Related Blogs

Curious about the financial landscape of launching an engine manufacturing business? Understanding the top nine startup costs is crucial for aspiring entrepreneurs. From machinery and equipment to licensing and regulatory compliance, each expense can significantly impact your budget. Are you ready to dive deeper into these costs and see how a solid business plan can pave your way to success? Explore more at this link.

How Much Does It Cost To Start An Engine Manufacturing Company?

Starting an engine manufacturing company, such as Engine Innovations Corp, involves considerable initial investment. The engine manufacturing startup costs can vary significantly based on the scale of the operation, technology employed, and the market segment targeted. On average, entrepreneurs can expect to invest between $500,000 to $2 million to launch a small to medium-sized engine production business.

Key components of the costs to start an engine manufacturing company include:

- Machinery and Equipment Costs: This can range from $200,000 to $1 million, depending on the type of engines produced and the level of automation required. High-performance machinery is essential for precision manufacturing.

- Facility Lease or Purchase Costs: Renting a facility typically costs between $2,000 to $10,000 per month, while purchasing a property can require an upfront investment of $300,000 to $1 million.

- Raw Materials and Supplies Costs: Initial procurement of raw materials for engine manufacturing can range from $50,000 to $300,000, depending on the materials used and the volume of production.

- Research and Development Expenses: Allocating around $50,000 to $150,000 for R&D is crucial to innovate and comply with industry standards.

- Licensing and Regulatory Compliance Costs: These can range from $10,000 to $100,000, depending on the regulatory landscape of the region where the business operates.

- Technology and Software Investments: Investing in advanced manufacturing software and technology can cost between $20,000 to $200,000.

- Marketing and Branding Expenses: Initial marketing costs can range from $10,000 to $50,000 to create brand awareness and attract customers.

- Initial Recruitment and Training Costs: Hiring skilled labor and training them may require an investment of $30,000 to $100,000.

- Insurance and Legal Fees: These expenses can vary widely, but budgeting around $5,000 to $20,000 is advisable to cover basic insurance and legal requirements.

In total, the initial investment in engine manufacturing can be substantial, but understanding these detailed expenses of starting an engine manufacturing company can help in effective budgeting and planning. For more insights on profitability in this sector, you can refer to this article.

Tips for Reducing Startup Costs

- Consider leasing machinery instead of purchasing to lower initial expenses.

- Explore grants and funding opportunities specifically designed for manufacturing startups.

- Utilize a co-working space or shared manufacturing facility to reduce facility costs.

By strategically planning and understanding the various engine manufacturing company investment aspects, entrepreneurs can better navigate the complexities of starting their business and ensure a smoother launch process.

Is It Possible To Start An Engine Manufacturing Company With Minimal Investment?

Starting an engine manufacturing company, such as Engine Innovations Corp, with minimal investment is challenging but not impossible. The typical startup costs for engine production can range from $250,000 to over $2 million, depending significantly on the scale and complexity of operations. However, with strategic planning and resource management, it is feasible to reduce these costs substantially.

To begin with, entrepreneurs can focus on affordable engine manufacturing startup costs by considering the following strategies:

- Lean Manufacturing Principles: Adopting a lean approach helps eliminate waste and minimize the necessary engine manufacturing equipment expenses. This can include reducing overproduction, optimizing inventory, and streamlining processes.

- Renting Instead of Buying: Instead of purchasing a facility outright, renting a space for engine manufacturing can significantly cut initial investments. Renting also allows flexibility to scale operations as needed.

- Outsourcing Non-Core Functions: By outsourcing research and development or administrative tasks, companies can save on costs while concentrating on core engine production activities.

- Utilizing Second-Hand Machinery: Investing in used but reliable engine manufacturing machinery can drastically reduce initial costs, with potential savings of up to 50% compared to new equipment.

- Developing In-House Talent: Hiring experienced engineers may seem costly at first; however, investing in training for existing employees can be a more economical long-term strategy.

Furthermore, securing funding for engine manufacturing startups can provide additional financial flexibility. Potential sources include:

- Small Business Loans: Many financial institutions offer loans specifically tailored for manufacturing startups, sometimes with lower interest rates.

- Crowdfunding: Platforms like Kickstarter or Indiegogo can be effective in raising funds while simultaneously gauging market interest.

- Government Grants and Incentives: Investigating local and federal grants aimed at promoting green technologies can provide financial support for environmentally friendly engine solutions.

Additionally, understanding regulatory costs for engine businesses and diligently budgeting for them can prevent unexpected financial burdens. Licensing requirements may vary, and startup companies should prepare for potential regulatory costs of about 5-10% of total startup expenses.

Ultimately, it is possible to start an engine manufacturing company on a budget, but it requires careful planning, market awareness, and strategic financial management. For detailed insights into the engine manufacturing industry, consider exploring resources that provide comprehensive data on this topic, such as this article.

Which Costs Can Be Reduced for an Engine Manufacturing Company?

Starting an engine manufacturing company, such as Engine Innovations Corp, can incur significant costs. However, there are several expenses that can be strategically minimized to enhance profitability and sustainability. By focusing on the following areas, startups can alleviate some of their financial burdens:

1. Machinery and Equipment Costs

Investing in engine manufacturing equipment often represents one of the largest upfront costs. To reduce this burden, consider:

- Leasing equipment instead of purchasing outright, which can lower initial investment in engine manufacturing.

- Buying used machinery in good condition, which can be significantly cheaper than new models.

2. Facility Lease or Purchase Costs

Renting a facility is often more cost-effective than purchasing real estate. Additionally, selecting a location outside of high-rent districts can provide substantial savings:

- Consider co-sharing a manufacturing space with another company or utilizing smaller facilities initially.

- Negotiate long-term leases to lock in lower rental rates.

3. Raw Materials and Supplies Costs

Raw materials for engine manufacturing can be a significant factor in engine production business expenses. Strategies for reducing these costs include:

- Establishing strong relationships with suppliers to negotiate better prices.

- Purchasing in bulk or forming cooperatives with other manufacturers to gain volume discounts.

4. Research and Development Expenses

Budgeting for engine manufacturing research can be crucial, but costs can be managed by:

- Leveraging grants and subsidies available for innovation in green technologies, which can offset R&D costs.

- Utilizing in-house talent to minimize hiring costs for specialized research consultants.

5. Licensing and Regulatory Compliance Costs

Regulatory costs for engine businesses can accumulate rapidly. To manage these:

- Seek guidance from industry associations that may offer resources or lower-cost compliance services.

- Invest in the necessary training for staff to ensure compliance, which can reduce reliance on external consultants.

6. Technology and Software Investments

Investing in technology is essential, but it doesn't need to break the bank. Companies can:

- Utilize open-source software solutions where possible to reduce software licensing fees.

- Cloud-based solutions can eliminate the need for costly hardware, with subscription models often being more affordable.

7. Marketing and Branding Expenses

Marketing costs for engine manufacturers can be minimized by:

- Utilizing social media and digital marketing strategies, which often have lower costs compared to traditional advertising.

- Networking within industry events instead of paying for large-scale promotional campaigns.

8. Initial Recruitment and Training Costs

While attracting talent is vital, initial recruitment and training costs can be high; consider:

- Hiring interns or apprentices, who can provide support at a reduced cost while gaining valuable experience.

- Implementing online training programs that can be more cost-effective than traditional training methods.

9. Insurance and Legal Fees

Insurance and legal fees are often unavoidable, but may be reduced by:

- Shopping around for the best rates and bundling policies for substantial savings.

- Consulting with a legal expert for a one-time fee instead of retaining a legal firm on an ongoing basis.

Tips for Reducing Startup Costs

- Conduct thorough market research to identify the most cost-effective suppliers and locations.

- Engage with local business development programs that can provide resources and guidance on cost reduction.

By effectively managing these areas, startups in the engine manufacturing sector can significantly reduce their startup expenses for engine manufacturers and enhance their investment potential. For further insights, consider reading this resource on opening an engine manufacturing business.

Examples of Startup Budgets for Engine Manufacturing Companies

Starting an engine manufacturing business, such as Engine Innovations Corp, requires meticulous planning and a clear understanding of potential costs. A well-structured startup budget can help you navigate the financial landscape of this industry. Below are examples of expected startup costs for an engine manufacturing company, focusing on both fixed and variable expenses.

1. Machinery and Equipment Costs

The costs for engine manufacturing machinery can vary significantly based on the technology used and production capacity. A basic setup might range from $200,000 to $1 million, depending on whether you choose new or refurbished equipment. Consider:

- Automated assembly lines

- Testing and calibration tools

- Machining equipment

2. Facility Lease or Purchase Costs

Renting a facility for engine manufacturing typically costs between $3,000 to $10,000 monthly, depending on the location and size. Purchasing a facility could require an upfront investment of $500,000 to $2 million. Location is crucial, so research areas that offer industry incentives.

3. Raw Materials and Supplies Costs

Initial investment in raw materials for engine manufacturing may account for 10-20% of your startup budget, varying widely based on materials used, such as metals, plastics, and composites. Expect to spend around $100,000 to $300,000 initially.

4. Research and Development Expenses

Budgeting for engine manufacturing research is essential for innovation. R&D expenses could range from $50,000 to $500,000, depending on the complexity of the designs and technologies pursued.

5. Licensing and Regulatory Compliance Costs

Startups must account for regulatory costs for engine businesses. Securing licenses can cost between $5,000 to $25,000 depending on the requirements of your jurisdiction and the specific regulations governing engine manufacturing.

6. Technology and Software Investments

Investing in software for design and production management will range from $10,000 to $100,000. Consider subscriptions for CAD software, resource planning systems, and other specialized tools.

7. Marketing and Branding Expenses

Marketing costs for engine manufacturers can vary widely, but a budget of $10,000 to $50,000 for initial branding, website development, and promotional materials is advisable to establish a market presence.

8. Initial Recruitment and Training Costs

Forecast initial recruitment and training costs to be around $20,000 to $100,000, depending on the number of employees and level of expertise required.

9. Insurance and Legal Fees

Finally, securing insurance and legal services is crucial. Allocate about $5,000 to $20,000 for insurance coverage and legal fees to ensure compliance and protection for your engine manufacturing business.

Tips for Budgeting Effectively

- Prioritize essential expenses to avoid overspending on non-critical areas.

- Look for grants and funding opportunities specifically for innovative manufacturing startups.

- Evaluate options for renting vs. buying machinery to optimize initial investment.

Overall, a well-planned startup budget for an engine manufacturing company could total anywhere from $500,000 to $3 million, depending on your specific business model and goals. For more detailed insights, explore resources like this article that discusses engine manufacturing costs in-depth.

How to Secure Enough Funding to Start an Engine Manufacturing Company?

Securing adequate funding for your engine manufacturing company is crucial, given the significant startup expenses for engine manufacturers, which can range from hundreds of thousands to millions of dollars. To address the engine manufacturing startup costs, a well-structured funding strategy is essential.

Consider exploring various funding options that align with your business goals and financial requirements:

- Personal Savings: Many entrepreneurs begin by investing their personal savings. This often represents the first step in covering initial costs.

- Loans and Grants: Look for small business loans specifically designed for manufacturing. Government grants are also available, particularly for companies focusing on innovation and sustainability.

- Angel Investors and Venture Capital: These investors seek innovative ideas in the manufacturing sector. Present a solid business plan highlighting your unique approach in the engine production business.

- Crowdfunding: Platforms such as Kickstarter or Indiegogo allow you to showcase your engine innovations to the public, gaining both financial support and market interest.

- Partnerships: Collaborating with established companies in the automotive or aerospace sectors can provide not only funding but also valuable industry insights and resources.

A well-prepared business plan is vital in persuading potential investors or lenders. Include detailed projections of engine manufacturing startup budget, covering:

- Machinery and Equipment Costs: Estimated to start at around $500,000 for essential equipment.

- Facility Leasing Costs: Renting a facility for engine manufacturing can range between $5,000 and $20,000 per month, depending on location.

- Raw Materials Expenses: Initial investment in materials such as metals and composites can exceed $200,000.

- Research and Development Budget: Allocating at least 15% of your total budget towards R&D can significantly enhance your product's innovation.

- Marketing Costs: Setting aside approximately $50,000 for marketing ensures effective outreach to potential clients.

Tips for Securing Funding

- Develop a pitch deck that outlines your vision, unique selling proposition, and projected profitability.

- Network with industry professionals to identify potential investors interested in funding new technologies in the engine manufacturing sector.

- Research and adhere to licensing requirements for engine manufacturers to ensure compliance, as this affects investors' confidence.

Overall, the key to successfully securing funding for your engine manufacturing company lies in presenting a compelling business case that reflects a thorough understanding of the costs of machinery in engine production, the potential return on investment, and the market opportunity within the industry.

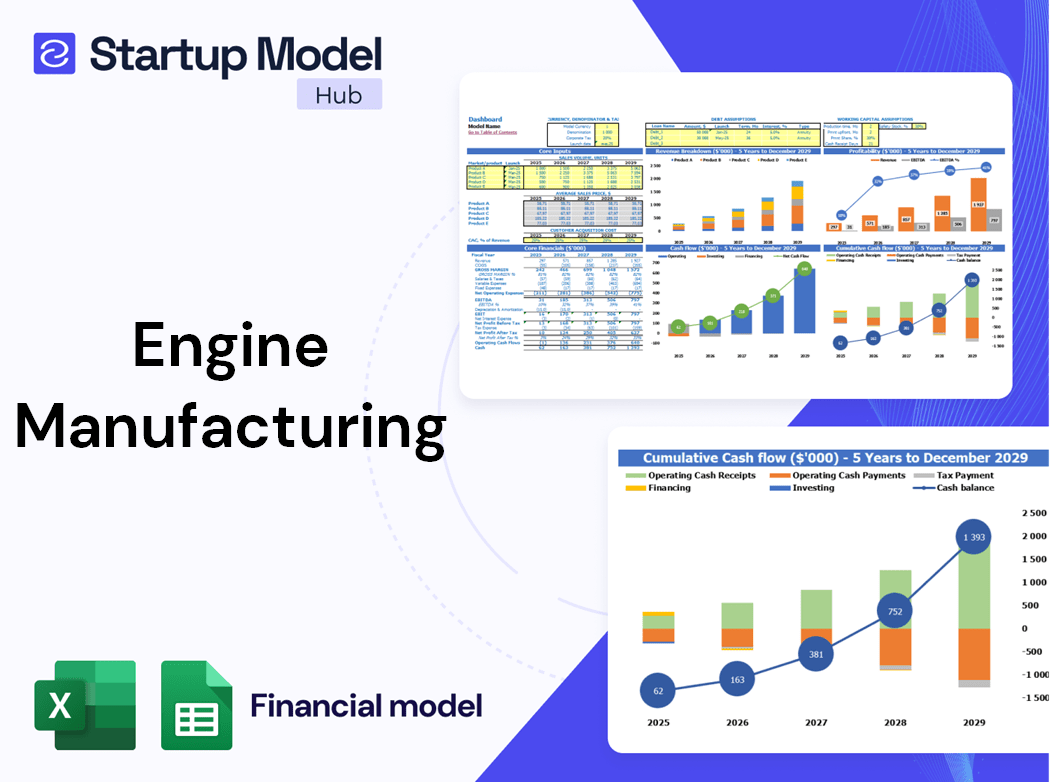

How to Use the Financial Plan for Your Engine Manufacturing Company?

Creating a robust financial plan is a critical step in launching your engine manufacturing business, such as Engine Innovations Corp, which aims to deliver innovative, eco-friendly engine solutions. A well-structured financial plan not only serves as a roadmap for your startup but is also essential in attracting investors and securing funding for engine manufacturing startups.

Your financial plan should include several key components to effectively guide your business operations:

- Startup Costs Estimation: Accurately calculate engine manufacturing startup costs by itemizing your expenses, such as machinery, leasing a facility, and raw materials. It's crucial to account for all initial investments, estimated to range from $500,000 to $1 million depending on the scale of your operations.

- Revenue Projections: Develop realistic sales forecasts based on market research. For instance, the engine manufacturing market is projected to grow at a CAGR of 4.5% from 2021 to 2028, providing a significant opportunity for new entrants.

- Break-Even Analysis: Determine how long it will take to cover your startup expenses for engine manufacturers. Understanding your break-even point is crucial for strategic decision-making.

In addition, you should also consider operating expenses that will occur after your launch. These may include:

- Fixed Costs: Rent, utilities, and salaries should be calculated to maintain business continuity while allowing for unexpected fluctuations in production.

- Variable Costs: Include raw materials for engine manufacturing and marketing costs for engine manufacturers, which can fluctuate based on production rates and market conditions.

Tips for Developing a Financial Plan:

- Conduct thorough market research to justify your revenue projections and to identify potential clients in the automotive and aerospace sectors.

- Review similar businesses to understand the costs of machinery in engine production and operational expenses.

- Seek feedback from financial experts or mentors to refine your financial model.

Finally, it’s important to monitor and adjust your financial plan based on actual performance metrics. Regular reviews can help identify discrepancies and opportunities for cutting costs in engine production. Having a solid financial plan in place will not only help you gauge your company's financial health but also support you in securing funding by demonstrating a viable investment opportunity.

What Are The Expenses To Start An Engine Manufacturing Company?

Starting an engine manufacturing company like Engine Innovations Corp requires a careful analysis of various expenses involved in the process. The engine manufacturing startup costs can be substantial, often reaching into the millions, depending on the scale and complexity of the operations. Below are the primary expenses to consider:

Machinery and Equipment Costs

Investing in the right machinery is crucial for quality production. The costs for engine manufacturing machinery can range from $500,000 to over $2 million depending on the technology used. This includes CNC machines, assembly lines, and specialized tools.

Facility Lease or Purchase Costs

Renting or purchasing a facility for engine manufacturing can also contribute significantly to your expenses. Monthly leasing costs can vary widely but generally fall between $5,000 to $20,000, while purchasing a facility may require an initial investment of $1 million to $5 million.

Raw Materials and Supplies Costs

Costs for engine manufacturing raw materials, such as metals, plastics, and composites, need to be factored in. Initial inventory can cost around $200,000 to $500,000, depending on your production volume and product specifications.

Research and Development Expenses

R&D is essential for innovation, particularly in environmentally friendly technologies. Budgeting for engine manufacturing research can require an investment of $100,000 to $500,000 in the initial stages.

Licensing and Regulatory Compliance Costs

Adhering to licensing requirements for engine manufacturers can incur regulatory costs estimated at $10,000 to $50,000. This includes certifications and meeting environmental standards.

Technology and Software Investments

Technology is a significant element in production efficiency. Invest approximately $50,000 to $200,000 in software solutions for design and manufacturing processes.

Marketing and Branding Expenses

Effective marketing is crucial for reaching potential clients in the automotive and aerospace sectors. Initial marketing costs for engine manufacturers can be around $20,000 to $100,000 to establish brand presence.

Initial Recruitment and Training Costs

Hiring skilled workers is vital for successful operations. Initial recruitment and training costs can range from $50,000 to $200,000 to ensure a knowledgeable workforce.

Insurance and Legal Fees

Last but not least, business insurance and legal fees should not be overlooked. Anticipate around $10,000 to $30,000 for insurance and legal setup.

Tips for Cutting Costs in Engine Production

- Consider leasing equipment instead of purchasing to minimize initial investment in engine manufacturing.

- Utilize technology to optimize production processes and reduce waste.

The detailed expenses of starting an engine manufacturing company can be extensive but are necessary to consider for a successful launch. To support strategic budgeting, review resources such as this detailed guide on engine manufacturing startup budgets.

Machinery and Equipment Costs

Starting an engine manufacturing company like Engine Innovations Corp involves various expenses, with machinery and equipment standing out as one of the most significant components of your startup costs. The costs associated with machinery can range from hundreds of thousands to millions of dollars, depending on the scale of your operation and the level of technology you choose to implement.

In general, the machinery and equipment costs for an engine manufacturing company can be broken down into several main categories:

- Engine Assembly Lines: These are essential for the mass production of engines and can vary widely in price based on the complexity and automation level, often costing between $500,000 to $2 million.

- Specialized Tools and Equipment: This includes machine tools like lathes, milling machines, and CNC machines necessary for precision manufacturing, typically costing between $100,000 to $750,000.

- Testing and Quality Assurance Equipment: Ensuring that the engines meet safety and performance standards requires testing machinery, which can cost $50,000 to $200,000.

- Maintenance and Repair Tools: Investing in a good set of maintenance tools is crucial to keep the machinery running smoothly, which may range from $20,000 to $100,000.

These machinery and equipment expenses contribute significantly to the overall startup budget for engine manufacturers. Below is a sample budget breakdown for machinery expenses:

| Machinery Type | Estimated Cost | Purpose |

|---|---|---|

| Engine Assembly Line | $1,000,000 | Mass production |

| CNC Machines | $300,000 | Precision cutting |

| Quality Testing Equipment | $100,000 | Performance testing |

| Maintenance Tools | $50,000 | Machine upkeep |

As you strategize on affordable engine manufacturing startup costs, consider ways to optimize your machinery investment:

Tips for Reducing Machinery Costs

- Consider leasing equipment rather than purchasing upfront to reduce initial capital outlay.

- Research second-hand machinery options for cost-effective yet reliable equipment.

- Explore partnerships with suppliers that might offer discounts for bulk purchasing or long-term contracts.

In addition to initial investment in engine manufacturing equipment, ongoing maintenance and operation costs must also be factored into your budget. It's vital to conduct thorough research to ensure that your engine production business expenses are accurately represented in your financial projections. By doing so, you’re positioning your startup for success in a competitive market.

Ensure compliance with regulatory costs for engine businesses, as many jurisdictions require specific certifications and standards that can also influence your machinery choice. Investing in top-notch equipment not only helps in producing high-quality engines but also builds a reputation for reliability that attracts potential clients.

With accurate budgeting for engine manufacturing equipment expenses and understanding the long-term financial implications, you will be better equipped to secure the necessary funding for your engine manufacturing startup and achieve sustainable growth in the industry. For a more detailed financial plan, look into resources that provide comprehensive templates tailored specifically for engine manufacturing financial modeling, such as those available at this link.

Facility Lease or Purchase Costs

The costs associated with leasing or purchasing a facility are crucial components of the overall engine manufacturing startup costs. Selecting the right location impacts not only the initial investment but also the operational efficiency of your engine production business. In general, the decision to lease or buy a facility hinges on several factors, including budget, long-term goals, and local market conditions.

In the engine manufacturing industry, facility costs can range significantly based on geographical location, size, and the specific needs of your business. Typically, businesses budget between $10 to $30 per square foot for leasing industrial space, which can vary greatly depending on the region. In high-demand areas, costs can soar, with some locations charging as much as $50 to $100 per square foot. Here's a breakdown:

| Location | Lease Cost (per sq. ft.) | Purchase Cost (per sq. ft.) |

|---|---|---|

| Urban Area | $30 - $50 | $200 - $300 |

| Suburban Area | $15 - $25 | $150 - $250 |

| Rural Area | $10 - $20 | $100 - $200 |

The decision to lease or purchase also comes down to the initial investment in engine manufacturing and projected cash flow. Leasing often requires a lower upfront investment, which can be ideal for startups. However, owning a facility can lead to long-term savings and equity building. In addition to the leasing or purchasing price, consider the following expenses:

- Renovation and Upfitting Costs: Depending on the existing structure, you may have to invest in renovations to make the space suitable for engine manufacturing.

- Utility Setup: Costs associated with setting up water, electricity, gas, and internet services can add up quickly.

- Property Taxes: If you purchase a facility, be mindful of property taxes, which can vary significantly by location.

- Insurance: Secure appropriate insurance that covers the facility and any potential liabilities.

Tips for Managing Facility Costs

- Explore flexible leasing options that allow you to scale as your business grows.

- Consider co-locating with other businesses to share facility costs and resources.

- Research local real estate markets to find more affordable options without sacrificing necessary infrastructure.

In addition to the direct costs for the facility, it's essential to include expenses for starting an engine company, such as installation of specialized machinery, safety compliance upgrades, and any necessary modifications to accommodate the specific requirements of engine production. For a successful engine manufacturing startup, a detailed understanding of these facility-related costs will be paramount to developing a realistic engine manufacturing startup budget.

Finally, while planning for the costs of leasing or purchasing your facility, it’s advisable to also maintain a contingency fund. This fund should cover unexpected expenses that may arise during the setup of your engine manufacturing operation. Securing funding for engine manufacturing startups can help offset these costs and ensure that you have the necessary resources to create a state-of-the-art production facility. For detailed financial planning and projections, consider utilizing resources like engine manufacturing financial models to support your budgeting and investment strategy.

Raw Materials and Supplies Costs

When establishing an engine manufacturing company, one of the most significant portions of the startup expenses for engine manufacturers will revolve around the cost of raw materials and supplies. For a business like Engine Innovations Corp, which aims to deliver innovative and environmentally friendly engine solutions, identifying the right materials is crucial. The quality of raw materials not only affects the manufacturing costs but also the final product's performance and compliance with regulatory standards.

The actual costs of raw materials for engine manufacturing can vary widely depending on several factors, including:

- Material Type: Common materials include aluminum, steel, composites, and high-performance alloys. Prices can range from $1,500 to $3,500 per ton depending on market conditions.

- Supplier Relationships: Establishing long-term contracts with suppliers can help negotiate better pricing and secure consistent material supply, impacting the engine manufacturing startup budget.

- Volume of Purchase: Bulk orders can often reduce costs significantly. For example, purchasing 100 tons of a specific alloy might yield a discount of 10-20% compared to smaller orders.

- Location: Proximity to suppliers can influence shipping costs, which need to be factored into overall material expenses.

Let's break down some typical raw material costs associated with starting an engine manufacturing company:

| Material | Estimated Cost per Ton | Typical Usage (tons/year) | Total Cost per Year |

|---|---|---|---|

| Aluminum | $2,000 | 50 | $100,000 |

| Steel | $1,500 | 30 | $45,000 |

| High-Performance Alloys | $3,500 | 20 | $70,000 |

In total, the raw materials can account for a substantial portion of the initial investment in engine manufacturing, often making up to 30-40% of the total engine production business expenses.

Tips for Managing Raw Material Costs

- Research the market trends for raw materials frequently to purchase at the right time.

- Consider alternative materials that might be more cost-effective yet meet performance criteria.

- Implement a just-in-time inventory system to reduce storage costs and waste.

Another important aspect to consider is the regulatory costs for engine businesses. Some materials may require certifications or special handling, impacting initial costs. Additionally, costs of machinery in engine production can vary based on the technology required for processing these materials, sometimes necessitating a higher initial investment.

In conclusion, raw materials and supplies represent a significant component of startup costs for engine production. Efficient management in this area can lead to optimized production costs, which is essential for the success of any new engine manufacturing venture.

Research and Development Expenses

In the **engine manufacturing** industry, **research and development (R&D) expenses** play a critical role in driving innovation and maintaining competitive advantage. For an **engine manufacturing startup**, the initial investment in R&D can significantly impact the long-term success of the business. It is essential to allocate a portion of the startup budget to R&D, particularly in a field where technology and efficiency are constantly evolving.

On average, R&D spending for **engine manufacturing companies** can range from **5% to 15% of total revenue**. For a new **engine production business**, this could translate into several thousand dollars in initial startup costs, depending on the scale and complexity of the projects undertaken. Below is a breakdown of potential R&D expenses:

| Expense Type | Estimated Cost | Potential Duration |

|---|---|---|

| Prototype Development | $50,000 - $200,000 | 6 - 12 months |

| Material Testing | $20,000 - $100,000 | 3 - 6 months |

| Compliance Testing | $10,000 - $50,000 | 3 - 6 months |

| Consultation with Experts | $5,000 - $30,000 | Ongoing |

Investing in R&D is crucial for **Engine Innovations Corp** as it focuses on developing innovative and environmentally friendly engine solutions. The costs associated with R&D can include:

- Hiring skilled engineers and scientists who specialize in engine technology.

- Laboratory equipment and testing facilities to develop and refine engine prototypes.

- Materials for prototype engines—these raw materials can be costly but are necessary for testing performance and emissions.

- Licensing fees for proprietary technologies and patents that could enhance product offerings.

- Incorporating advanced simulation software to model engine performance before physical production.

Tips for Budgeting R&D Expenses

- Conduct a thorough market analysis to identify trends and technological needs in the industry, which will help prioritize R&D projects.

- Leverage partnerships with universities or research institutions that could reduce costs and provide access to advanced research facilities.

- Apply for government grants or subsidies that support innovation in engineering and manufacturing.

R&D expenses are just one part of the **startup expenses for engine manufacturers**. While initial investment might seem high, the long-term benefits of innovation—such as improved engine efficiency and compliance with environmental regulations—can lead to substantial returns. As the company grows, ongoing investment in R&D will ensure that **Engine Innovations Corp** remains at the forefront of the engine manufacturing industry. Understanding the specific **costs to start an engine manufacturing company**, including R&D, is essential for effective budgeting and securing **funding for engine manufacturing startups**. A well-structured financial plan will not only cover these essential expenses but also provide a roadmap for sustainable growth in an evolving market. For those interested in a detailed financial model, visit [Engine Manufacturing Financial Model](https://financialmodeltemplates.com/products/engine-manufacturing-financial-model).

Licensing and Regulatory Compliance Costs

When embarking on the journey to establish an engine manufacturing company, one of the critical aspects to consider is the licensing and regulatory compliance costs. These costs vary significantly based on the type of engines being produced, the specific regulations of the region where the business operates, and the intended markets. For a company like Engine Innovations Corp, which aims to revolutionize the engine manufacturing sector by focusing on innovative and environmentally friendly solutions, understanding these costs is vital to ensure compliance and operational success.

The costs to start an engine manufacturing company can include the following:

- Licensing Fees: These are mandatory fees paid to governmental departments to obtain the necessary permits and licenses for manufacturing engines. Depending on the jurisdiction, these fees can range from $1,000 to $50,000.

- Regulatory Compliance Costs: Expenses related to meeting industry standards, such as emissions and safety regulations, can add up quickly. Companies often spend 10-15% of their total startup budget on compliance-related activities.

- Certification Costs: In order to ensure that the engines meet specific quality and safety standards, manufacturers often incur certification costs. These can vary based on the certifications required but typically range from $5,000 to $100,000.

- Consultation and Legal Fees: Hiring regulatory consultants or legal aides to navigate the complex landscape of regulatory requirements is an essential expense. This could cost anywhere from $2,000 to $25,000 depending on the complexity of the business model.

- Research and Development for Compliance: Companies may need to invest additional funds in R&D to ensure their products align with the latest regulations. This can add up to 20-30% of the initial investment in engine manufacturing.

These estimated costs highlight the importance of incorporating comprehensive startup expenses for engine manufacturers into your financial planning. The investment in compliance is not merely a cost but rather a safeguard that can prevent operational disruptions and potential fines down the line.

Tips for Managing Licensing and Regulatory Compliance Costs

- Invest in robust compliance software to track regulatory changes efficiently and reduce consultancy costs.

- Join industry associations that can provide insights on compliance standards and shared resources to lower costs.

- Regularly conduct internal audits to identify any compliance gaps, which can save costs associated with penalties.

| Cost Item | Estimated Cost Range | Percentage of Startup Budget |

|---|---|---|

| Licensing Fees | $1,000 - $50,000 | 1 - 5% |

| Regulatory Compliance Costs | - | 10 - 15% |

| Certification Costs | $5,000 - $100,000 | 3 - 10% |

| Consultation and Legal Fees | $2,000 - $25,000 | 1 - 3% |

| R&D for Compliance | - | 20 - 30% |

In summary, navigating the landscape of regulatory costs for engine businesses is crucial for any engine production business. With proper planning and a thorough understanding of the associated costs, businesses can effectively manage their engine manufacturing startup budget. For those looking for tailored financial strategies, resources like the Engine Manufacturing Financial Model can provide critical insights into budgeting and managing your initial investment in engine manufacturing.

Technology and Software Investments

When embarking on the journey of establishing an engine manufacturing company, one of the most critical budgetary considerations is the investment in technology and software. These investments play a pivotal role in ensuring streamlined operations, optimizing production processes, and maintaining competitiveness in the market.

The startup expenses for engine manufacturers related to technology can vary widely based on the scale and scope of the operations. On average, an initial investment in technology can range from $50,000 to $200,000 or more, depending on the level of automation and the type of software solutions adopted.

| Technology Type | Estimated Cost | Benefits |

|---|---|---|

| CAD Software | $10,000 - $30,000 | Enhanced design capabilities and reduced time-to-market. |

| Manufacturing Execution Systems (MES) | $20,000 - $50,000 | Real-time monitoring and control of production processes. |

| Enterprise Resource Planning (ERP) Systems | $30,000 - $100,000 | Improved resource management and integrated business processes. |

Investing in advanced machinery and engine manufacturing equipment that incorporates IoT (Internet of Things) capabilities can significantly improve efficiency and reduce downtime. The costs of machinery in engine production may range from $200,000 to $1,000,000, depending on the technology and automation level employed.

Tips for Cost-effective Solutions

- Consider open-source software solutions to minimize initial costs while ensuring adequate functionality.

- Invest in scalable technology that can grow with your business, rather than oversized systems that may lead to unnecessary expenses.

- Look for technological partnerships or collaborations that can provide reduced rates on software licenses and equipment.

Moreover, the costs to start an engine manufacturing company can include significant software licensing fees, which may account for a substantial portion of your initial budget. Licensing requirements for engine manufacturers can vary greatly, and it’s essential to budget for these expenses accordingly. For instance, licensing costs can range from $5,000 to $15,000 annually, depending on the software provider.

Additionally, funding for engine manufacturing startups may be accessible through various avenues, including venture capital, government grants, and industry partnerships. Allocating a portion of your initial budget to software and technology not only supports the production process but also aids in achieving compliance with regulatory standards, ultimately impacting your overall operational costs.

In summary, careful planning and budgeting for technology and software investments are essential when determining the engine production business expenses. By strategically allocating resources, you can maximize efficiency and position your engine manufacturing company for long-term success. For detailed insights on financial planning tailored for engine manufacturers, consider exploring [this financial model](https://financialmodeltemplates.com/products/engine-manufacturing-financial-model) to better understand your startup costs and requirements.

Marketing and Branding Expenses

In the engine manufacturing industry, effective marketing and branding are crucial for establishing a strong market presence and attracting clients, especially given the competitive landscape. For Engine Innovations Corp, allocating a substantial budget for marketing and branding is essential to communicate the innovative solutions offered and to highlight the environmentally friendly aspects of the products.

The typical startup expenses for engine manufacturers can be broken down into several key components:

- Brand Development: Developing a unique brand identity, including logo design, brand messaging, and overall aesthetic that reflects the company's commitment to innovation and sustainability.

- Website Development: Creating a professional and functional website to showcase products, services, and the company’s capabilities. A well-designed website can cost anywhere from $5,000 to $15,000 depending on complexity.

- Digital Marketing: Incorporating strategies such as search engine optimization (SEO), pay-per-click (PPC) advertising, and social media campaigns aimed at reaching potential customers in the automotive and aerospace sectors.

- Content Marketing: Producing valuable content, such as blogs, webinars, and white papers, to position the company as a thought leader in the engine manufacturing industry.

- Networking Events and Trade Shows: Participating in industry trade shows and networking events to showcase innovations and establish relationships is another essential expense. Budgeting approximately $10,000 to $50,000 for travel, booths, and marketing materials is advisable.

- Public Relations: Engaging a PR firm to help with media outreach can be invaluable. This could range from $1,000 to $5,000 monthly, depending on the services offered.

| Expense Type | Estimated Cost | Notes |

|---|---|---|

| Brand Development | $3,000 - $10,000 | Includes logo and branding materials. |

| Website Development | $5,000 - $15,000 | Cost varies with functionality and design. |

| Digital Marketing | $1,000 - $5,000/month | Initial setup and ongoing costs. |

| Networking Events | $10,000 - $50,000 | Budget for multiple events. |

Overall, it is estimated that marketing and branding can consume approximately 10% to 20% of the total initial investment in engine manufacturing. This allocation is vital for ensuring the startup stands out in a crowded marketplace and connects with target audiences effectively.

Tips for Budgeting Marketing and Branding Costs

- Start small: Focus on cost-effective marketing strategies like social media and content marketing to build brand awareness without large expenditures.

- Utilize analytics: Track the effectiveness of marketing campaigns using analytics tools to refine strategies and avoid wasted spending.

- Leverage partnerships: Form alliances with other businesses to co-market and share resources, reducing overall marketing costs.

As you plan your engine manufacturing company investment, remember that the marketing costs for engine manufacturers are not merely an expense but an essential part of building a sustainable business. Investing wisely in marketing will help differentiate your products, attract a loyal customer base, and position Engine Innovations Corp for long-term success in the highly competitive engine manufacturing market.

Initial Recruitment and Training Costs

When embarking on the journey to establish an engine manufacturing company, one must account for initial recruitment and training costs as a significant portion of the startup expenses for engine manufacturers. The success of your venture hinges on assembling a skilled workforce that can navigate the complexities of engine production while adhering to stringent regulatory standards.

Recruitment costs can vary widely based on the size of your operation and the level of expertise required. On average, expenses may include:

- Job Advertising: Costs associated with posting job vacancies on various platforms typically range from $200 to $1,000 per position.

- Recruitment Agency Fees: If leveraging an agency, expect to pay around 15-25% of the hired employee’s first-year salary.

- Interview and Assessment Costs: This could include travel reimbursements, testing materials, and other candidate-related expenses, averaging $500 to $2,000.

Once your team is onboard, training costs are another critical consideration. Training programs are essential for ensuring that your employees are adept in the latest technologies and manufacturing processes. The training budget generally encompasses:

- Initial Training Programs: Depending on the complexity of the manufacturing techniques, initial training could cost between $1,000 and $5,000 per employee.

- Ongoing Education: Regular training sessions and workshops are vital for maintaining skill levels, averaging about $1,500 annually per employee.

- Certification and Compliance Training: For roles requiring specific qualifications, expect to invest another $500 to $2,000 per employee.

In total, initial recruitment and training can contribute significantly to your engine manufacturing startup budget. To give you a clearer picture, here’s a table illustrating a potential breakdown of these costs:

| Cost Category | Estimated Minimum Cost | Estimated Maximum Cost |

|---|---|---|

| Job Advertising | $200 | $1,000 |

| Recruitment Agency Fees | $3,000 (based on $20,000 salary) | $5,000 (based on $25,000 salary) |

| Interview and Assessment Costs | $500 | $2,000 |

| Initial Training | $1,000 | $5,000 |

| Ongoing Education (Annual) | $1,500 | $1,500 |

| Certification Training | $500 | $2,000 |

| Total Estimated Costs | $6,700 | $16,500 |

Tips for Reducing Recruitment and Training Costs

- Utilize digital recruitment platforms to reach a wider audience at minimal costs.

- Consider internships or apprenticeships as a way to train potential employees at a lower expense.

- Leverage employee referral programs to attract qualified candidates without the hefty recruitment agency fees.

Ultimately, carefully budgeting for recruitment and training is essential for minimizing costs to start an engine manufacturing company. Investing in a knowledgeable workforce will not only contribute to immediate productivity but also foster long-term growth as your engine production business scales. For those looking to dive deeper into the financial aspects of starting an engine manufacturing business, consider checking out resources on engine manufacturing financial models.

Insurance and Legal Fees

Starting an engine manufacturing company like Engine Innovations Corp involves various startup expenses that ensure you comply with legal requirements and protect your business. Among these, insurance and legal fees are crucial components of your budget. Neglecting these expenses can lead to severe financial implications down the line.

Insurance costs can vary widely based on the size and scope of your operation, ranging from $5,000 to $20,000 annually. Key types of insurance you should consider include:

- General liability insurance

- Property insurance

- Workers' compensation insurance

- Product liability insurance

To ensure you are adequately covered, it's important to assess the specific risks associated with engine manufacturing. This includes potential liabilities stemming from manufacturing defects or workplace injuries. Conducting a comprehensive risk assessment can help determine the extent of coverage you require.

Legal fees are another significant part of the engine manufacturing startup costs. These can encompass various aspects such as:

- Consultation fees for legal advice on business structure and compliance

- Costs associated with intellectual property registration, especially if you are developing innovative engine technologies

- Preparation and filing of licensing and regulatory documents, which are vital for operating within industry standards

In total, businesses can expect to allocate anywhere from $10,000 to $50,000 for initial legal fees, depending on the complexity of their operations and the geographic regions in which they are based. For an efficient budget plan, consider the following:

Tips for Managing Insurance and Legal Expenses

- Shop around for insurance providers to find competitive rates.

- Consult with a legal expert specialized in manufacturing or industrial law for accurate estimates.

- Consider bundling insurance policies to reduce overall costs.

Regulatory compliance is also a key consideration when budgeting for engine manufacturing company investment. Depending on your location, regulatory costs for engine businesses can include adherence to environmental standards, safety regulations, and local zoning laws. All these factors must be accounted for in your financial projections.

| Expense Type | Estimated Cost Range | Notes |

|---|---|---|

| Insurance | $5,000 - $20,000 | Varies by coverage and business size |

| Legal Fees | $10,000 - $50,000 | Complexity increases costs |

| Regulatory Compliance | Variable | Dependent on local laws |

In conclusion, the financial plan for your engine manufacturing company must prioritize these key expenses to ensure a stable launch. For a deeper dive into financial planning for your engine manufacturing startup, consider exploring resources that offer detailed financial models tailored specifically for the engine manufacturing industry. Click here to learn more.