusion, the importance of KPIs in biogas cannot be overstated. Effective tracking of biogas production metrics reduces costs and drives profitability. Engaging in regular reviews not only aids in optimizing operations but also strengthens a biogas production company's ability to align its KPIs with long-term strategic goals, thereby providing a competitive edge in the renewable energy market.

What KPIs Help A Biogas Production Business Stay Competitive In Its Industry?

In the rapidly evolving biogas industry, tracking the right KPI metrics for biogas production is crucial for maintaining a competitive edge. Companies like EcoFuel Solutions must focus on core KPIs to ensure efficient operations, optimize costs, and enhance sustainability. Here are some essential KPIs that can drive competitive advantage:

- Biogas Production Efficiency: This KPI measures the volume of biogas produced per unit of organic waste input. A benchmark efficiency rate is typically around 62-75%, meaning that for every ton of organic waste, the plant should aim to produce between 700-900 cubic meters of biogas.

- Energy Output From Biogas: Monitoring energy output allows companies to assess how effectively they convert biogas into usable energy. The goal should be to achieve an output of 500 kWh for every 1,600 cubic meters of biogas produced, reflecting optimal conversion rates.

- Operating Cost Per Unit Of Energy Produced: This financial KPI helps evaluate overall profitability. Operating costs in the biogas industry can average around $80-$120 per megawatt-hour (MWh) of energy produced. Keeping these costs low is vital for competitive pricing.

- Waste Diversion Rate: As part of sustainable practices, the waste diversion rate measures the percentage of organic waste successfully converted into biogas instead of ending up in landfills. A benchmark target is to divert at least 90% of the organic waste processed.

- Customer Acquisition Cost: Understanding how much is spent to acquire each customer can impact profitability. The ideal target for this KPI should be around $50-$200 depending on market dynamics and customer retention strategies.

- Return on Investment (ROI): This financial metric is vital for assessing the profitability of investments in biogas technology and infrastructure. Aiming for an ROI of 20%-30% within the first 5 years can signify a healthy financial trajectory.

- Carbon Footprint Reduction: By measuring the amount of greenhouse gases offset through biogas production, businesses can highlight their environmental impact. Effective operations can lead to emissions reductions of up to 1,000 tons of CO2 equivalent per year.

- System Downtime Percentage: Reducing downtime is critical for maintaining continuous production. Aiming for a system downtime of less than 5% per month can maximize operational efficiency.

Tips for Calculating KPIs in Biogas Production

- Utilize software tools that can automate the tracking of biogas production metrics for easier access to real-time data.

- Regularly benchmark your operational KPIs for biogas against industry standards to ensure you're on the right path.

By effectively measuring and analyzing these biogas production business KPIs, EcoFuel Solutions can position itself as a leader in the market, driving sustainability while ensuring financial viability. For more insights on profitability and financial planning in biogas production, check out this resource.

How Does A Biogas Production Business Align Its KPIs With Long-Term Strategic Goals?

Aligning KPI metrics for biogas production with long-term strategic goals is crucial for ensuring that a biogas production business, such as EcoFuel Solutions, operates efficiently and sustainably. By integrating financial and operational KPIs for biogas, businesses can optimize their processes and make informed decisions that propel them forward. Here’s how this alignment can be achieved:

- Define Clear Objectives: Establish long-term goals, such as increasing energy output by 25% over the next five years or reducing operating costs by 15% annually. These specific targets inform which KPIs to track.

- Select Core KPIs: Choose essential core KPIs for biogas, such as biogas production efficiency, which measures the ratio of energy output to organic waste input. Other important metrics include waste diversion rate and return on investment.

- Regularly Review Progress: Schedule quarterly KPI reviews to assess whether the business is on track to meet its long-term goals. This process helps identify any adjustments needed in strategy or operations.

- Integrate KPIs into Operations: Ensure that all operational processes, from feedstock management to energy output, are designed with these KPIs in mind. For example, measure organic waste input volume directly against energy output metrics to streamline efficiency.

- Leverage Technology: Utilize software solutions for tracking biogas efficiency metrics in real-time, allowing for agile responses to any production issue or inefficiency that may arise.

Tips for Successful KPI Alignment

- Engage all stakeholders in the KPI-setting process to ensure there is a consensus on business objectives.

- Use benchmarking data from the biogas industry to set realistic targets based on the performance of leading companies.

- Continuously educate and train staff on the importance of KPI metrics for biogas production to foster a culture of data-driven decision-making.

Incorporating these practices not only facilitates the alignment of KPIs with strategic goals but also enhances the overall performance of the biogas production business, setting it up for sustainable growth and success in the industry.

What KPIs Are Essential For A Biogas Production Business’s Success?

For a biogas production business like EcoFuel Solutions, tracking the right KPI metrics for biogas production is crucial to gauge performance, optimize operations, and ensure sustainability. Here are the core KPIs that are essential for the success of your biogas production business:

- Biogas Production Efficiency: This measures the amount of biogas produced per unit of organic waste. A benchmark for efficient biogas production is around 60-70% efficiency, indicating that the majority of input resources are being converted into energy.

- Organic Waste Input Volume: Monitoring the volume of organic waste processed is vital. Aim for a target of processing over 1,000 tons of organic waste monthly to maximize energy output.

- Energy Output From Biogas: This KPI measures the amount of energy produced in relation to the biogas generated. A healthy biogas plant should output at least 500,000 kWh of energy monthly, contributing significantly to local energy grids.

- Operating Cost Per Unit Of Energy Produced: Understanding your cost structure is key. The ideal operating cost should be less than $80 per MWh produced to ensure profitability.

- Waste Diversion Rate: This KPI tracks the percentage of organic waste diverted from landfills. Target a rate of over 75% to demonstrate your commitment to sustainable waste management.

- Customer Acquisition Cost: Measuring how much it costs to acquire a new customer will help in budgeting marketing strategies. An effective target would be under $150 per customer, ensuring strong ROI.

- Return On Investment (ROI): Calculating ROI helps gauge the financial viability of biogas projects. A solid ROI benchmark is generally around 20-25%, ensuring that your investments yield meaningful returns.

- Carbon Footprint Reduction: This metric captures the decrease in greenhouse gas emissions achieved through biogas production. Aim for a reduction of at least 400 tons of CO2 annually to highlight your contribution to climate action.

- System Downtime Percentage: Keeping your operations smooth is imperative. A target of less than 5% downtime is ideal to maintain consistent production levels and financial stability.

Tips for Tracking Biogas Production Metrics

- Implement a robust data management system that can easily track and analyze these biogas production business KPIs.

- Regularly review KPIs to identify trends and areas for improvement in your biogas efficiency metrics.

Monitoring these biogas energy production metrics will empower EcoFuel Solutions to progress, remain competitive, and ultimately contribute to a more sustainable future.

Biogas Production Efficiency

One of the most crucial aspects of assessing a biogas production business is the measurement of its production efficiency. Monitoring this KPI helps businesses like EcoFuel Solutions optimize operations and achieve sustainability goals. Biogas production efficiency reflects how effectively organic waste is converted into biogas, which is essential for maximizing energy output while minimizing waste.

To quantify biogas production efficiency, businesses can utilize the following formula:

Biogas Production Efficiency (%) = (Actual Biogas Volume Produced / Potential Biogas Volume) × 100

The potential biogas volume is typically based on the organic input material’s characteristics and composition. Factors such as the type of organic waste and its degradation potential play a significant role in determining this metric.

Tips for Measuring Biogas Production Efficiency

- Conduct regular assessments of the organic waste inputs to ensure optimal degradation rates.

- Utilize advanced monitoring systems for real-time data on biogas volume produced.

- Benchmark your efficiency metrics against industry standards to identify improvement areas.

According to industry data, leading biogas production facilities achieve efficiencies of around 70% to 90%, depending on the feedstock and technology used. This translates into substantial energy outputs and reduced carbon footprints. For instance, if a facility processes 100 tons of organic waste capable of producing 500 cubic meters of biogas, monitoring its efficiency ensures the plant operates at optimal levels. An efficiency score below 70% could indicate operational issues or a need for better feedstock management.

| Input Waste Type | Potential Biogas Volume (m³) | Actual Biogas Volume Produced (m³) | Efficiency (%) |

|---|---|---|---|

| Food Waste | 800 | 630 | 78.75 |

| Agricultural Residue | 1,000 | 850 | 85.00 |

| Manure | 600 | 420 | 70.00 |

In addition to production efficiency, the KPIs for biogas production should encompass financial and operational metrics. EcoFuel Solutions can use this data to not only enhance production efficiency but also make informed decisions that align with their long-term strategic goals in the biogas industry.

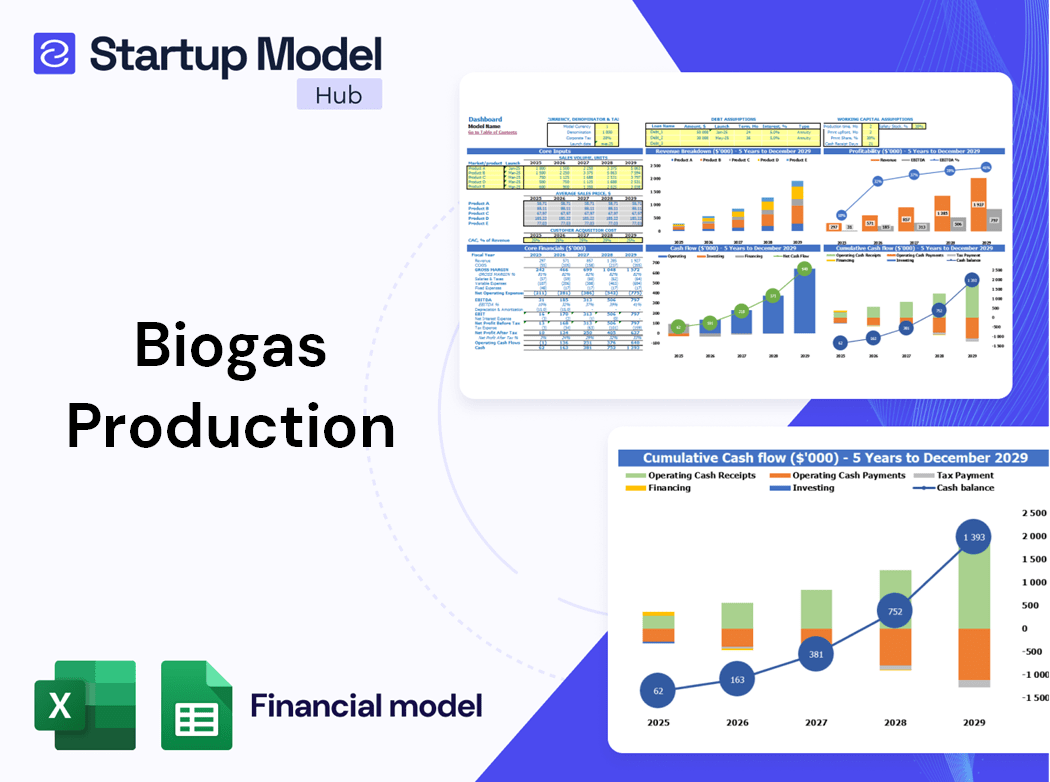

Tracking these KPI metrics for biogas production not only improves operational performance but also provides a competitive edge in the renewable energy sector. Businesses can access comprehensive financial models tailored for biogas production at this link: Biogas Production Financial Model.

Organic Waste Input Volume

The Organic Waste Input Volume is a critical KPI metric for a biogas production business, such as EcoFuel Solutions. This metric measures the total quantity of organic waste processed in a given period, directly influencing the amount of biogas produced. Efficiently managing and optimizing waste inputs not only maximizes energy output but also enhances operational efficiency, ultimately contributing to sustainability goals.

To calculate this KPI, consider the following formula:

| Parameter | Measurement Unit | Calculation Method |

|---|---|---|

| Total Organic Waste | Tonnes | Sum of all organic waste inputs over the period |

| Input Frequency | Days | Total days the plant operated in the period |

| Average Daily Input | Tonnes/Day | Total Organic Waste / Input Frequency |

For example, if EcoFuel Solutions processes 500 tonnes of organic waste in a month (30 days), the average daily input would be:

Average Daily Input = 500 tonnes / 30 days = 16.67 tonnes/day

Tracking the Organic Waste Input Volume allows biogas production facilities to:

- Identify trends in waste availability and adjust procurement strategies accordingly.

- Optimize biogas production cycles by ensuring consistent input levels without overloading the system.

- Enhance partnerships with local waste generators for reliable waste sources.

- Monitor seasonal variations in organic waste supply, which is crucial for planning.

Tips for Maximizing Organic Waste Input

- Establish relationships with local farms, restaurants, and food distributors to secure organic waste.

- Implement a waste tracking system to accurately measure incoming waste volumes.

- Regularly evaluate the types of organic waste being collected and processed for efficiency in biogas production.

In the context of operational KPIs for biogas, maintaining a robust record of organic waste input not only supports efficient production processes but also enhances the renewable energy output metrics. According to industry reports, a biogas plant can achieve energy outputs of 300 to 600 m³ of biogas per tonne of organic waste processed, illustrating the profound impact of this KPI on overall plant performance.

By consistently measuring the Organic Waste Input Volume, EcoFuel Solutions will be able to drive improvements, enhance resource utilization, and contribute to a more sustainable energy framework, ensuring a competitive edge in the rapidly evolving biogas industry. For those interested in a comprehensive financial model tailored for the biogas production business, consider exploring options at this link.

Energy Output From Biogas

Measuring the energy output from biogas is one of the most critical KPI metrics for biogas production. This metric not only reflects the efficiency of the biogas production process but also plays a significant role in determining the economic viability of a biogas production business like EcoFuel Solutions. Understanding how to calculate this KPI is essential for maximizing energy yield and optimizing operations.

The energy output from biogas can be quantified in terms of megawatt-hours (MWh) or kilowatt-hours (kWh) generated from the biogas produced. This is typically calculated using the following formula:

| Component | Details | Formula |

|---|---|---|

| Biogas Production | Measure the total volume of biogas produced (in m³). | Volume of biogas (m³) x Energy content of biogas (kWh/m³) |

| Energy Output | Convert the total biogas volume into total energy output. | Total energy output (kWh) = Total biogas produced (m³) x Energy content (kWh/m³) |

The average energy content of biogas is approximately 5.5 kWh/m³. Therefore, if your biogas plant produces 1,000 m³ of biogas, the energy output can be calculated as:

Energy Output = 1,000 m³ x 5.5 kWh/m³ = 5,500 kWh

Regularly tracking this energy output metric allows businesses to:

- Assess overall biogas efficiency and productivity.

- Identify trends over time and optimize operational parameters.

- Make informed decisions regarding technology upgrades and investment in renewables.

Tips for Maximizing Energy Output

- Conduct routine maintenance checks on biogas systems to ensure optimal performance.

- Invest in technologies that enhance biogas yield, such as anaerobic digesters with higher efficiency ratings.

- Analyze organic waste inputs regularly to ensure ideal feedstock for maximum output.

A strong focus on energy output from biogas will enhance the ability of EcoFuel Solutions to address community waste management needs while promoting sustainable energy solutions. By effectively measuring and tracking this vital operational KPI for biogas production, businesses can capitalize on opportunities, leading to a more sustainable future.

Operating Cost Per Unit Of Energy Produced

In the biogas production business, the operating cost per unit of energy produced is a crucial KPI that directly impacts profitability and sustainability. This metric gauges the overall efficiency of the biogas operation by indicating how much it costs to generate a specific unit of energy, typically measured in megawatt-hours (MWh). By minimizing this cost, EcoFuel Solutions can enhance its competitive edge while fulfilling its mission of transforming organic waste into renewable energy.

The calculation of this KPI involves the following formula:

Operating Cost Per Unit Of Energy Produced = Total Operating Costs / Total Energy Output (MWh)

For example, if EcoFuel Solutions incurs total operating costs of $200,000 and produces 1,000 MWh of energy, the operating cost per unit would be:

$200,000 / 1,000 MWh = $200 per MWh

Regular analysis of this KPI can help identify areas of waste and inefficiency. Factors affecting this cost may include:

- Raw material costs (e.g., organic waste inputs)

- Labor costs associated with operations and maintenance

- Energy expenses tied to the production process

- Depreciation and amortization of biogas plant assets

- Utility costs related to energy consumption

Tips for Reducing Operating Costs

- Conduct regular audits of resource utilization to identify inefficiencies.

- Invest in technology to enhance biogas production efficiency metrics.

- Evaluate supplier contracts for organic waste to potentially reduce input costs.

- Implement maintenance schedules to minimize system downtime percentage.

Benchmarking against industry standards can also provide valuable insights. According to recent studies, the average operating cost per unit in the biogas industry ranges from $60 to $120 per MWh, depending on the scale of production and technological advancements used. By strategically targeting to lower its operating cost below these benchmarks, EcoFuel Solutions can position itself favorably in the renewable energy market.

| EcoFuel Solutions | Industry Average | |

|---|---|---|

| Total Operating Costs | $200,000 | $150,000 |

| Total Energy Output (MWh) | 1,000 | 1,500 |

| Operating Cost Per MWh | $200 | $100 |

By tracking and optimizing the operating cost per unit of energy produced, EcoFuel Solutions can not only increase its profitability but also contribute significantly to the sustainability goals of the biogas production sector. This focus on cost efficiency will be vital in enhancing the overall performance metrics of the biogas production business.

For more information on how to effectively analyze and improve your operational KPIs, consider utilizing specialized tools and financial models designed specifically for the biogas industry, such as those available at Financial Model Templates.

Waste Diversion Rate

The waste diversion rate is a critical KPI metric for biogas production businesses like EcoFuel Solutions. It measures the percentage of organic waste that is successfully diverted from landfills and converted into biogas, playing a crucial role in both environmental sustainability and the overall efficiency of the biogas production process.

Calculating the waste diversion rate involves the following formula:

Waste Diversion Rate (%) = (Organically Diverted Waste / Total Waste Generated) x 100

For instance, if EcoFuel Solutions processes 50,000 tons of organic waste annually and successfully diverts 40,000 tons into biogas production, the waste diversion rate would be:

Waste Diversion Rate = (40,000 / 50,000) x 100 = 80%

An 80% diversion rate signifies a robust operational capacity, helping to emphasize the company's role in enhancing waste management strategies. High waste diversion rates not only affirm compliance with environmental regulations but also enhance the company's reputation in sustainable practices.

Tracking waste diversion rates allows EcoFuel Solutions to identify areas for improvement and optimize operational KPIs for biogas production. By continuously monitoring this metric, the company can adjust its waste processing techniques to maximize efficiency and sustainability.

Tips for Improving Waste Diversion Rate

- Implement source separation programs to better segregate organic waste at the point of generation.

- Engage with local businesses and communities to promote the benefits of diverting waste for biogas production.

- Invest in advanced waste processing technologies that improve the efficiency of organic waste conversion.

To benchmark performance, the waste diversion rates in the biogas industry typically range from 50% to 85%, depending on the operational efficiencies and technology used. Maintaining a diversion rate above 70% is generally considered exemplary, positioning EcoFuel Solutions as a leader in the biogas sector.

| Waste Diversion Rate Category | Percentage Range | Interpretation |

|---|---|---|

| Excellent | Above 70% | Industry leader with sustainable practices |

| Good | 50% - 70% | Competitively sustainable |

| Needs Improvement | Below 50% | Potential compliance issues |

As EcoFuel Solutions strives to improve its waste diversion rate, aligning this KPI with long-term strategic goals of sustainability and community engagement will further reinforce the company's position as a responsible biogas production leader.

In addition, integrating waste diversion metrics with other operational KPIs can help to track biogas production metrics comprehensively. This holistic view allows businesses to create actionable strategies that not only improve efficiency but also reduce the overall environmental impact.

For a deeper dive into calculating and tracking these essential KPIs for biogas production success, consider exploring financial models tailored for the biogas industry at EcoFuel Solutions Financial Model.

Customer Acquisition Cost

In the biogas production business, particularly for EcoFuel Solutions, understanding Customer Acquisition Cost (CAC) is vital for sustaining a competitive edge. CAC refers to the total cost associated with acquiring a new customer, which includes marketing expenses, sales team expenditures, and any other costs incurred during the acquisition process. This metric is crucial for evaluating the effectiveness of marketing strategies and overall business profitability.

To calculate CAC, one can use the following formula:

CAC = Total Marketing and Sales Costs / Number of New Customers Acquired

For example, if EcoFuel Solutions spends $100,000 on marketing and sales efforts in a given period and acquires 200 new customers, the CAC would be:

CAC = $100,000 / 200 = $500

This indicates that it costs the business $500 to gain each new customer. Tracking this metric over time helps in evaluating the effectiveness of marketing strategies and adjusting them to optimize customer acquisition.

| Year | Total Costs ($) | New Customers Acquired | CAC ($) |

|---|---|---|---|

| 2021 | 100,000 | 200 | 500 |

| 2022 | 120,000 | 300 | 400 |

| 2023 | 150,000 | 350 | 428.57 |

Monitoring CAC is essential as it provides insights into customer lifetime value (CLV) in comparison with acquisition costs. The ideal scenario is to have a CLV that significantly exceeds CAC, resulting in a sustainable business model.

Tips for Reducing Customer Acquisition Cost

- Utilize digital marketing platforms effectively to reach a broader audience at a lower cost.

- Enhance customer referral programs to incentivize existing customers to bring new clients.

- Focus on content marketing to attract organic traffic and reduce reliance on paid advertising.

In the competitive biogas industry, understanding and optimizing CAC can lead to enhanced profitability and growth. By continuously analyzing the effectiveness of marketing campaigns and adjusting strategies accordingly, EcoFuel Solutions can maintain a strong foothold in the market. The importance of tracking KPI metrics for biogas production cannot be overstated, as it drives informed decision-making that ultimately affects the bottom line.

For more insights on financial modeling and KPI calculations for a biogas production business, visit this link.

Return On Investment

Return on Investment (ROI) is a critical financial KPI for biogas production businesses like EcoFuel Solutions. It measures the profitability of an investment and is essential for understanding how effectively resources are being utilized to generate returns. In the biogas industry, where capital investments can be substantial, calculating ROI provides insights into whether the business is on the right track toward achieving sustainable growth and profitability.

To calculate ROI for a biogas production business, the formula is straightforward:

ROI = (Net Profit / Cost of Investment) x 100

Where:

- Net Profit is the total revenue from biogas sales minus all associated operational costs (e.g., maintenance, labor, and overhead).

- Cost of Investment includes initial setup costs, equipment purchases, and any ongoing expenses directly related to the production process.

For instance, if EcoFuel Solutions invests $1,000,000 in establishing a biogas plant and generates $1,200,000 in revenue with operational costs of $800,000 in the first year, the calculation would be:

| Item | Amount ($) |

|---|---|

| Revenue | 1,200,000 |

| Operational Costs | (800,000) |

| Net Profit | 400,000 |

| Investment Costs | 1,000,000 |

| ROI Calculation | (400,000 / 1,000,000) x 100 = 40% |

This means that EcoFuel Solutions would achieve a 40% ROI from its biogas production operations, indicating a healthy return relative to its investment. Generally, a ROI of >15% is considered attractive in the renewable energy sector.

Tips for Improving ROI in Biogas Production

- Conduct regular audits on operational costs to identify areas for efficiency improvements.

- Explore alternative revenue streams such as selling by-products (e.g., fertilizer from digestate).

- Invest in technology upgrades that enhance energy output or reduce downtime.

Monitoring ROI is vital for maintaining competitiveness in the biogas industry. It allows EcoFuel Solutions to adjust strategies proactively, ensuring sustainable growth and a strong financial position. As the business scales, continual tracking of ROI coupled with other core KPIs for biogas can significantly enhance decision-making and strategic planning.

Understanding the importance of ROI in conjunction with other financial KPIs for biogas production can help businesses align their investments with long-term strategic goals. By leveraging accurate calculations and regular assessments, EcoFuel Solutions can make informed decisions that bolster its position in the market.

Carbon Footprint Reduction

One of the most significant benefits of a biogas production business, such as EcoFuel Solutions, is its potential to contribute to substantial carbon footprint reduction. By transforming organic waste into renewable energy, biogas production plays a vital role in mitigating greenhouse gas emissions.

When organic waste decomposes anaerobically (without oxygen), it generates methane, a potent greenhouse gas. Instead of allowing this methane to escape into the atmosphere, biogas production captures it, converts it to energy, and reduces reliance on fossil fuels. This process can lead to a carbon footprint reduction of up to 60-70% compared to conventional waste management practices.

To effectively measure the carbon footprint metrics in your biogas production operations, consider tracking the following KPIs:

- Carbon offset per unit of biogas produced: Calculate the amount of CO2 emissions prevented by capturing methane from organic waste.

- Reduction in carbon emissions from fossil fuel substitution: Assess the decrease in CO2 emissions by quantifying the energy produced through biogas that replaces fossil fuels.

- Organic waste treated: The total volume or weight of organic waste processed can also provide insight into the potential reductions achievable.

According to industry benchmarks, a typical biogas plant can reduce CO2 emissions by approximately 2,500 to 5,000 metric tons annually, depending on the scale of operations and the types of waste processed. This not only enhances sustainability but also strengthens your position in the ever-evolving renewable energy marketplace.

Tips for Maximizing Carbon Footprint Reduction

- Conduct regular audits of your biogas production processes to identify areas for improvement in reducing emissions.

- Invest in technologies that enhance biogas capture efficiency, such as improved digesters or gas storage systems.

- Engage with local communities to promote organic waste recycling initiatives, increasing waste inputs into your biogas production and, consequently, carbon offset capabilities.

On a financial note, understanding your carbon footprint reduction not only enhances your environmental impact but also can lead to considerable economic benefits. Many regions offer subsidies and tax incentives for renewable energy initiatives that demonstrate significant reductions in greenhouse emissions. For example, governmental programs can provide up to 30% funding for projects that achieve predetermined environmental goals.

By tracking these KPIs for biogas production, you can align your operational strategies with broader environmental objectives, making your biogas production business not only viable but also an essential contributor to a sustainable future.

| Metric | Estimated Carbon Reduction (metric tons/year) | Potential Subsidy (% of project cost) |

|---|---|---|

| Small Scale Plant (100kW) | 2,500 | 30% |

| Medium Scale Plant (500kW) | 5,000 | 30% |

| Large Scale Plant (1MW) | 10,000 | 25% |

As the biogas industry evolves, maintaining a focus on your carbon footprint metrics will not only allow your business to track its environmental impact but can also enhance your brand reputation, leading to greater customer loyalty and potential competitive advantages in the market.

System Downtime Percentage

In the biogas production business, particularly for companies like EcoFuel Solutions, tracking the System Downtime Percentage is crucial for maintaining operational efficiency and profitability. This KPI measures the amount of time a biogas production system is not operational compared to the total available production time. A high downtime percentage can indicate equipment failures, maintenance issues, or operational inefficiencies, all of which can severely impact overall production and profitability.

To calculate the System Downtime Percentage, use the following formula:

System Downtime Percentage (%) = (Total Downtime / Total Available Production Time) x 100

For instance, if a biogas plant experiences 10 hours of downtime in a week where the total available production time is 168 hours, the calculation would be:

System Downtime Percentage = (10 / 168) x 100 = 5.95%

In industry benchmarks, a System Downtime Percentage of less than 5% is considered excellent, while 10% to 15% percent is generally acceptable for many operational settings. Anything above this threshold could indicate potential issues requiring immediate attention.

| Benchmark Category | Percentage Range | Comments |

|---|---|---|

| Excellent Performance | 0% - 5% | Indicates high efficiency and minimal downtime. |

| Acceptable Performance | 6% - 10% | Room for improvement; may require maintenance review. |

| Poor Performance | 11% and above | Immediate action required to address operational issues. |

Minimizing downtime is essential for maximizing productivity and costs per unit of energy produced. Regular maintenance schedules, staff training, and efficient resource planning can significantly help in reducing downtime.

Tips to Reduce System Downtime

- Implement a proactive maintenance schedule to prevent unexpected failures.

- Invest in training programs for staff to improve operational efficiency.

- Utilize real-time monitoring systems to quickly identify and address issues.

By focusing on the System Downtime Percentage, EcoFuel Solutions can align its operational goals with financial performance, ensuring sustainability and competitive advantage within the biogas industry. Tracking KPIs in biogas production not only aids in operational efficiency but also helps in making informed decisions that positively impact the bottom line. For detailed financial modeling and projections, consider checking out this biogas production financial model.