Related Blogs

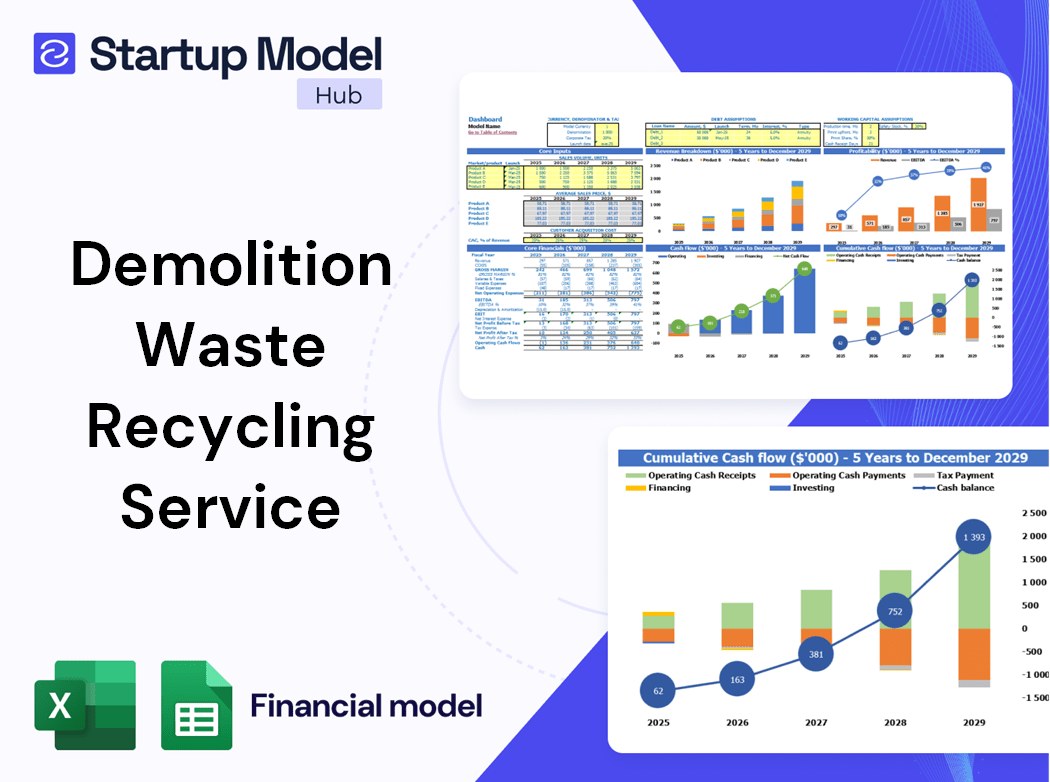

Are you aware of the core 7 KPI metrics that can significantly boost your demolition waste recycling service business? Understanding and tracking these essential metrics not only helps in streamlining operations but also enhances profitability. Ready to dive deeper into how to calculate these vital KPIs? Explore this comprehensive guide and empower your business strategy today: Demolition Waste Recycling Service Financial Model.

Why Do You Need To Track KPI Metrics For Demolition Waste Recycling Service Business?

Tracking KPI metrics for demolition waste recycling is essential for ensuring the effectiveness and sustainability of your business model. By diligently measuring and analyzing these key performance indicators (KPIs), you can gain valuable insights into various aspects of your operations, financial health, and overall business performance.

For a company like EcoDemolish Solutions, which focuses on revolutionizing the demolition waste management industry, understanding these metrics can lead to improved decision-making and operational efficiency. Here are several reasons why tracking KPIs is crucial:

- Performance Measurement: By utilizing waste recycling performance metrics, you can effectively monitor your demolition project efficiency, ensuring that resources are being utilized optimally and waste is minimized.

- Cost Management: Implementing recycling cost analysis metrics can identify unnecessary expenses, allowing you to refine your approaches and drive down costs while maintaining quality.

- Sustainability Goals: KPI metrics help assess your progress towards sustainability KPIs for recycling, such as the percentage of waste diverted from landfills, enhancing your company’s environmental impact.

- Client Satisfaction: Understanding your customer satisfaction in waste services through KPIs like the Client Satisfaction Score can inform improvements in service delivery and client engagement.

- Competitive Analysis: Monitoring competitive KPIs in demolition industry allows you to benchmark against industry standards and identify areas for improvement, providing a strategic advantage.

Moreover, regular KPI reviews can help you remain adaptable in a constantly evolving market. A recent study indicated that companies actively tracking their KPIs experience a 20% increase in operational efficiency compared to those that do not.

Tips for Effective KPI Tracking

- Set specific targets for each KPI to create clear performance expectations.

- Utilize software tools for real-time data collection and analysis to streamline the KPI calculation for recycling business.

- Engage employees in the KPI tracking process to foster a culture of accountability and performance awareness.

As you refine your approach to measure demolition waste performance, remember that these KPIs can also guide long-term strategic planning, aligning operational objectives with overarching business goals.

What Are The Essential Financial KPIs For Demolition Waste Recycling Service Business?

In the demolition waste recycling service sector, tracking financial KPIs is crucial for understanding the economic health and efficiency of operations. For a business like EcoDemolish Solutions, these financial KPIs serve as benchmarks to measure success, optimize resource allocation, and enhance profitability.

- Revenue Growth Rate: This metric measures the increase in revenue over specific periods, usually calculated quarterly or annually. A healthy growth rate indicates that the business is expanding its client base and service reach. For instance, an annual growth rate of over 10% is often considered robust in the recycling industry.

- Cost Per Ton of Recycled Material: This KPI reflects the operational efficiency and cost-effectiveness of recycling processes. It can be calculated by dividing the total operational costs by the total tons of materials recycled. The goal is to maintain or reduce this cost over time, ideally under $50 per ton.

- Percentage of Waste Diverted from Landfills: A critical measure of sustainability, this KPI calculates the proportion of waste successfully recycled versus what ends up in landfills. A top-performing recycling service should aim for at least 75% diversion.

- Operational Efficiency Ratio: This KPI assesses the relationship between output and input costs. A lower ratio indicates higher efficiency, with a target ratio ideally below 0.5.

- Gross Margin: This financial metric represents the percentage of revenue that exceeds the cost of goods sold (COGS). A gross margin of 30% or higher is often sought in service industries.

The effectiveness of these financial KPIs depends on their frequency of review. Regular analysis, perhaps quarterly, allows businesses to identify trends and adjust their strategies accordingly. This aligns with the suggestion to implement systematic KPI reviews in the demolition waste recycling industry for enhanced performance.

Tips for Calculating Financial KPIs

- Utilize software tools for accurate KPI tracking; estimates can often lead to misleading conclusions.

- Regularly benchmark your KPIs against industry standards to measure performance effectively.

- Consider integrating client feedback into your revenue growth strategies to bolster financial outcomes.

For more insights on financial performance metrics for your demolition waste recycling service, check out resources on profitability. Understanding these financial KPIs is essential for ensuring long-term sustainability and growth in the competitive landscape of waste management.

Which Operational KPIs Are Vital For Demolition Waste Recycling Service Business?

Operational KPIs for demolition waste recycling businesses are essential for assessing performance, ensuring efficiency, and measuring sustainability efforts. For a company like EcoDemolish Solutions, focusing on effective KPIs helps to drive eco-conscious practices while providing significant cost savings to clients.

Here are some core operational KPIs that are vital for measuring demolition waste performance:

- Recycling Rate: This metric shows the percentage of demolition waste that is successfully recycled. To calculate it, divide the total amount of recycled materials by the total amount of waste generated, then multiply by 100. For instance, if 800 tons out of 1,000 tons of waste are recycled, the recycling rate is 80%.

- Average Turnaround Time for Recycling Projects: This measures the average time taken to complete recycling projects. Tracking this metric helps identify bottlenecks and improve efficiency. For example, aiming for a turnaround time of less than 10 days can offer competitive advantages.

- Material Recovery Rate: This KPI indicates the efficiency of material recovery processes. It is calculated by dividing the weight of materials recovered by the total weight of materials processed. A high recovery rate, ideally above 75%, reflects effective recycling operations.

- Percentage of Waste Diverted from Landfills: To measure sustainability efforts, it’s crucial to track how much waste is diverted from landfills. Divide the waste diverted by the total waste generated and multiply by 100. A target of 90% diversion is commendable in the industry.

- Employee Training Compliance Rate: This metric gauges how well employees are trained in operational procedures and safety protocols related to recycling. A compliance rate of 100% indicates all employees are trained in best practices for waste management.

- Operational Efficiency Ratio: This KPI assesses the relationship between outputs and inputs in the recycling process. It can be calculated by dividing the total outputs (recycled materials) by total costs. A higher ratio signifies greater operational efficiency.

Tips for Improving Operational KPIs

- Regularly assess and adjust processes to reduce the average turnaround time for projects.

- Invest in employee training programs to achieve high compliance rates and promote best practices.

- Implement technology solutions for tracking waste and enhancing material recovery rates.

Understanding and tracking these operational KPIs not only enhances performance but also reinforces EcoDemolish Solutions’ commitment to sustainability and resource recovery in the demolition waste recycling industry. Regular KPI reviews and adjustments are necessary to stay ahead in this competitive market. For more insights, consider reading articles on opening a demolition waste recycling service.

How Frequently Does Demolition Waste Recycling Service Business Review And Update Its KPIs?

In the dynamic landscape of the demolition waste recycling industry, establishing and maintaining effective KPI metrics is essential for measuring performance and ensuring sustainability. The frequency at which demolition waste recycling KPIs are reviewed and updated can significantly influence the overall operational effectiveness and financial health of the business.

Typically, businesses like EcoDemolish Solutions should consider a structured approach to KPI review. It is recommended that KPIs be assessed on a monthly basis to allow for timely adjustments and optimizations. This routine facilitates swift responses to operational challenges and market changes. Additionally, a more thorough review should occur on a quarterly basis to evaluate progress against strategic goals.

In determining the frequency of KPI reviews, businesses should take into account the following factors:

- Regulatory Changes: The demolition and waste management industry is affected by evolving regulations, which may necessitate changes to the KPIs tracked.

- Market Trends: Shifts in market demand for recycled materials can impact the relevance of specific KPIs; regular updates help maintain competitiveness.

- Operational Changes: New technologies or processes implemented in waste management may require reevaluation of current KPIs to ensure they align with operational efficiency.

- Feedback from Stakeholders: Regular collection of feedback from clients and employees about operational and sustainability objectives can inform necessary adjustments to KPIs.

Moreover, companies should leverage real-time data analytics tools for continuous monitoring of waste recycling performance metrics. This enables agile responses to issues like tracking the percentage of recycled materials and adjusting strategies accordingly. For example, if the average turnaround time for recycling projects starts to lengthen, immediate review of related KPIs is essential.

Strategies for Effective KPI Review

- Implement automated tracking systems to streamline data collection and analysis, reducing manual errors.

- Engage in regular training sessions for staff to ensure they understand the importance of KPIs and their impact on business goals.

- Incorporate client satisfaction metrics to ensure service quality aligns with market expectations.

Ultimately, the commitment to regular KPI evaluations enables EcoDemolish Solutions to enhance sustainability practices, increase client satisfaction, and achieve significant cost savings. For additional insights on this subject, consider reviewing financial performance benchmarks that can further guide KPI adjustments.

What KPIs Help Demolition Waste Recycling Service Business Stay Competitive In Its Industry?

In the competitive landscape of the demolition waste recycling service industry, identifying and measuring the right KPI metrics for demolition waste recycling is crucial for sustaining operational efficiency and strategic growth. These metrics not only provide insights into current performance but also help EcoDemolish Solutions maintain its position as a market leader in eco-conscious practices.

Key performance indicators (KPIs) serve as benchmarks that allow businesses to gauge their success against industry standards. The following KPIs are essential for staying competitive:

- Recycling Rate: This metric indicates the percentage of materials recycled from total demolition waste. An industry average reflects a recycling rate of 60% to 80% depending on the types of materials processed.

- Percentage of Waste Diverted from Landfills: A higher percentage signifies more efficient waste management practices. Aim for a target of at least 75% waste diversion to stay competitive.

- Cost Per Ton of Recycled Material: Understanding the costs associated with recycling operations helps in pricing strategies and cost management. Keeping this cost below $100 per ton can provide a competitive advantage.

- Client Satisfaction Score: This metric directly affects repeat business. Aiming for a client satisfaction score above 85% is vital for securing long-term contracts.

- Operational Efficiency Ratio: This KPI measures the ratio of outputs to inputs, helping to assess how effectively resources are utilized. A ratio above 1.2 indicates efficient operations.

- Material Recovery Rate: This reflects the efficiency of material recovery processes. Aim to achieve a recovery rate of at least 90% to ensure maximum resource recovery.

- Average Turnaround Time for Recycling Projects: Establish benchmarks for project completion times, with an average between 5 to 10 days for recycling projects being ideal in maintaining client trust.

Tips for Monitoring Your KPIs

- Regularly review and update your KPIs to align with changing business goals and industry trends.

- Implement digital tracking tools for real-time reporting of KPI metrics for demolition waste recycling.

- Engage your team in discussions around KPI achievements to foster a culture of accountability and continuous improvement.

By closely monitoring these competitive KPIs in the demolition industry, EcoDemolish Solutions can enhance its operational strategies and maintain a leading edge in the market. This proactive approach to measuring demolition waste performance ensures that the company is not just meeting industry standards but exceeding them, ultimately driving further growth and sustainability.

How Does Demolition Waste Recycling Service Business Align Its KPIs With Long-Term Strategic Goals?

Aligning KPI metrics for demolition waste recycling with long-term strategic goals is crucial for business success, especially for a company like EcoDemolish Solutions. The focus on sustainability and resource recovery not only boosts operational efficiency but also enhances competitiveness in a rapidly evolving industry. By implementing effective KPI calculations for the recycling business, EcoDemolish Solutions can strategically position itself to capitalize on market trends.

The first step in aligning KPIs with strategic goals is to clearly define those goals. For EcoDemolish Solutions, some core goals may include:

- Improving recycling rates and sustainability performance metrics.

- Enhancing client satisfaction through efficient service delivery.

- Minimizing operational costs while maximizing recovery efficiencies.

To achieve these goals, EcoDemolish Solutions tracks a variety of demolition waste recycling KPIs, including:

- Recycling Rate: Aiming for a target of over 80% to enhance eco-friendliness.

- Cost Per Ton of Recycled Material: Aiming to reduce this metric by 15% over the next three years.

- Percentage of Waste Diverted from Landfills: Striving for a diversion rate of 90%.

- Average Turnaround Time for Recycling Projects: Reducing the average time to 48 hours.

Regular assessments of these KPIs contribute to operational efficiencies, highlighting areas needing improvement while providing data to support strategic decision-making. Additionally, conducting a KPI review frequency in recycling every quarter allows EcoDemolish Solutions to stay adaptive to changing market conditions and operational challenges.

Tips for Aligning KPIs with Strategic Goals:

- Ensure KPIs are Specific, Measurable, Achievable, Relevant, and Time-bound (SMART).

- Incorporate feedback from clients and employees to refine your metrics.

- Use software tools for real-time KPI tracking and analysis.

- Benchmark against industry standards to gauge performance.

Ultimately, by aligning core KPIs for recycling services with its long-term strategic goals, EcoDemolish Solutions can significantly enhance its operational performance. This alignment not only ensures that the business is on track to meet its sustainability objectives but also prepares it to face emerging challenges in the demolition waste management landscape.

What KPIs Are Essential For Demolition Waste Recycling Service Business’s Success?

In the rapidly evolving landscape of the demolition waste recycling industry, tracking KPI metrics for demolition waste recycling is crucial for ensuring operational efficiency, sustainability, and financial viability. For

Key KPIs essential for the success of a demolition waste recycling service include:

- Recycling Rate: This metric indicates the percentage of total waste recycled compared to the waste collected. A higher recycling rate reflects greater efficiency and effective waste management practices. Aim for a recycling rate of over 60% to align with industry standards.

- Cost Per Ton Of Recycled Material: Evaluating the recycling cost analysis metrics reveals how much it costs to recycle a ton of waste. This should ideally be under $50 per ton, helping to maintain competitive pricing.

- Percentage Of Waste Diverted From Landfills: This KPI measures the effectiveness of your recycling efforts in reducing landfill dependency, with an industry benchmark set at 70% diversion.

- Average Turnaround Time For Recycling Projects: Tracking the average recycling turnaround time allows businesses to improve efficiency. Keeping this under 10 days can enhance client satisfaction.

- Client Satisfaction Score: Regularly measuring customer satisfaction helps identify areas for improvement. Aim for a score of at least 85% to ensure repeat business and referrals.

- Revenue Growth Rate: Measure the year-over-year revenue growth rate to assess financial health. A target growth rate of 15% annually can indicate successful market positioning.

- Operational Efficiency Ratio: This ratio assesses the efficiency of resource utilization in recycling operations. A ratio above 80% is considered indicative of a well-performing recycling service.

- Material Recovery Rate: Tracking the amount of recoverable material versus total waste processed is essential. A recovery rate of 50% or more is often expected in the industry.

- Employee Training Compliance Rate: This KPI signifies the percentage of employees who have completed required training. A compliance rate of at least 90% ensures a knowledgeable workforce dedicated to best practices in recycling.

Tips for KPI Implementation

- Regularly review and analyze your KPIs to identify trends and areas for improvement.

- Implement software solutions for real-time tracking of KPIs to enhance decision-making.

- Engage employees in understanding how their roles impact key performance metrics, promoting a culture of accountability.

By effectively measuring these demolition waste recycling KPIs,

Recycling Rate

The recycling rate is a critical KPI metric for demolition waste recycling services. It represents the percentage of waste materials collected from demolition projects that are successfully processed and transformed into reusable resources. For a business like EcoDemolish Solutions, tracking this metric is essential for measuring demolition waste performance, enhancing operational efficiency, and promoting sustainability.

Calculating the recycling rate involves a straightforward formula:

Recycling Rate (%) = (Total Recycled Material / Total Waste Collected) × 100

To illustrate, if EcoDemolish Solutions collected 1,000 tons of demolition waste and successfully recycled 600 tons, the recycling rate would be:

Recycling Rate = (600 tons / 1,000 tons) × 100 = 60%

This recycling rate not only highlights the organization's commitment to eco-friendly practices but also serves as a benchmark against industry standards. For instance, the average recycling rate in the demolition industry hovers around 50% - 70%, depending on the region and type of materials involved.

| KPI Metric | Industry Benchmark | EcoDemolish Solutions Goal |

| Recycling Rate | 50% - 70% | 80% |

| Cost Per Ton of Recycled Material | $50 - $100 | $45 |

| Client Satisfaction Score | 80%+ | 90% |

In addition to the quantitative aspect, the recycling rate also plays a role in influencing client decisions. A higher recycling rate can improve customer satisfaction in waste services, as clients increasingly prioritize sustainability in their projects. By effectively communicating their recycling rates, EcoDemolish Solutions can strengthen its market position and attract environmentally-conscious clients.

Tips for Improving Recycling Rate

- Conduct regular audits of recycling processes to identify areas for improvement.

- Invest in advanced recycling technologies and equipment to enhance material recovery.

- Provide training to employees on best practices for maximizing recycling during demolition projects.

- Establish partnerships with local recycling facilities to streamline material processing.

Furthermore, tracking the recycling rate provides actionable insights for the business in terms of operational KPIs for waste management. By measuring trends in recycling rates, EcoDemolish Solutions can adjust its strategies to align with its long-term strategic goals and ensure compliance with evolving regulations concerning demolition waste management.

In summary, the recycling rate not only reflects the efficiency of EcoDemolish Solutions in managing demolition waste but also plays an integral role in promoting sustainability within the industry. By striving to enhance this core KPI, the business can solidify its leadership position and reinforce its commitment to responsible waste recycling practices. For a comprehensive approach to financial viability, consider exploring the demolition waste recycling service financial model to support your strategic planning and KPI tracking initiatives.

Cost Per Ton Of Recycled Material

Tracking the cost per ton of recycled material is a crucial KPI metric for demolition waste recycling services like EcoDemolish Solutions. This financial KPI for recycling business allows management to measure the efficiency and profitability of recycling operations, ensuring that resources are allocated wisely.

The formula to calculate cost per ton is straightforward:

Cost Per Ton = Total Costs of Recycling / Total Tons of Material Recycled

For instance, if EcoDemolish Solutions incurs total costs of $50,000 and successfully recycles 1,000 tons of material, the cost per ton of recycled material would be:

Cost Per Ton = $50,000 / 1,000 = $50

This metric doesn't just help assess performance; it lays the groundwork for valuable recycling cost analysis metrics that inform business strategies and operational adjustments. Regularly monitoring this KPI aids in identifying trends and potential areas for cost reduction.

Tips to Improve Cost Efficiency

- Invest in technology that streamlines recycling processes, reducing manual labor and operational costs.

- Negotiate better contracts with waste suppliers to lower procurement costs.

- Enhance employee training compliance to maximize productivity and minimize errors in recycling operations.

In the broader context of demolition waste recycling KPIs, it's essential to benchmark against industry standards. For example, the construction and demolition waste recycling industry typically aims for a cost per ton ranging from $40 to $80 depending on various operational factors.

| Benchmark Metric | EcoDemolish Solutions | Industry Average |

|---|---|---|

| Cost Per Ton of Recycled Material | $50 | $40 - $80 |

| Percentage of Waste Diverted from Landfills | 75% | 60% - 80% |

| Average Turnaround Time for Recycling Projects | 3 days | 2 - 5 days |

By consistently measuring and analyzing the cost per ton of recycled material, EcoDemolish Solutions can make informed decisions that drive operational efficiency, ultimately leading to enhanced sustainability and profitability in the demolition waste recycling service business. Furthermore, aligning this metric with the company's recycling service strategic goals contributes to long-term success.

The data-driven approach to measure demolition waste performance can also aid in understanding client needs, thus enhancing customer satisfaction in waste services. This is vital as the company evolves and adapts to changing market conditions.

Percentage Of Waste Diverted From Landfills

One of the most critical KPI metrics for demolition waste recycling is the percentage of waste diverted from landfills. This metric measures the effectiveness of a recycling service in transforming what would otherwise be waste into valuable resources. By tracking this KPI, companies like EcoDemolish Solutions can assess their operational performance and sustainability efforts.

Calculating the percentage of waste diverted from landfills involves the following formula:

Percentage of Waste Diverted = (Total Waste Diverted / Total Waste Generated) x 100

This calculation not only highlights the volume of materials that are being successfully recycled but also reflects the company's commitment to sustainable practices. A high percentage indicates efficient waste recycling performance metrics and an organization focused on minimizing its environmental footprint. For instance, a target of diverting at least 75% of demolition waste should be a goal for most companies, as current industry benchmarks suggest that the average rate for effective recycling services ranges from 50% to 70%.

| KPI Type | Average Benchmark | EcoDemolish Solutions Target |

|---|---|---|

| Percentage of Waste Diverted from Landfills | 50% - 70% | 75% |

| Recycling Rate | 35% - 55% | 60% |

| Client Satisfaction Score | 70% - 85% | 90% |

In addition to tracking this KPI, companies should consider implementing strategies to improve their waste diversion rates:

Strategies to Improve Waste Diversion Rates

- Conduct regular audits of waste to identify recyclable materials.

- Enhance employee training on waste sorting practices to ensure compliance.

- Partner with local recycling facilities to expand recycling capabilities.

- Invest in better waste processing technologies to increase material recovery rates.

By focusing on the percentage of waste diverted from landfills, EcoDemolish Solutions not only enhances their operational efficiency ratio but also aligns with broader sustainability goals. Tracking this essential metric allows the business to measure its impact accurately and make informed decisions that drive both environmental and financial performance.

Ultimately, a higher diversion rate equates to a reduction in landfill costs and an improvement in revenue metrics for waste services. This leads to enhanced client satisfaction and a stronger competitive position in the demolition industry.

Average Turnaround Time For Recycling Projects

The average turnaround time for recycling projects is a critical KPI metric for demolition waste recycling services like EcoDemolish Solutions. This metric is essential in assessing the efficiency and effectiveness of recycling operations. In the highly competitive demolition and waste management industry, minimizing turnaround time can directly impact customer satisfaction and overall profitability.

To effectively measure the average turnaround time, businesses must consider the entire lifecycle of a recycling project, from initial assessment through to the final processing of materials. A benchmark for average turnaround times in the demolition waste recycling sector typically ranges between 3 to 10 days, depending on project complexity, material types, and operational efficiency.

| Project Type | Average Turnaround Time (Days) | Efficiency Rating |

|---|---|---|

| Residential Demolition | 3-5 | High |

| Commercial Demolition | 5-8 | Moderate |

| Industrial Demolition | 7-10 | Variable |

Calculating the average turnaround time involves tracking start and finish dates for each project. The formula is simple:

Average Turnaround Time = (Total Completion Time for All Projects) / (Number of Projects)

This KPI allows businesses to identify bottlenecks in the recycling process and implement strategies for improvement. For instance, if a certain project type consistently exceeds the average turnaround time, it may highlight areas needing operational refinement or resource allocation adjustments.

Tips for Reducing Turnaround Time

- Implement real-time tracking systems to monitor project progress.

- Conduct regular training sessions for employees to ensure compliance with operational standards.

- Use advanced sorting technologies to streamline the recycling process.

Furthermore, tracking this KPI not only aids in improving project timelines but also enhances overall client satisfaction. A decrease in the average turnaround time can lead to a 15-20% increase in client retention rates and positive word-of-mouth, which is invaluable in the waste management sector.

In the context of EcoDemolish Solutions, aligning the average turnaround time KPI with other operational KPIs can provide a comprehensive view of performance. For instance, coupled with the percentage of recycled materials and client satisfaction scores, businesses can gain insights into how quickly and effectively they are meeting sustainability goals.

Ultimately, maintaining a keen focus on the average turnaround time for recycling projects will not just enhance operational efficiency but will also solidify a company's reputation as a leader in environmental responsibility within the demolition waste recycling industry. For in-depth financial modeling and strategic planning for your demolition waste recycling service, consider exploring this resource: Demolition Waste Recycling Service Financial Model.

Client Satisfaction Score

In the competitive landscape of the demolition waste recycling service sector, the Client Satisfaction Score is a pivotal KPI that directly correlates with business success. At EcoDemolish Solutions, understanding and tracking this metric allows us to gauge our service quality and align our operations with client expectations. A high client satisfaction score not only fosters repeat business but also boosts referrals, which are crucial in this industry.

The Client Satisfaction Score can be calculated through various methodologies, including surveys, feedback forms, and direct customer interviews. Common questions might focus on service quality, timeliness, and overall client experience. Each feedback point can be rated on a scale, with results aggregated to formulate an overall score.

| Survey Element | Score (out of 10) | Weighting |

|---|---|---|

| Service Quality | 9 | 50% |

| Timeliness | 8 | 30% |

| Overall Experience | 9 | 20% |

| Composite Score | 8.5 | 100% |

Tracking this score is essential for several reasons:

- Guiding Improvement: Regular client feedback helps identify areas needing enhancement, ensuring continuous improvement in recycling services.

- Competitive Edge: Staying attuned to client needs enables EcoDemolish Solutions to outpace competitors who may neglect this essential metric.

- Performance Benchmarking: Comparing client satisfaction scores against industry standards provides insights into our market position.

To further strengthen client relationships and improve satisfaction, consider employing these strategies:

Tips for Improving Client Satisfaction in Recycling Services

- Implement a dedicated client feedback loop to capture insights post-service.

- Train employees to prioritize customer service, reinforcing the importance of client interactions.

- Utilize technology to streamline communication and service updates, ensuring clients feel informed throughout the recycling process.

Real-life statistics highlight that businesses which measure client satisfaction in waste services tend to experience up to a 25% increase in repeat clients. Additionally, a satisfaction score improvement can lead to a corresponding 10-15% rise in referral rates, underscoring the direct link between client experiences and business growth.

By integrating the Client Satisfaction Score into our KPI metrics for demolition waste recycling, EcoDemolish Solutions is not only enhancing operational efficiency but also driving our strategic goals forward. Aligning this metric with our sustainability commitment further positions us as leaders in the recycling service industry.

Revenue Growth Rate

The Revenue Growth Rate (RGR) is a critical KPI metric for demolition waste recycling services like EcoDemolish Solutions, as it quantifies the increase in revenue over a specific period, reflecting both business performance and market demand. A robust RGR indicates effective service delivery, increasing client demand, and operational efficiency in recycling processes.

To calculate the Revenue Growth Rate, the formula is as follows:

Revenue Growth Rate (%) = [(Current Period Revenue - Previous Period Revenue) / Previous Period Revenue] x 100

For instance, if EcoDemolish Solutions had a revenue of $500,000 in the previous year and $600,000 in the current year, the calculation would be:

RGR = [($600,000 - $500,000) / $500,000] x 100 = 20%

This 20% growth reflects significant engagement in sustainable practices and a strong market position in a competitive landscape. The RGR can be influenced by numerous factors, including:

- Increasing demand for sustainable demolition services as companies prioritize eco-friendly practices.

- Efficient project execution leading to a higher number of completed contracts.

- Enhanced client satisfaction leading to repeat business and referrals.

Tracking RGR alongside other core KPIs for recycling services, such as recycling rates and operational efficiency ratios, provides a comprehensive view of financial performance and overall health of the business.

Tips for Improving Revenue Growth Rate

- Invest in marketing strategies that highlight the environmental benefits of your recycling services to attract new clients.

- Enhance customer service to improve client satisfaction scores, which can lead to increased word-of-mouth referrals.

- Develop partnerships with construction firms and architects to establish a steady pipeline of demolition projects.

To provide a contextual benchmark, the industry standard for revenue growth in the waste management sector typically hovers between 5% to 10% annually. However, companies that actively pursue sustainability initiatives often see numbers exceeding this range, particularly as regulatory pressures increase and demand for greener practices grows.

| Year | Previous Period Revenue | Current Period Revenue | Revenue Growth Rate (%) |

|---|---|---|---|

| 2020 | $400,000 | $500,000 | 25% |

| 2021 | $500,000 | $600,000 | 20% |

| 2022 | $600,000 | $720,000 | 20% |

Utilizing this data, EcoDemolish Solutions can assess its revenue strategies and make informed decisions about future growth initiatives. Engaging in regular KPI calculation for the recycling business and maintaining focus on financial KPIs for recycling business will be essential for achieving long-term success.

Staying ahead in the demolition waste recycling industry requires not only tracking essential metrics but also aligning these KPIs with strategic goals. Investing in employee training in recycling compliance and operational efficiency can contribute significantly to enhancing the company's overall revenue trajectory, creating a positive feedback loop for future growth.

For businesses looking to streamline their financial planning and projections, consider leveraging tools designed for this purpose. Check out the comprehensive financial model tailored specifically for demolition waste recycling services: Financial Model for Demolition Waste Recycling Service.

Operational Efficiency Ratio

The Operational Efficiency Ratio (OER) is a critical KPI metric for demolition waste recycling businesses like EcoDemolish Solutions. It measures how effectively resources are utilized in the recycling process, providing vital insight into operational performance. A high OER indicates that a company is maximizing its outputs relative to the inputs, which is essential for staying competitive in the recycling industry.

To calculate the OER for your demolition waste recycling services, you can use the following formula:

| Metric | Formula | Example Value |

|---|---|---|

| Operational Efficiency Ratio (OER) | (Total Revenue from Recycled Materials) / (Total Operational Costs) | 1.5 |

In this formula, Total Revenue from Recycled Materials reflects the income generated from the sale of recycled materials, while Total Operational Costs include expenses such as labor, equipment, and facility maintenance. An OER above 1 indicates that the business is operating efficiently, while a ratio below 1 suggests that operational costs may be too high relative to revenues.

Benchmarks for the demolition waste recycling industry often indicate that a healthy OER ranges from **1.3 to 2.0**. Businesses should aim for this range to ensure they are capitalizing on their recycling capacity effectively.

Tips for Improving Your Operational Efficiency Ratio

- Regularly review operational costs to identify areas for potential savings.

- Implement technology to streamline processes and reduce labor intensity.

- Maximize the value of recycled materials through strategic partnerships and market analysis.

- Encourage employee training and compliance to enhance productivity and reduce errors.

Tracking the OER is not only crucial for understanding current performance but also plays a significant role in strategic decision-making for future growth. By consistently measuring and analyzing your operational efficiency, you can make informed adjustments to improve overall profitability and sustainability in your demolition waste recycling service.

Furthermore, integrating regular KPI reviews—at least quarterly—into your operational strategy can enhance responsiveness to market changes, ensuring that your business remains agile and competitive in the demolition waste industry.

For a deeper dive into financial models tailored for demolition waste recycling services, consider exploring comprehensive resources like the demolition waste recycling service financial model.

Material Recovery Rate

The **Material Recovery Rate (MRR)** is a pivotal KPI metric for demolition waste recycling services, such as **EcoDemolish Solutions**. This metric quantifies the percentage of material recovered from waste generated during demolition projects as compared to the total amount of waste produced. Tracking MRR not only helps measure demolition waste performance but also aligns with sustainability goals critical in today's construction environment.

To calculate the MRR, the formula is:

Material Recovery Rate (%) = (Total Recovered Materials / Total Demolition Waste Generated) x 100

For example, if a project generates **100 tons** of waste and **70 tons** are successfully recycled, the MRR would be:

(70 / 100) x 100 = 70%

This high recovery rate indicates an efficient recycling process and a strong commitment to minimizing landfill waste. The industry benchmark for MRR in demolition waste recycling services typically ranges from **50% to 90%**, depending on the type of materials and local regulations.

| Year | Material Recovery Rate | Industry Benchmark |

|---|---|---|

| 2021 | 62% | 50% - 70% |

| 2022 | 75% | 60% - 80% |

| 2023 | 85% | 70% - 90% |

By focusing on the MRR, **EcoDemolish Solutions** can also enhance client satisfaction. Clients are increasingly concerned about environmental impacts, and demonstrating a high recovery rate can be a selling point that builds trust and credibility.

Tips for Improving Material Recovery Rate

- Invest in advanced sorting technology to separate recyclables from non-recyclables more effectively.

- Train employees on best practices for material recovery and compliance to maximize efficiency.

- Collaborate with local recycling facilities to ensure materials are processed effectively.

Tracking the Material Recovery Rate not only allows **EcoDemolish Solutions** to measure operational efficiency but also serves as a basis for important financial KPIs for recycling business. A robust MRR can lead to decreased disposal costs, enhanced revenue through increased recycled material sales, and improved overall profitability.

Ultimately, maintaining a high Material Recovery Rate aligns with long-term strategic goals of sustainability and operational excellence, positioning **EcoDemolish Solutions** as a leader in the demolition waste recycling industry.

For a comprehensive understanding of how to effectively measure and enhance your business's MRR and overall performance, consider using a detailed financial model tailored for demolition waste recycling services. This can help streamline KPI calculations and provide insightful analysis on your operational metrics. Explore more at Demolition Waste Recycling Service Financial Model.

Employee Training Compliance Rate

The Employee Training Compliance Rate is a critical KPI for a demolition waste recycling service business like EcoDemolish Solutions. This metric measures the percentage of employees who have completed mandatory training programs related to recycling processes, safety protocols, and sustainability practices. Ensuring compliance in training is essential not only for operational efficiency but also for maintaining high standards in waste recycling performance.

To calculate the Employee Training Compliance Rate, use the following formula:

Employee Training Compliance Rate (%) = (Number of Employees Trained / Total Number of Employees) x 100

This KPI serves multiple purposes:

- Ensures Safety: Trained employees are less likely to make mistakes that could lead to unsafe conditions.

- Boosts Efficiency: Proper training can significantly decrease operational delays and increase productivity on demolition projects.

- Aids in Compliance: Meeting regulatory training requirements helps avoid legal issues and potential fines.

The industry standard for Employee Training Compliance Rates in waste management and recycling services is generally around 85%-90%, depending on the complexity of the operations. However, aiming for a compliance rate of 100% should be the ultimate goal for EcoDemolish Solutions, as it reflects a commitment to excellence in training and operational performance.

| KPI | Target Rate | Current Rate |

|---|---|---|

| Employee Training Compliance Rate | 100% | 85% |

| Safety Incident Rate | 0 | 2 |

| Operational Efficiency Ratio | 1.0 | 0.75 |

Maintaining a high Employee Training Compliance Rate is linked not only to safety but also to client satisfaction and operational success. For EcoDemolish Solutions, a well-trained workforce can lead to better recycling outcomes, as employees who understand the processes are more likely to maximize resource recovery.

Tips for Improving Employee Training Compliance Rate

- Incorporate regular training refreshers to ensure knowledge retention.

- Utilize e-learning platforms for accessible training modules.

- Implement a rewards program that recognizes employees for completing training on time.

Moreover, tracking compliance provides a basis for accountability. By setting up a system where employees can easily report their training status, EcoDemolish Solutions can foster a culture of continuous learning and development. This commitment to employee training not only enhances labor efficiency but also ensures that operational KPIs are met, benefiting the overall demolition waste recycling process.

As EcoDemolish Solutions positions itself at the forefront of sustainability and resource recovery, the Employee Training Compliance Rate will be pivotal in achieving strategic goals. Integrating this KPI into the broader framework of financial and operational metrics ensures a comprehensive approach to measuring demolition waste performance. For detailed financial modeling and strategies tailored for demolition waste recycling services, explore [this link](https://financialmodeltemplates.com/products/demolition-waste-recycling-service-financial-model).