Related Blogs

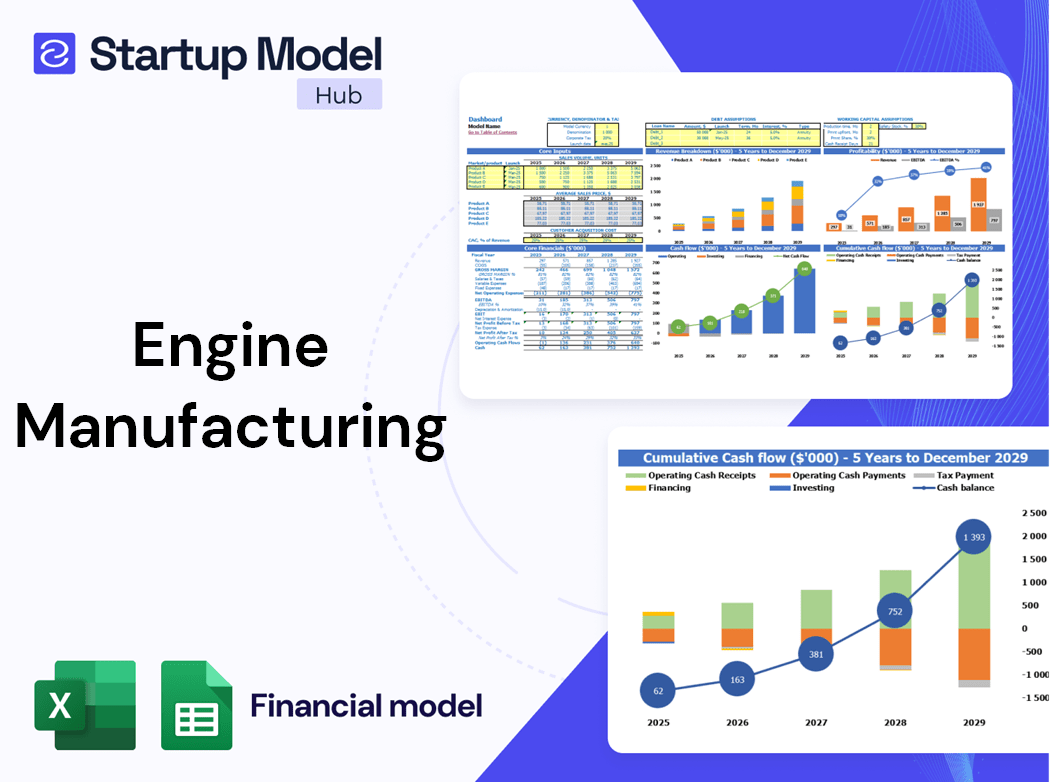

Are you ready to unlock the secrets to maximizing your profits in the engine manufacturing sector? Discover nine innovative strategies that can elevate your business to new heights, from enhancing operational efficiency to leveraging cutting-edge technology. Don't miss out on the opportunity to transform your financial outlook; explore our comprehensive business plan at Engine Manufacturing Financial Model for actionable insights.

What Is The Profit Potential Of Engine Innovations Corp?

Engine Innovations Corp is strategically positioned to harness the burgeoning profit potential within the engine manufacturing sector. With the global market for advanced engine technologies projected to reach **$300 billion** by 2027, driven by increasing demand for **eco-friendly solutions** and heightened regulatory standards, the opportunity for profit expansion is substantial.

By focusing on sustainable engine solutions, Engine Innovations Corp can tap into a growing consumer base that values **environmental responsibility**. Reports indicate that **70%** of consumers prefer brands that demonstrate sustainability, making this a lucrative avenue for growth. Moreover, utilizing **cutting-edge engine technologies** can enhance performance and efficiency, further appealing to automotive and aerospace clients.

The potential for **engine manufacturing profits** is further magnified through strategic investments in research and development. Companies that allocate at least **5% of their revenue** to R&D see up to a **20% increase** in market share over five years. This financial strategy allows Engine Innovations Corp to lead innovations while also solidifying its competitive edge.

However, to fully realize this profit potential, Engine Innovations Corp must also navigate key challenges in engine manufacturing, such as supply chain optimization and the integration of **lean manufacturing practices**. Advanced analytics can provide **market insights**, enabling the company to adjust strategies effectively and reduce waste by as much as **30%**, which significantly boosts operational efficiency.

Tips for Maximizing Profit Potential

- Invest in **predictive analytics** to foresee market trends and adjust production accordingly.

- Develop **strategic partnerships** to share resources and reduce costs in R&D efforts.

- Prioritize **customer customization** to differentiate products and increase sales opportunities.

Furthermore, expanding into emerging markets can provide Engine Innovations Corp with new revenue streams. As regions such as Asia-Pacific anticipate a **compound annual growth rate (CAGR)** of **7.5%** in the automotive sector, establishing a presence in these markets can yield significant returns.

Overall, the profit potential of Engine Innovations Corp hinges on its ability to innovate while maintaining operational excellence and strategically navigating industry challenges. By leveraging effective **sales growth strategies**, and aligning with consumer preferences for sustainable practices, the possibilities for increased profitability in the engine manufacturing space are not just promising; they are transformative. For a deeper understanding of the profitability landscape in engine manufacturing, visit this informative article on engine manufacturing profitability here.

What Are The Key Challenges And Opportunities For Engine Innovations Corp?

Engine Innovations Corp is poised at a pivotal moment in the engine manufacturing industry, facing both significant challenges and promising opportunities. The demand for sustainable engine solutions has surged, driven by increasing environmental regulations and consumer preferences for eco-friendly products. However, navigating the complexities of modern manufacturing can present hurdles that must be addressed effectively.

One of the primary challenges in engine manufacturing is the high cost of research and development (R&D) for cutting-edge engine technologies. Companies must invest significantly to innovate while ensuring that these advancements align with market needs and compliance standards. According to industry reports, R&D expenditures in the automotive sector can range from 5% to 10% of total revenue, indicating a substantial financial commitment required to stay competitive.

Additionally, there are persistent challenges in supply chain optimization. The engine industry relies heavily on a complex network of suppliers for high-quality materials. Disruptions, whether from geopolitical issues or global pandemics, can severely impact production timelines and costs. The need for effective supply chain management is critical to minimizing disruptions and maximizing operational efficiency.

However, opportunities abound for Engine Innovations Corp. The shift towards eco-friendly engine manufacturing provides a substantial market potential. Companies that can successfully innovate and deliver sustainable engine solutions could capture a significant share of the market, with the global green engine market projected to grow by 15% annually through 2030.

Furthermore, by embracing lean manufacturing practices, Engine Innovations Corp can achieve waste reduction and improved margins. Implementing these practices can lead to cost savings of up to 30% in certain operational areas, enhancing profit margins substantially.

Tips for Addressing Challenges and Seizing Opportunities

- Prioritize investment in R&D to stay ahead of technological trends.

- Establish robust relationships with suppliers to mitigate supply chain risks.

- Adopt lean manufacturing principles to streamline production and reduce costs.

- Conduct regular market analyses using advanced data analytics to identify growth areas.

The landscape for Engine Innovations Corp is undoubtedly competitive, but by strategically addressing challenges such as high R&D costs and supply chain inefficiencies, while simultaneously capitalizing on opportunities in the sustainable engine sector, the company can enhance its engine manufacturing profits and establish itself as a leader in the industry.

What Clear And Measurable Goals Should Be Set For Engine Innovations Corp?

Setting clear and measurable goals is essential for maximizing engine manufacturing profits at Engine Innovations Corp. Goals should align with the company's vision of delivering innovative, sustainable engine solutions while also addressing market demands and operational efficiencies.

To evaluate and track progress effectively, Engine Innovations Corp should consider the following key goals:

- Increase Annual Revenue by 20% Over the Next Three Years: Implement robust sales growth strategies for engine products targeting automotive and aerospace sectors.

- Achieve a 15% Reduction in Production Costs: Utilizing lean manufacturing benefits to enhance operational efficiency in engine manufacturing.

- Launch Three New Eco-Friendly Engine Models in Five Years: Focus on sustainable engine solutions leveraging cutting-edge technologies.

- Improve Customer Satisfaction Ratings to 90%: Engaging in customization in engine production based on client specifications.

- Expand into Two Emerging Markets by 2025: Identify and penetrate growing markets for engine manufacturers to increase revenue streams.

- Reduce Manufacturing Waste by 25%: Implement waste reduction in manufacturing processes to enhance overall efficiency.

Tips for Setting Effective Goals:

- Utilize Data Analytics: Leverage market insights analytics engine to set realistic benchmarks and KPIs.

- Review Regularly: Set quarterly reviews to assess progress against goals, allowing for adjustments based on performance data.

- Engage Employees: Involve team members in goal-setting to foster ownership and commitment towards reaching targets.

According to industry data, manufacturers that implement structured goal-setting frameworks can see up to a 25% increase in productivity (source: Financial Model Templates), underscoring the importance of establishing clear and measurable goals within Engine Innovations Corp.

Furthermore, financial planning for engine manufacturing companies should incorporate flexible strategies that allow for adjustments in response to shifts in market dynamics and operational challenges. This adaptability will drive better performance and ultimately increase profits in the competitive engine manufacturing landscape.

How Can Operational Efficiency Be Optimized For Engine Innovations Corp?

Operational efficiency is crucial for maximizing engine manufacturing profits, especially in a competitive landscape. For Engine Innovations Corp, optimizing operations can lead to significant reductions in cost and time while enhancing product quality. Here are key strategies:

- Lean Manufacturing Practices: Implementing lean manufacturing can reduce waste by up to 30%, as reported in various case studies within the industry. Streamlining processes and focusing on value-added activities ensures that every step in production contributes to the end product.

- Supply Chain Optimization: Integrating effective supply chain strategies can lead to a reduction in inventory costs by 15-25%. By leveraging technology and analytics, Engine Innovations Corp can enhance demand forecasting and inventory management, ensuring that materials are available when needed without overstocking.

- Advanced Data Analytics: Utilizing market insights analytics can provide real-time data on production efficiency, enabling informed decision-making. Companies that adopt data-driven processes can experience a 10-20% increase in productivity.

- Customization in Production: Tailoring engines to meet specific client needs not only enhances customer satisfaction but also contributes to operational efficiency. When production lines can adapt quickly to new specifications, lead times decrease, fostering better client relationships and potential sales growth.

- Emphasis on Training: Investing in employee training can improve operational efficiency. Well-trained staff are more adept at identifying inefficiencies and implementing best practices, possibly reducing operational errors by up to 40%.

Tips to Optimize Operational Efficiency

- Conduct regular audits of production processes to identify bottlenecks and areas for improvement.

- Incorporate automation technologies where feasible to minimize manual errors and enhance speed.

- Foster a culture of continuous improvement among employees, encouraging them to suggest enhancements.

By implementing these strategies, Engine Innovations Corp can significantly improve its operational efficiency, leading to increased profits in the engine business. Moreover, with the shift towards sustainable engine solutions, focusing on eco-friendly practices while optimizing operations can fulfill both market demands and regulatory requirements.

It is essential to understand that challenges in engine manufacturing, such as fluctuating material costs and evolving regulatory standards, can impact operational efficiency. However, by continually refining processes and adapting to market needs, Engine Innovations Corp can remain competitive and profitable.

According to industry benchmarks, companies that prioritize operational efficiency tend to see an improvement in their financial planning for engine manufacturing companies, with higher profit margins and lower operational costs, leading to overall enhanced business resilience.

What Sales Strategies Can Drive Growth For Engine Innovations Corp?

To effectively increase profits in engine manufacturing, Engine Innovations Corp must adopt targeted sales strategies that leverage its innovative capabilities and sustainable solutions. By focusing on customer-centric approaches and creating a compelling value proposition, the company can enhance its market position and drive sales growth in a competitive landscape.

Understanding the Market Landscape

Engine Innovations Corp operates in a rapidly evolving industry where understanding market dynamics is crucial. A report by Financial Model Templates highlights that the global engine manufacturing market is projected to grow at a CAGR of 4.5% from 2021 to 2028, emphasizing the opportunities available for strategic market penetration.

Effective Sales Strategies

Implementing a mix of traditional and innovative sales strategies can significantly enhance the engine business's revenue potential. Key strategies include:

- Customer Education and Engagement: Conduct workshops and webinars to educate potential clients about the benefits of sustainable engine solutions. This positions Engine Innovations Corp as a thought leader in eco-friendly engine manufacturing.

- Leveraging Digital Marketing: Utilize digital marketing strategies, including SEO and targeted ads, to increase brand visibility and attract a broader audience.

- Customization Offerings: Focus on customization in engine production to meet specific client needs, enhancing customer satisfaction and loyalty.

- Referral Programs: Establish referral incentives for existing customers to encourage word-of-mouth marketing, which can lead to increased sales without significant marketing costs.

- Strategic Partnerships: Form alliances with key players in the automotive and aerospace sectors to tap into new client bases and enhance credibility.

- Utilizing Advanced Analytics: Implement market insights analytics to identify trends and customer preferences, allowing for more effective sales pitches and product offerings.

Tips for Implementing Sales Strategies

- Track Performance Metrics: Regularly analyze sales data to adapt strategies based on real-time market feedback.

- Invest in Sales Training: Equip your sales team with knowledge about cutting-edge engine technologies and industry regulations to enhance their effectiveness.

- Utilize Social Media: Engage potential clients through social media channels, providing information and updates on new sustainable engine solutions.

By focusing on these tailored sales growth strategies, Engine Innovations Corp can significantly increase profits in the engine manufacturing sector while reaffirming its commitment to sustainable and advanced engine technologies. Through a customer-focused approach and by capitalizing on emerging trends, the company is well-positioned to thrive amidst challenges in the engine manufacturing landscape.

What Are The Financial Strategies For Engine Innovations Corp?

In the competitive landscape of engine manufacturing, a well-structured financial strategy is crucial for maximizing engine manufacturing profits and ensuring long-term viability. Engine Innovations Corp must adopt a multi-faceted approach that focuses on cost management, revenue generation, and resource allocation to thrive in this dynamic market.

1. Cost Control and Reduction

Implementing stringent cost control measures can significantly enhance profit margins. Strategies may include:

- Conducting regular audits of operational expenses.

- Identifying areas for waste reduction in manufacturing processes.

- Leveraging technology for process automation to minimize labor costs.

2. Financial Planning and Forecasting

Effective financial planning is essential for the sustainability of Engine Innovations Corp. This involves:

- Creating detailed financial models to project revenues and expenses.

- Utilizing advanced analytics to understand market trends and adjust strategies accordingly.

- Incorporating sensitivity analyses to prepare for various market scenarios.

3. Investment in R&D

Investing in research and development is pivotal for maintaining a competitive edge. By focusing on cutting-edge engine technologies, the company can develop superior products that cater to the evolving needs of clients, thereby enhancing profitability.

4. Diversification of Revenue Streams

Engine Innovations Corp should explore diversification to mitigate risks associated with the engine manufacturing sector. Consider:

- Offering aftermarket services such as maintenance and upgrades.

- Expanding product lines to include sustainable engine solutions.

- Targeting emerging markets for engine manufacturers to tap into new customer bases.

5. Strategic Partnerships

Forming strategic partnerships in manufacturing can lead to shared resources and expanded market access. Collaborative ventures with suppliers or technology providers can lead to improved cost-efficiencies and innovation.

6. Pricing Strategy Optimization

Developing a robust pricing strategy is essential to maximize revenue. It should consider:

- Performing competitive analysis to ensure pricing aligns with market standards.

- Implementing dynamic pricing models based on demand and supply.

- Offering tiered pricing for different customer segments to enhance accessibility.

7. Effective Cash Flow Management

Maintaining healthy cash flow is critical for operational continuity. Engine Innovations Corp can:

- Implement real-time cash flow monitoring systems.

- Negotiate favorable payment terms with suppliers to improve liquidity.

- Streamline accounts receivable processes to minimize delays in payment.

8. Leverage Technology for Financial Insights

Utilizing data analytics to gain market insights can inform strategic decisions. By adopting financial management software, the company can:

- Track financial performance metrics efficiently.

- Analyze profitability by product line to focus on high-margin offerings.

9. Regular Financial Assessments

Conducting regular assessments of financial health can help ensure that Engine Innovations Corp stays on track with its goals. These assessments should focus on:

- Reviewing key performance indicators related to financial strategies for engine manufacturers.

- Adjusting strategies based on performance data and market conditions.

Tips for Financial Strategy Effectiveness

- Always align financial strategies with your overall business goals to ensure cohesion.

- Regularly update financial models to reflect changes in the market landscape.

- Engage cross-functional teams when developing financial strategies to gain diverse perspectives.

By implementing these financial strategies, Engine Innovations Corp can position itself strategically within the engine manufacturing sector, ensuring increased profitability and sustained growth in the face of industry challenges. For additional insights, businesses can refer to resources like this guide on engine manufacturing profitability.

What Are The Strategies For Engine Innovations Corp?

To maximize engine manufacturing profits and position Engine Innovations Corp as a leader in the industry, a multifaceted strategy that encompasses innovation, operational efficiency, and market expansion is essential. The following strategies can be employed:

Develop Sustainable And Eco-Friendly Engine Solutions

As environmental regulations tighten, prioritizing sustainable engine solutions will not only enhance compliance but also appeal to a growing market segment that values eco-friendly products. For instance, the demand for eco-friendly engine manufacturing solutions is projected to grow, making this a vital strategy.

Invest In Research And Development For Cutting-Edge Technologies

Allocating funds towards research and development in the engine industry will spur innovation. Engaging in R&D can lead to the creation of high-performance engines that meet modern demands, increasing competitiveness and profit margins.

Enhance Supply Chain Management For Cost Efficiency

Improving supply chain optimization in the engine industry by adopting advanced logistics practices can significantly reduce production costs. Streamlined operations allow for better resource allocation and increased profit margins.

Implement Lean Manufacturing Practices To Reduce Waste

Embracing lean manufacturing benefits can lead to substantial waste reduction. By focusing on waste minimization, Engine Innovations Corp can enhance overall productivity and thus increase profits in the engine manufacturing sector.

Form Strategic Partnerships With Key Industry Players

Building strategic partnerships in manufacturing can provide access to new markets, technologies, and resources. Collaboration with established players can foster innovation and accelerate growth, thus enhancing profitability.

Utilize Advanced Data Analytics For Market Insights

Leveraging market insights analytics engine will allow the company to make data-driven decisions, identifying trends and customer preferences quickly. This strategic move can lead to targeted marketing and improved sales growth.

Focus On Customization To Meet Client Specifications

By emphasizing customization in engine production, Engine Innovations Corp can cater to unique client needs, enhancing customer satisfaction and driving repeat business, further boosting profitability.

Expand Into Emerging Markets With Growth Potential

Emerging markets present untapped opportunities for growth. By identifying and entering these markets, Engine Innovations Corp can significantly increase its customer base, driving sales growth strategies engine and overall revenues.

Leverage Digital Marketing To Increase Brand Awareness

Employing effective digital marketing strategies for manufacturing can enhance visibility and attract potential clients. A robust online presence allows for better engagement and can translate to increased sales.

Tips for Effective Implementation

- Regularly assess the effectiveness of each strategy through key performance indicators (KPIs) to adapt as needed.

By incorporating these strategies, Engine Innovations Corp can significantly enhance its profitability and establish a strong presence in the competitive engine manufacturing landscape. According to industry insights, companies that focus on innovation and sustainability are more likely to see a return on investment within a shorter timeframe. Investing in such areas could yield an improvement of up to 20%-30% in profit margins over five years.

Develop Sustainable And Eco-Friendly Engine Solutions

As the global economy shifts towards sustainability, Engine Innovations Corp recognizes the immense profit potential of developing sustainable and eco-friendly engine solutions. With increasing environmental regulations and consumer demand for greener technologies, the engine manufacturing industry is at a pivotal crossroads. By embracing eco-friendly practices, Engine Innovations Corp can not only comply with regulations but also enhance its brand reputation and customer loyalty.

Adopting sustainable engine technologies can significantly increase profits while minimizing negative environmental impacts. Engine Innovations Corp aims to lead in this area by focusing on:

- Utilizing renewable energy sources during production.

- Developing engines that run on alternative fuels, such as hydrogen and biofuels.

- Implementing lightweight, recyclable materials to reduce energy consumption during vehicle operation.

According to a recent study, companies investing in sustainable practices can see a up to 20% increase in operational efficiency and a subsequent 10-15% growth in profitability. These statistics affirm that committing to sustainable engine solutions not only benefits the environment but also bolsters the bottom line.

Tips for Implementing Sustainable Practices

- Conduct a sustainability audit of current manufacturing processes to identify areas for improvement.

- Invest in research and development to harness cutting-edge engine technologies that prioritize eco-friendliness.

- Develop partnerships with organizations focused on sustainability to share knowledge and innovate collaboratively.

To ensure that Engine Innovations Corp stays competitive in the evolving landscape of engine manufacturing, it is crucial to keep a close eye on market insights and analytics. By leveraging data, the company can identify emerging trends and consumer preferences in eco-friendly products, thereby tailoring its offerings accordingly.

| Sustainability Initiative | Projected Cost Savings | Estimated Profit Increase |

|---|---|---|

| Alternative Fuel Development | $500,000 per year | 15% |

| Recyclable Materials Introduction | $300,000 per year | 10% |

| Energy Efficiency Improvements | $200,000 per year | 8% |

By pursuing these sustainable initiatives, Engine Innovations Corp not only aligns with global sustainability goals but also positions itself as a leader in the engine manufacturing industry. Companies that prioritize eco-friendly engine solutions are better equipped to navigate the challenges in engine manufacturing and tap into emerging markets with a strong demand for green technologies.

Moreover, emphasizing sustainable practices can open doors to new customer bases and attract environmentally conscious consumers, ultimately driving sales growth strategies for the engine sector. The profits gained from implementing these innovative solutions can foster long-term success and resilience in a rapidly evolving industry.

For those interested in maximizing their potential in engine manufacturing, utilizing effective financial strategies for engine manufacturers and ensuring operational efficiency in engine production will be key to unlocking increased profits. More insights on financial strategies specific to engine manufacturing can be found at this link.

Invest In Research And Development For Cutting-Edge Technologies

Investing in research and development (R&D) is crucial for Engine Innovations Corp to establish a strong foothold in the competitive landscape of engine manufacturing. The development of cutting-edge engine technologies not only enhances the profit potential of the company but also positions it as a leader in sustainable and innovative solutions.

According to recent industry reports, companies that prioritize R&D grow 60% faster than those that do not. In the context of engine manufacturing, this means that by focusing on advanced technologies such as eco-friendly engine solutions, Engine Innovations Corp can meet the rising demand for compliance with stringent environmental regulations while boosting operational efficiency.

Here are several key areas where R&D investment can significantly impact profit margins:

- Advanced Materials Research: Developing lightweight yet durable materials can improve engine performance and fuel efficiency, directly influencing customer satisfaction and retention.

- Hybrid and Electric Technologies: Investing in alternative fuel engines will allow Engine Innovations Corp to tap into emerging markets, as demand for hybrid and electric vehicles increases.

- AI and Automation Integration: Implementing AI-driven solutions can streamline manufacturing processes, reducing costs and waste, thereby improving operational efficiency in engine production.

Tips for Effective R&D Investment

- Establish partnerships with universities and research institutions to leverage academic expertise.

- Focus on customer feedback to guide R&D priorities, ensuring that developments meet market needs.

- Allocate a specific percentage of profits back into R&D, ideally between 10-15%, to maintain continuous innovation.

Moreover, utilizing advanced data analytics can provide key market insights that guide R&D efforts, ensuring that investments align with consumer demands. For example, data-driven insights indicate that reducing emissions by even 10% can increase market share significantly in environmentally conscious segments.

When examining real-life case studies, companies like Tesla illustrate the success associated with substantial R&D investment, which resulted in a 45% increase in revenue year-over-year. This serves as a vital benchmark for Engine Innovations Corp when considering the potential returns of dedicated R&D funding.

With the global engine manufacturing industry projected to grow by 5% annually, focusing on R&D not only enhances Engine Innovations Corp’s offerings but also positions it strategically for future growth. By aligning product development with market trends, the company can maximize sales growth strategies while reinforcing its commitment to sustainability.

To support these initiatives, Engine Innovations Corp should regularly reassess its R&D strategies and objectives, ensuring they remain ahead of market trends and technological advancements. By doing so, they can enhance their competitive edge and increase profits within the dynamic landscape of engine manufacturing.

| Investment Type | Expected ROI | Duration |

| Advanced Materials Research | 25% over 5 years | 2-3 years |

| Hybrid Technologies | 40% over 7 years | 3-5 years |

| AI Integration | 30% over 5 years | 1-2 years |

By implementing these targeted R&D strategies, Engine Innovations Corp can significantly enhance its engine manufacturing profits and establish itself as an innovator in the industry. For a detailed financial framework to support these initiatives, visit this link.

Enhance Supply Chain Management For Cost Efficiency

To increase profits in the engine manufacturing sector, particularly for a forward-thinking company like Engine Innovations Corp, optimizing supply chain management is crucial. A well-structured supply chain not only reduces costs but enhances overall operational efficiency, which is vital in maintaining competitiveness in the dynamic engine industry.

In the engine manufacturing business, where profit margins can be slim, even the slightest optimization in supply chain processes can lead to substantial savings. By focusing on supply chain optimization, Engine Innovations Corp can achieve reductions in lead times, costs, and waste, ultimately improving its engine manufacturing profits.

Here are some effective strategies to enhance supply chain management:

- Supplier Relationship Management: Building strong relationships with suppliers can lead to better terms, pricing, and reliability. Establishing long-term partnerships often results in bulk purchasing agreements, which can significantly lower costs.

- Inventory Management: Implementing just-in-time (JIT) inventory systems reduces holding costs and minimizes waste. By ensuring that inventory levels match production schedules, Engine Innovations Corp can enhance operational efficiency.

- Technology Integration: Utilizing advanced technologies such as ERP systems can streamline supply chain processes. This integration allows for real-time tracking and data analysis, enabling proactive decision-making.

- Logistics Optimization: Analyzing and improving transportation routes and methods can decrease shipping times and costs. The use of data analytics can uncover inefficiencies in current logistics strategies.

- Collaborative Planning: Engaging in collaborative forecasting and demand planning with key partners helps to align production schedules and inventory levels with actual market demand.

To illustrate the potential impact of these strategies, consider the following cost-saving opportunities:

| Strategy | Estimated Cost Savings | Impact on Operational Efficiency |

|---|---|---|

| Supplier Negotiations | 10-15% savings | Improved material availability |

| Just-In-Time Inventory | 20-30% reduction in holding costs | Increased cash flow and space optimization |

| Logistics Optimization | 15-25% decrease in transportation costs | Faster delivery times |

Tips for Effective Supply Chain Management

- Regularly assess supplier performance to ensure they meet quality and delivery standards.

- Invest in training employees on supply chain strategies and technologies.

- Utilize market insights analytics to forecast demand accurately.

By focusing on these key areas, Engine Innovations Corp can effectively enhance supply chain management for cost efficiency. In the context of engine manufacturing, where challenges are prevalent and competition is fierce, these measures can significantly contribute to improved engine manufacturing profits. The implementation of sound supply chain strategies will not only streamline operations but also position the company for future growth in a rapidly evolving marketplace.

For a deeper dive into financial planning tailored specifically to the engine manufacturing sector, Engine Innovations Corp can explore detailed models and strategies at this link.

Implement Lean Manufacturing Practices To Reduce Waste

Lean manufacturing has emerged as a powerful methodology that not only optimizes operational efficiency but also significantly enhances engine manufacturing profits. By prioritizing waste reduction, Engine Innovations Corp can channel its resources more effectively, thereby allowing for increased profitability and sustainable growth.

At its core, lean manufacturing focuses on eliminating non-value-added activities, streamlining production processes, and enhancing product quality. This approach can lead to substantial reductions in costs, improving the profit potential of engine innovations through several key practices:

- Value Stream Mapping: This technique helps identify all the steps in a process and discern which add value and which do not, allowing for targeted improvements.

- Continuous Improvement (Kaizen): Encouraging a culture of ongoing, incremental improvement ensures that efficiency is always being sought.

- Just-In-Time (JIT) Production: By producing only what is needed when it is needed, Engine Innovations can reduce inventory costs and minimize waste.

- Standardized Work Processes: Creating standardized methods for operations reduces variability, leading to improved quality and faster production times.

- Employee Empowerment: Engaging employees in decision-making fosters a sense of ownership and encourages innovative solutions to reduce waste.

Implementing these practices can deliver measurable results. For example, companies that have adopted lean manufacturing techniques have reported up to a 30% reduction in production costs and a 25% increase in productivity. These statistics demonstrate how adopting a lean approach can fundamentally alter the trajectory of an engine manufacturing business.

To set a benchmark, consider the following statistical insights:

| Metric | Before Lean Implementation | After Lean Implementation |

|---|---|---|

| Production Costs (% of revenue) | 60% | 43% |

| Defect Rate (% of production) | 8% | 2% |

| Employee Efficiency (units per hour) | 10 | 15 |

Moreover, the benefits of lean manufacturing align remarkably well with the sustainable vision of Engine Innovations Corp. By producing eco-friendly engines efficiently, the company not only complies with modern regulations but also appeals to a growing market for sustainable engine solutions.

Tips to Optimize Lean Practices in Engine Manufacturing

- Conduct regular training sessions for employees to keep them updated on lean principles and practices.

- Utilize advanced data analytics to monitor performance metrics and identify areas for improvement.

- Engage in regular reviews of operational processes to ensure alignment with lean manufacturing goals.

As Engine Innovations Corp continues to embrace lean manufacturing, it is crucial to also assess the financial strategies for engine manufacturers. Maintaining a balance between optimizing operations and ensuring financial health will enable a robust roadmap towards increased profitability in the engine business strategies.

Incorporating lean practices is not merely a choice but a necessity for businesses aiming to survive and thrive in the competitive landscape of engine manufacturing. For further insights and robust financial modeling that can support these initiatives, visit this link. There, you'll find tools designed to facilitate planning and analysis, ensuring that your strategies align with the best practices in the industry.

Form Strategic Partnerships With Key Industry Players

In the competitive landscape of engine manufacturing, forming strategic partnerships with key players in the industry is essential for optimizing operational efficiency and driving engine manufacturing profits. These collaborations can open doors to new markets, foster innovation, and create synergies that enhance productivity and sustainability. By aligning with renowned industry partners, Engine Innovations Corp can leverage shared resources to accelerate growth and improve its product offerings.

Several strategic partnerships can be particularly beneficial for Engine Innovations Corp, including:

- Collaboration with Technology Firms: Partnering with technology companies specializing in cutting-edge engine technologies can enhance innovation. For example, integrating advanced materials and processes can lead to the development of eco-friendly engine solutions, which are increasingly demanded by the market.

- Alliances with Research Institutions: Engaging with universities and research organizations can provide access to the latest research and development in the engine sector. This partnership can help in overcoming challenges in engine manufacturing and lead to breakthroughs that enhance profitability.

- Joint Ventures with Automotive and Aerospace Manufacturers: Forming joint ventures with established automotive and aerospace companies can lead to shared expertise and resources. This can facilitate entry into new markets and broaden product lines, thus increasing profitability.

According to recent studies, strategic partnerships can lead to a 25% increase in operational efficiency for manufacturing businesses. Furthermore, companies that engage in partnerships report a 30% boost in creativity and innovation, leading to enhanced product development and customer satisfaction.

| Partnership Type | Benefits | Potential ROI |

|---|---|---|

| Technology Firms | Access to advanced technologies and innovative materials | 20%-30% |

| Research Institutions | Enhanced R&D capabilities and quicker innovation | 15%-25% |

| Automotive/Aerospace Manufacturers | Market expansion through established networks | 25%-35% |

To maximize the impact of these partnerships, Engine Innovations Corp should adopt the following strategies:

Key Tips for Forming Strategic Partnerships

- Identify potential partners whose goals align with the company’s vision for sustainable engine solutions.

- Establish clear objectives and contribute equally to partnership efforts to ensure mutual benefits.

- Regularly assess the partnership outcomes to adapt strategies and enhance collaboration.

Additionally, the potential for increased sales growth strategies in the engine manufacturing industry can be amplified through these partnerships. For instance, partnering with companies known for strong distribution networks can facilitate access to new customer bases. Furthermore, companies that establish robust supply chain optimization in the engine industry through partnerships can reduce costs and improve responsiveness to market changes.

Overall, by forming strategic partnerships with key industry players, Engine Innovations Corp can enhance its market positioning and increase profits while staying ahead of industry challenges. Such collaborations not only enhance operational efficiency but also provide valuable market insights that can lead to innovative product offerings tailored to client specifications. Explore how to maximize your potential with strategic partnerships and learn more about effective financial strategies for engine manufacturers at Engine Innovations Corp Financial Model.

Utilize Advanced Data Analytics For Market Insights

In the competitive landscape of engine manufacturing, leveraging advanced data analytics is crucial for staying ahead. Engine Innovations Corp can harness these analytics to gain profound market insights that drive decision-making and increase profits.

By employing sophisticated analytics tools, the company can:

- Identify emerging trends in engine technologies that align with environmental regulations.

- Track customer preferences and behaviors, enhancing the customization of engine solutions.

- Optimize operational efficiency by analyzing production data to reduce waste and improve lean manufacturing practices.

- Assess supply chain performance, pinpointing inefficiencies that could impact the bottom line.

Statistical data shows that businesses employing data-driven strategies can achieve a profit increase of up to 5-10% annually. In the engine manufacturing sector, this translates into significant financial gains.

| Analytics Application | Potential Profit Impact (%) | Implementation Cost ($) |

|---|---|---|

| Trend Identification | 5% | 50,000 |

| Customer Behavior Tracking | 7% | 30,000 |

| Operational Efficiency Optimization | 10% | 40,000 |

Furthermore, data analytics can help Engine Innovations Corp evaluate the profit potential of new eco-friendly solutions. By analyzing market sentiment towards sustainable engine technologies, the company can align its research and development efforts with consumer demand, ensuring that it capitalizes on emerging opportunities.

With the engine industry increasingly focusing on sustainable engine solutions, predictive analytics can offer insights into future trends, helping manufacturers prepare and innovate ahead of the competition.

Tips for Implementing Advanced Data Analytics

- Invest in training staff to interpret data effectively, ensuring they can turn insights into actionable strategies.

- Utilize cloud-based analytics solutions for scalability and ease of access across the organization.

- Establish key performance indicators (KPIs) to measure the effectiveness of data-driven decisions.

Another vital aspect is forming strategic partnerships that allow for data sharing and collaboration. Collaborating with technology firms specializing in analytics can provide Engine Innovations Corp with cutting-edge tools without the need for substantial upfront investments.

Incorporating advanced data analytics into the operational framework will not only drive immediate gains but also set a foundation for sustained growth and profitability in the evolving landscape of engine manufacturing. With an eye on the future, Engine Innovations Corp can use these insights to navigate the complexities of the industry and take calculated risks that yield substantial rewards.

For those considering a comprehensive financial approach, additional resources such as the Engine Manufacturing Financial Model can provide tailored insights and strategies.

Focus On Customization To Meet Client Specifications

In the competitive realm of engine manufacturing, customization has emerged as a vital strategy for increasing profits. By tailoring engine solutions to the unique specifications of clients, Engine Innovations Corp can carve out a substantial market niche, meeting diverse demands that standard engine designs cannot fulfill.

Offering customized engine solutions not only enhances customer satisfaction but also fosters long-term relationships with clients, which can lead to repeat business and referrals. The ability to adapt to specific requirements—whether it be performance, fuel efficiency, or compliance with environmental regulations—positions Engine Innovations Corp as a leader in the industry.

Benefits of Customization in Engine Manufacturing

- Increased client satisfaction through tailored products.

- Higher margins due to premium pricing for customized solutions.

- Opportunity to enter niche markets with specialized needs.

- Strengthened client relationships fostering loyalty and repeated sales.

To effectively implement customization, Engine Innovations Corp should consider the following strategies:

- Invest in Advanced Manufacturing Technologies: Utilizing cutting-edge technologies such as 3D printing can support rapid prototyping and customization, significantly reducing lead times and costs associated with traditional manufacturing.

- Gather Client Feedback: Actively seek input from clients regarding their specific needs and preferences. This data will ensure that the engines produced align with market demand.

- Offer Modular Designs: Developing modular engine systems allows modifications based on client requirements, enabling versatility and enhanced performance.

Benchmarking Customization Strategies

| Customization Approach | Expected Profit Increase | Time to Market Reduction |

|---|---|---|

| Client-Specific Designs | 15-25% | 30% |

| Modular Engine Solutions | 20-30% | 25% |

| Rapid Prototyping | 10-20% | 40% |

Incorporating customization into the operational framework not only significantly impacts the profit potential of Engine Innovations Corp but also addresses the evolving needs of the market. According to recent studies, companies that embrace product customization report an average increase of 10-20% in customer retention rates, which is critical in today’s highly competitive engine manufacturing landscape.

As Engine Innovations Corp pursues its mission of delivering innovative and sustainable engine solutions, customization will act as a key driver in optimizing operational efficiency and enhancing overall profitability in the engine manufacturing sector.

For further insights and financial planning options, consider exploring this engine manufacturing financial model designed to support growing engine businesses.

Expand Into Emerging Markets With Growth Potential

For Engine Innovations Corp, expanding into emerging markets presents a significant opportunity to increase profits in the engine manufacturing sector. The global demand for engine solutions is shifting, with growing regions such as Southeast Asia, Africa, and South America becoming increasingly important. These markets offer untapped potential due to rising industrialization, urbanization, and a burgeoning middle class.

Emerging markets are not only seeking cutting-edge engine technologies but are also highly receptive to sustainable and eco-friendly engine solutions. According to a report by McKinsey, the global engine market in emerging economies is projected to grow by 7.5% annually, significantly outpacing mature markets.

To successfully penetrate these markets, Engine Innovations Corp can implement the following strategies:

Key Strategies for Expanding into Emerging Markets

- Conduct thorough market research to identify specific needs and preferences.

- Form strategic partnerships with local firms to facilitate entry and reduce market entry risks.

- Adapt products to meet local regulations and standards, ensuring compliance and appeal.

- Leverage digital marketing strategies to build brand awareness and engage potential clients.

- Ensure a robust supply chain optimization strategy to maintain cost efficiency while meeting demand.

The importance of customizing the product offerings cannot be overstated. Emerging markets often have unique demands, and the ability to provide tailored engine solutions can be a substantial differentiator. For instance, Engine Innovations Corp could consider developing engines that are optimized for local fuel types or climate conditions, enhancing their performance and efficiency in specific environments.

| Region | Projected Annual Growth Rate | Key Industries |

|---|---|---|

| Southeast Asia | 7% - 9% | Automotive, Aerospace |

| Africa | 6% - 8% | Agriculture, Mining |

| South America | 5% - 7% | Aerospace, Automotive |

Moreover, establishing a local presence in these regions can significantly enhance operational efficiency and customer service. This can be achieved through:

- Setting up regional distribution centers to minimize shipping costs and delivery times.

- Hiring local talent who understand the market dynamics and customer preferences.

- Offering training programs for local partners and clients to increase product adaptability.

It is also crucial to be vigilant about the challenges in engine manufacturing within these emerging markets. Issues such as regulatory compliance, competition from local manufacturers, and fluctuating currency exchange rates can pose risks. Therefore, Engine Innovations Corp should incorporate comprehensive financial strategies for engine manufacturers that can mitigate these risks while fostering growth.

By focusing on these strategies and leveraging the profit potential in emerging markets, Engine Innovations Corp can significantly enhance its market footprint and operational efficiency in the global engine manufacturing arena. For further guidance on effective financial planning and operational strategies, consult detailed resources available at Engine Manufacturing Financial Model.

Leverage Digital Marketing To Increase Brand Awareness

In the highly competitive landscape of engine manufacturing, leveraging digital marketing strategies can significantly enhance brand awareness and drive engine manufacturing profits. As industry demands shift towards innovation and sustainability,

Digital marketing provides tools that facilitate targeted outreach, enabling

Key components of a successful digital marketing strategy for

- Content Marketing: Develop insightful content that focuses on cutting-edge engine technologies and eco-friendly engine manufacturing. This can position the brand as an expert in the field.

- Search Engine Optimization (SEO): Optimize the website and blog content to rank higher in search results relevant to engine innovations profit potential and challenges in engine manufacturing.

- Social Media Engagement: Use platforms like LinkedIn and Twitter to share updates, insights, and industry news, building a community of followers that resonate with

's mission. - Email Marketing: Send newsletters and updates to nurture leads and keep existing customers informed about new products and innovations.

Incorporating data analytics to assess the effectiveness of these strategies is crucial. By utilizing tools that provide market insights analytics,

Tips for Effective Digital Marketing in Engine Manufacturing

- Invest in a user-friendly website that showcases customization in engine production and highlights sustainability efforts.

- Engage in pay-per-click advertising to target specific segments within the engine manufacturing market.

- Utilize video content to demonstrate the manufacturing process and the benefits of sustainable engine solutions.

The effectiveness of these strategies can be benchmarked against industry standards. For example, businesses that actively engage in digital marketing see an average growth rate of 2.8 times faster than those who do not. Furthermore, companies that prioritize content marketing can experience conversion rates as high as 6 times better than traditional marketing methods.

| Digital Marketing Component | Potential Impact on Brand Awareness | Cost-Effectiveness |

|---|---|---|

| Content Marketing | Increases traffic to site by up to 55% | Cost-effective, 62% less than traditional marketing |

| SEO | Can lead to 50% more organic searches | High ROI, with $44 for every $1 spent |

| Social Media Engagement | Boosts brand recognition by 80% | Low-cost entry with high reach potential |

By employing these strategies effectively,

For detailed financial planning and projections related to engine manufacturing, explore this comprehensive financial model that can help in strategizing for optimal growth and sustainability in the market.