Related Blogs

Are you dreaming of launching your own engine manufacturing business but feeling overwhelmed by the complexities involved? Fear not! In just 9 essential steps, you can navigate the process from conception to execution with clarity and confidence. Whether you're starting from scratch or seeking a detailed business plan, discover practical insights and resources to set you on the path to success by exploring this comprehensive checklist: business plan.

How Do I Open An Engine Manufacturing Company With No Experience?

Starting an engine manufacturing business without prior experience may seem daunting, but it is entirely feasible with the right approach. The key lies in understanding the industry and leveraging available resources effectively. Here are some practical steps to consider:

Leverage Educational Resources

- Invest in online courses or workshops focused on manufacturing technologies and business management specific to the engine industry.

- Attend industry seminars and meetups to learn from experts and network with potential partners or mentors.

Engaging with professionals in the field can provide insights into engine component supply chain management and advanced manufacturing technology. Additionally, consider finding a mentor with experience in the engine manufacturing industry to guide you through the complexities of launching your business.

Conduct Comprehensive Market Research

Understanding your target market is essential. Utilize tools and platforms that provide insights about automotive engine production trends and the competitive landscape. By conducting thorough market research for manufacturing, you can identify gaps and opportunities that your engine manufacturing company can fulfill.

Develop a Solid Business Model

Creating a manufacturing business plan is crucial. Outline your vision, mission, operations, and financial projections. This plan should also detail your value proposition, including how your engines will address the growing demand for environmentally friendly solutions.

Seek Financial Backing

- Explore crowdfunding platforms or small business grants that support green technologies and manufacturing.

- Network to find investors for engine manufacturing who share a vision for innovation.

Understand Permits and Licenses

Research the necessary manufacturing permits and licenses specific to the automotive or aerospace sectors. Compliance is critical to avoid legal issues and ensure smooth operations from day one.

Assemble a Skilled Team

Identifying the right talent is essential for your company's success. Focus on hiring skilled engineers and technicians who have experience in quality control in manufacturing. A competent team will help you innovate and maintain the high standards expected in the engine manufacturing industry.

Implement Quality Control Measures

Establishing strict quality control measures from the outset will help build a reputable brand. Utilize state-of-the-art technologies to ensure your products meet regulatory standards and customers’ expectations.

Launch and Monitor Operations

Once all the groundwork is laid, you can launch your engine manufacturing business. Monitoring performance and customer feedback will help refine your processes and product offerings over time. It’s a continuous journey of learning and adaptation.

How Do I Start An Engine Manufacturing Company With No Money?

Starting an engine manufacturing business without any capital may seem daunting, but it's not impossible. Many successful entrepreneurs have launched their ventures using creativity and resourcefulness. Here are proven strategies to help you kickstart your engine manufacturing company:

- Leverage Partnerships: Collaborate with established companies in the automotive or aerospace sector. These businesses may provide funding or resources in exchange for a share in the profits or products.

- Seek Out Grants and Competitions: Look for government grants, innovation challenges, or startup competitions that support manufacturing businesses. Winning these can provide both funds and exposure.

- Crowdfunding: Utilize platforms like Kickstarter or Indiegogo to raise funds by showcasing your innovative engine designs or eco-friendly manufacturing processes. This option allows you to validate your business model while gathering capital.

- Build a Prototype: Consider creating a simple prototype of your engine using low-cost materials. This tangible representation can attract interest from investors or partners.

- Negotiate Deferred Payments: When establishing your supply chain for materials, negotiate for deferred payments. This allows you to acquire necessary components without immediate cash outlays.

- Utilize Online Resources: Take advantage of free online courses and tutorials focused on manufacturing technology, business planning, and market research. Websites like Coursera or edX can equip you with skills without financial investment.

It's critical to conduct thorough market research for manufacturing to identify gaps in the market and position your business effectively. The engine manufacturing industry has seen trends shifting toward sustainability, which you can capitalize on by incorporating environmentally friendly solutions in your offerings.

Tips For Attracting Investors

- Prepare a compelling pitch that highlights your unique value proposition and potential market opportunities.

- Network with industry professionals to gain insights and introductions to potential investors for engine manufacturing.

- Demonstrate clear growth potential with a solid manufacturing business plan that outlines your goals, target market, and projected earnings.

When you have no money, your approach to starting an engine manufacturing company should focus on strategic planning and relationship-building. Look for alternative funding sources and leverage your network to mitigate financial challenges. Remember, creativity and persistence can often compensate for initial capital constraints.

Example Of Checklist For Opening An Engine Manufacturing Company

Starting an engine manufacturing business is an intricate venture that requires meticulous planning and execution. Below is a detailed checklist to guide you through the process of launching your own engine manufacturing company effectively.

Conduct Market Research To Identify Opportunities

Understanding the engine manufacturing industry trends is critical. Analyze market needs, customer preferences, and competitor strategies.

Develop A Comprehensive Business Model

Design a robust business model for engine manufacturing that includes your value propositions, target market, revenue streams, and cost structure. This framework is essential for convincing potential investors for engine manufacturing.

Secure Necessary Permits And Licenses

Obtain all required manufacturing permits and licenses pertinent to your locality to ensure compliance with regulations. The costs for permits can vary significantly, ranging from a few hundred to thousands of dollars depending on the jurisdiction.

Establish A Supply Chain For Materials

Build a reliable engine component supply chain. Partner with suppliers for quality materials and components necessary for production. Consider negotiating contracts to ensure pricing stability.

Invest In Advanced Technology And Equipment

Invest in advanced manufacturing technology to enhance efficiency and productivity. This includes CNC machines, robotics, and specialized software, which can lead to cost savings of up to 20% through increased automation.

Hire Skilled Engineers And Technicians

The success of your operation heavily relies on having the right talent. Focus on hiring engineers for manufacturing with experience in automotive or aerospace sectors. Competitive salaries and benefits can attract top talent.

Create A Marketing Strategy To Attract Clients

Develop a marketing strategy that includes both digital and traditional formats. Highlight the unique selling points of your engines, such as efficiency and environmental compliance.

Implement Quality Control Measures

Establish stringent quality control in manufacturing processes to ensure the durability and reliability of your products. Implementing these measures can reduce manufacturing defects by over 30%.

Launch Operations And Monitor Performance

Once all systems are in place, launch your operations. Regularly monitor performance metrics to assess productivity and identify areas for improvement. Utilize key performance indicators to track progress effectively.

Tips for Successful Engine Manufacturing Startup

- Build relationships with automotive and aerospace companies to secure contracts early on.

- Stay updated on governmental regulations and industry changes to adapt swiftly.

Following this engine manufacturing checklist can significantly increase your chances of successfully launching a profitable venture in this competitive field. Starting an engine manufacturing company may seem daunting, but with careful planning and execution, opportunities abound in this innovative industry.

How Long Does It Take To Start An Engine Manufacturing Company?

The timeline for starting an engine manufacturing company can vary significantly based on various factors, including business scope, funding, and regulatory requirements. Generally, it can take anywhere from 6 months to 2 years to fully launch your engine manufacturing business. Here’s a breakdown of what you can expect during this time frame:

- Market Research: 1-3 months. Conduct thorough market research for manufacturing to identify opportunities and challenges within the engine manufacturing industry.

- Business Planning: 1-2 months. Create a detailed manufacturing business plan that outlines your business model for engine manufacturing.

- Permits and Licensing: 2-4 months. Securing the necessary manufacturing permits and licenses is critical and can be time-consuming, depending on your location.

- Funding and Investment: 1-3 months. Finding investors for engine manufacturing can also extend your timeline, as it may take time to negotiate terms and secure capital.

- Setting Up Operations: 3-6 months. This phase involves establishing your supply chain for materials, investing in advanced manufacturing technology, and hiring engineers for manufacturing.

- Quality Control Implementation: 1-2 months. Implementing robust quality control measures is necessary to meet industry standards and expectations.

- Marketing Strategy Development: 1-2 months. Creating a marketing strategy to attract clients in the engine manufacturing sector is essential for launching your business successfully.

Ultimately, the speed of these processes will depend on your resources and commitment. To expedite your startup, consider these tips:

Tips for a Faster Launch

- Engage consultants who have experience in the engine manufacturing industry to navigate regulations and speed up the permitting process.

- Leverage existing relationships with suppliers to streamline your supply chain.

- Consider crowdfunding or angel investors for a quicker funding process.

- Use templates for your manufacturing business plan to save time.

According to industry benchmarks, a well-prepared business can significantly reduce the time required to hit operational milestones. It’s critical to keep a flexible timeline while working towards your goals, as delays in one area can impact subsequent phases of your launch.

How Can I Find Investors For Starting An Engine Manufacturing Company?

Finding investors for your engine manufacturing company can be a challenging yet rewarding process. It’s crucial to present a compelling case for why your venture, Engine Innovations Corp, is an attractive investment opportunity. Here are several strategies to attract potential investors:

- Leverage Your Network: Connect with industry professionals, former colleagues, and acquaintances who may know investors looking for opportunities in the engine manufacturing sector. Networking events or industry conferences can be great platforms for these connections.

- Utilize Online Platforms: Websites like AngelList, Kickstarter, and Indiegogo allow entrepreneurs to showcase their business ideas and attract funding from a diverse pool of investors.

- Prepare a Solid Business Plan: A well-structured manufacturing business plan is essential when seeking investors. Outline your business model for engine manufacturing, market research findings, and financial projections clearly to build credibility.

- Pitch Competitions: Participate in startup pitch competitions. These events not only provide exposure but also valuable feedback from a panel of seasoned investors. Winning a pitch can significantly boost your visibility.

- Seek Out Angel Investors and Venture Capitalists: Research companies or individuals that focus on funding manufacturing startups. Tailor your pitch to their interests, focusing on the innovative aspects of your engine manufacturing plans.

Tips for Finding Investors

- Highlight Market Trends: Investors are attracted to sectors that show potential for growth. Share insights about current engine manufacturing industry trends, especially regarding sustainable and advanced manufacturing technologies.

- Showcase Financial Viability: Provide clear metrics on how investments will lead to profitability. According to various industry benchmarks, companies in the engine manufacturing field can expect a gross margin ranging from 25% to 40%.

- Demonstrate a Strong Team: Investors want assurance that the team behind the project has the necessary expertise. Highlight your plans for hiring engineers for manufacturing and your commitment to building a skilled workforce.

Remember, transparency and clear communication are vital in building trust with potential investors. A strong pitch that combines your innovative approach to engine manufacturing with solid market research and financial planning can significantly enhance your chances of securing funding.

How Do I Create A Successful Business Plan For An Engine Manufacturing Company?

Creating a successful business plan for your engine manufacturing company, such as Engine Innovations Corp, involves several critical components. This plan should effectively outline your vision, operational strategies, and financial projections to attract potential investors and guide your startup journey.

- Executive Summary: Start with a compelling executive summary that encapsulates your business idea, goals, and the unique value proposition of your engine manufacturing business. Highlight what makes your offerings stand out, especially regarding innovation and environmental sustainability.

- Market Analysis: Conduct thorough market research for manufacturing to identify industry trends, potential competitors, and customer needs. A well-researched market analysis can highlight the demand for environmentally friendly engine solutions and demonstrate your understanding of the automotive and aerospace sectors.

- Business Model: Develop a solid business model for engine manufacturing that includes revenue streams, pricing strategies, and logistics. Consider models like direct sales, contract manufacturing, or subscription services for maintenance and support.

- Operations Plan: Outline your operational strategy, including how you will establish the engine component supply chain. Address the advanced manufacturing technology required, such as robotics and AI-driven systems, which are becoming increasingly important in the engine manufacturing industry.

- Financial Projections: Provide realistic financial forecasts, including startup costs, projected revenue, and profit margins. According to industry benchmarks, starting an engine manufacturing business can require capital ranging from $500,000 to $2 million, depending on your scale and technology investments.

- Marketing Strategy: Develop a marketing strategy that effectively communicates your brand values and offerings. Include tactics for attracting clients through digital marketing, trade shows, and partnerships within the aerospace and automotive sectors.

- Quality Control Measures: Emphasize the importance of quality control in manufacturing by detailing the quality assurance processes you will put in place to ensure compliance with industry standards and regulations.

Tips for Homework

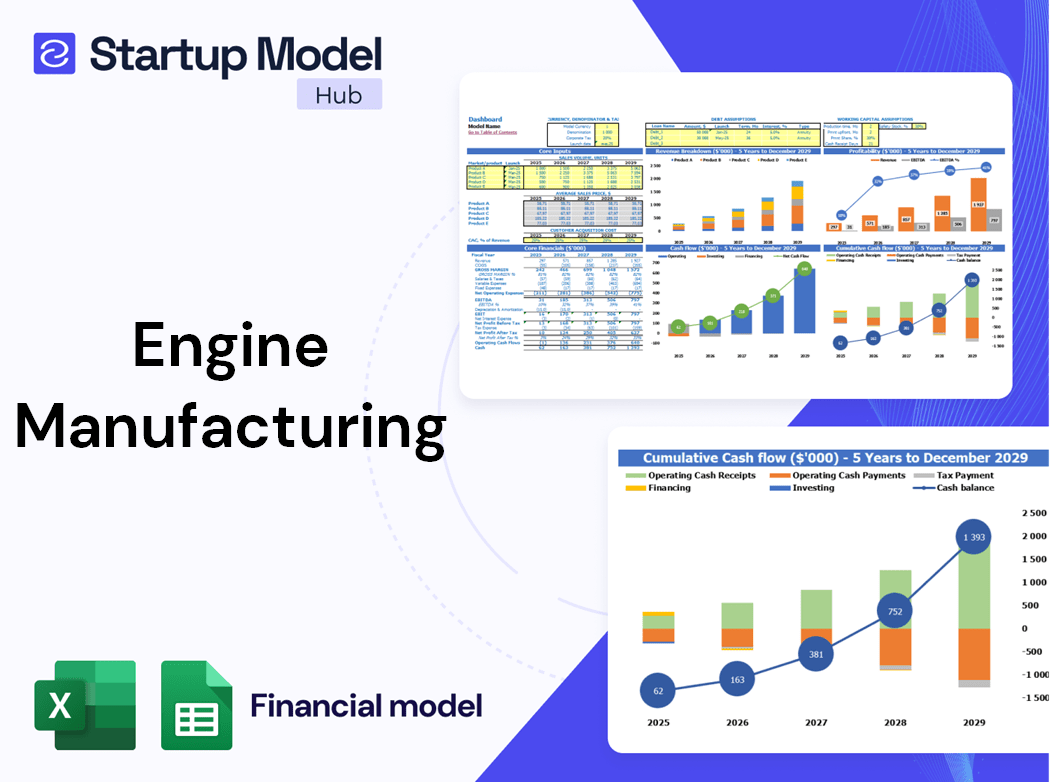

- Utilize templates and resources from reputable sources, such as financial model templates, to structure your financial projections effectively.

Moreover, consider including a section that outlines potential challenges in engine manufacturing startups, along with strategies to mitigate these risks. Being prepared for issues like supply chain disruptions and market fluctuations can provide confidence to investors looking for viable opportunities.

Checklist For Opening An Engine Manufacturing Company

Starting your own engine manufacturing business requires careful planning and thorough execution. Below is a comprehensive engine manufacturing checklist designed to guide you through each critical step of launching your company:

Conduct Market Research To Identify Opportunities

Understanding your target market is essential. Analyze current engine manufacturing industry trends to identify gaps or opportunities for innovation. This research will help you tailor your products to meet industry demands.

Develop A Comprehensive Business Model

Your business model should outline how your engine manufacturing company will operate, including details on automotive engine production, pricing strategies, and revenue streams. Consider different models such as custom engine solutions or a product line for standard engines.

Secure Necessary Permits And Licenses

Before embarking on manufacturing, ensure you have the necessary manufacturing permits and licenses. This varies by location but generally includes safety, environmental, and zoning permits.

Establish A Supply Chain For Materials

A robust engine component supply chain is crucial for timely production. Identify reliable suppliers for materials and parts, ensuring compliance with industry standards and regulations.

Invest In Advanced Technology And Equipment

To maintain a competitive edge, invest in advanced manufacturing technology. This may include robotics for assembly lines or cutting-edge software for design and testing.

Hire Skilled Engineers And Technicians

Your team is your greatest asset. Focus on hiring engineers for manufacturing who have specialized skills and experience in engine design and production.

Create A Marketing Strategy To Attract Clients

Implement a targeted marketing strategy to attract clients. Highlight your unique selling points, like eco-friendly solutions or superior performance, and utilize both digital and traditional marketing channels.

Implement Quality Control Measures

Quality should never be compromised in engine manufacturing. Integrate quality control in manufacturing processes at every stage to ensure the highest standards are maintained, reducing defects and enhancing customer satisfaction.

Launch Operations And Monitor Performance

After setting everything in place, launch your operations. Regularly monitor performance metrics to ensure you're meeting your manufacturing business plan objectives and adjust strategies as necessary to improve efficiency.

Tip for Success:

- Consider using financial models and KPIs to track your profitability and operational efficiency. These tools are essential for making informed business decisions and securing investors for engine manufacturing.

By following this checklist, you will be well-equipped to start an engine manufacturing company effectively and position yourself for long-term success in the competitive engine manufacturing landscape. For additional insights, refer to resources on cost and financial planning in engine manufacturing.

Conduct Market Research To Identify Opportunities

Market research is a fundamental step for anyone looking to start an engine manufacturing company. Understanding the dynamics of the engine manufacturing industry, including current trends and customer needs, is crucial for positioning your business effectively. In 2022, the global engine manufacturing market was valued at approximately $247 billion and is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2028. This growth presents numerous opportunities for new entrants who can innovate and meet the evolving demands of the market.

Here is a structured approach to conducting market research for your engine manufacturing business:

- Identify Your Target Market: Determine which sectors—automotive, aerospace, or industrial—would benefit most from your engine solutions.

- Analyze Industry Trends: Keep abreast of trends such as the shift towards electric and hybrid engines, which are increasingly popular due to environmental concerns.

- Assess Competition: Study existing players in the market to understand their strengths and weaknesses. This will help you carve out your niche.

- Gather Customer Feedback: Engage with potential customers through surveys or interviews to discover their pain points and requirements.

Tips for Effective Market Research

- Utilize online databases and industry reports for comprehensive insights.

- Participate in industry trade shows to network and gather firsthand information.

- Consider conducting a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) to better understand your position in the marketplace.

In addition to understanding the market, you should also focus on your business model for engine manufacturing. A well-defined business model can help you identify specific opportunities for differentiation and innovation. For instance, leveraging advanced manufacturing technology can drastically improve production efficiency and reduce costs.

To quantify your market research, consider the following benchmarks:

| Category | Market Size (2022) | Projected CAGR (2028) |

|---|---|---|

| Automotive Engine Production | $180 billion | 4.6% |

| Aerospace Engine Production | $67 billion | 4.2% |

| Industrial Engine Production | $27 billion | 3.9% |

By methodically conducting market research, you can significantly reduce the risks associated with opening an engine manufacturing business. This foundational step will guide your strategic decisions and help you attract investors for engine manufacturing while ensuring compliance with manufacturing permits and licenses.

For further assistance in developing your manufacturing business plan, consider using comprehensive financial models tailored for the engine manufacturing sector. Tools like this financial model can help you project your financial outcomes and make data-driven decisions.

Develop A Comprehensive Business Model

Creating a robust business model is a critical step when you decide to start an engine manufacturing company. Your business model will outline how your company will create value, deliver products, and capture revenue within the highly competitive engine manufacturing industry. It should address key components such as target market, value proposition, revenue streams, cost structure, and competitive advantage.

Key Components of a Business Model for Engine Manufacturing

- Target Market: Identify the specific sectors you will serve—automotive, aerospace, or both. Understand the needs of your clients, whether they require high-performance engines or environmentally friendly solutions.

- Value Proposition: Define what makes your offerings unique. Will you focus on innovation, sustainability, or cost-effectiveness? Clearly articulate these benefits to customers.

- Revenue Streams: Determine how your engine manufacturing business will earn money. Consider multiple streams such as direct sales, contracts, and aftermarket services.

- Cost Structure: Analyze the costs associated with manufacturing processes, labor, materials, and technology investments to ensure profitability.

- Competitive Advantage: Establish the factors that give your company an edge over others—this might include advanced manufacturing technology or specialized engine designs.

Business Model Canvas

Utilizing a Business Model Canvas can streamline this process. This visual tool helps organize your thoughts and ensure all aspects of your business model are covered. Here’s a simple template that might guide you:

| Key Partners | Key Activities | Key Resources |

| Suppliers | Engine design and production | Manufacturing facilities |

| Distributors | Quality control measures | Advanced technology |

| Regulatory bodies | Marketing and sales | Skilled workforce |

| Value Proposition | Customer Relationships | Channels |

| Innovative engine solutions | Customer support | Direct sales |

| Environmentally friendly options | Long-term partnerships | Industry events |

| Customer Segments | Cost Structure | Revenue Streams |

| Automotive manufacturers | Fixed costs (rent, salaries) | Product sales |

| Aerospace companies | Variable costs (materials) | Service contracts |

Tips for Developing Your Business Model

- Conduct thorough market research for manufacturing to validate your assumptions about customer needs and market trends. This will help refine your value proposition.

- Consider creating a manufacturing business plan that clearly outlines your business model, as this will also be crucial for attracting investors for engine manufacturing.

- Stay updated on engine manufacturing industry trends to adjust your business model accordingly and maintain a competitive edge.

By carefully constructing a comprehensive business model, you will significantly increase your chances of successfully launching your engine manufacturing business. It not only serves as a roadmap for you but is also vital information to share with potential investors, showcasing the viability and sustainability of your venture.

Secure Necessary Permits And Licenses

Embarking on the journey to start an engine manufacturing company requires a thorough understanding of the regulatory landscape. Securing the appropriate manufacturing permits and licenses is paramount to ensure compliance with local, state, and federal regulations. This process not only validates your business's legitimacy but also protects your venture against potential legalities that can arise from non-compliance.

Here are the critical steps to consider when navigating the permit and licensing process:

- Research local, state, and federal regulations specific to engine manufacturing.

- Determine the specific manufacturing permits and licenses required for your operations.

- Understand the environmental regulations pertaining to emissions and waste disposal.

- Consult legal experts or industry consultants to ensure compliance.

- Prepare and submit the necessary documentation for permits and licenses.

- Keep track of renewal dates for ongoing compliance with regulatory requirements.

For Engine Innovations Corp, focusing on innovative and environmentally friendly engine solutions means you may also need additional certifications related to sustainability and efficiency. This could include:

- ISO 9001 for quality management systems.

- ISO 14001 for environmental management systems.

- SAE International standards applicable to automotive engine production.

Tips for Securing Permits and Licenses:

- Engage with local business development agencies to get guidance tailored to your region.

- Regularly review changes in legislation that may affect your licensing requirements.

- Document all communications and submissions to facilitate future audits or inquiries.

The timeline for obtaining the necessary permits can vary significantly based on location and the complexity of your manufacturing operations. On average, it can take anywhere from 3 to 12 months to secure all required licenses and permits.

| Type of Permit/License | Estimated Cost | Average Processing Time |

|---|---|---|

| Business License | $50 - $500 | 2 weeks - 3 months |

| Environmental Permits | $1000 - $5000 | 1 month - 6 months |

| Building Permits | $500 - $2000 | 2 weeks - 4 months |

Working with seasoned professionals in the field, including legal advisors with expertise in the engine manufacturing industry, can significantly streamline this process. By ensuring that your manufacturing business plan includes a robust section on compliance and regulatory considerations, you position your venture to operate smoothly right from launch.

For more detailed financial guidance tailored to the engine manufacturing sector, consider visiting this business plan resource.

In conclusion, being proactive about obtaining the right permits and licenses is a foundational step in establishing a successful engine manufacturing business. With the appropriate measures in place, your company can focus on innovation and excellence in the competitive engine manufacturing landscape.

Establish A Supply Chain For Materials

One of the foundational pillars of starting an engine manufacturing business is establishing a robust supply chain for materials. The engine manufacturing industry demands precision and quality, which makes sourcing the right materials critical for production efficiency and product quality.

To successfully open an engine manufacturing company, it's essential to create relationships with reliable suppliers who can deliver the necessary components, such as alloys for engine blocks and specialized materials for high-performance engine parts. The following steps can guide you in building an effective supply chain:

- Identify key materials needed for engine production, such as aluminum, steel, and composite materials that comply with industry regulations.

- Research potential supplier options, focusing on those who specialize in the engine component supply chain.

- Evaluate suppliers based on quality, cost, delivery times, and their ability to scale with your business.

- Establish contracts with selected suppliers to ensure consistent material availability.

- Implement a monitoring system to evaluate supplier performance regularly, which is vital for maintaining quality control in manufacturing.

Tips for Establishing a Supply Chain

- Consider diversifying suppliers to mitigate risks associated with supply chain disruptions.

- Negotiate long-term contracts for better pricing and reliable supply.

- Invest in advanced manufacturing technology to track inventory and streamline procurement processes.

Adopting an effective supply chain strategy can directly impact your profit margins. For instance, reducing material costs by just 5% can significantly enhance your overall profitability. Research shows that companies with optimized supply chains can achieve a 15% reduction in production costs compared to those without a robust system in place.

| Material Type | Supplier Options | Average Cost per Unit |

|---|---|---|

| Aluminum Alloy | Supplier A, Supplier B | $1.50 |

| High-Strength Steel | Supplier C, Supplier D | $0.80 |

| Composite Material | Supplier E, Supplier F | $4.00 |

Ensuring that your engine manufacturing business has access to high-quality materials is crucial for producing reliable and high-performance engines. Additionally, consider utilizing resources such as a comprehensive manufacturing business plan specifically designed for the engine sector. This can help streamline your operations and improve overall efficiency.

Invest In Advanced Technology And Equipment

In the competitive landscape of the engine manufacturing business, investing in advanced technology and equipment is not just an option; it's a necessity. The shift towards more efficient and environmentally friendly solutions has transformed how engines are designed and produced. By leveraging cutting-edge technologies, you can significantly enhance your production capabilities, reduce operational costs, and improve product quality. This investment is vital for launching an engine manufacturing business that meets the modern demands of the automotive and aerospace sectors.

To stay ahead in the market, you must focus on acquiring the following advanced technologies and equipment:

- Computer-Aided Design (CAD) Software: Essential for designing engine components with precision.

- 3D Printing Technology: Enables rapid prototyping and production of complex engine parts, thus reducing lead times.

- Robotics and Automation: Enhances efficiency and consistency in manufacturing processes, leading to lower production costs.

- Quality Control Systems: Advanced systems that monitor production in real-time to ensure adherence to quality standards.

- Material Testing Equipment: Crucial for assessing the durability and performance of materials used in engine production.

Investing in these technologies not only elevates your operational efficiency but also positions your company as a leader in innovation within the engine manufacturing industry.

| Technology | Benefits | Estimated Cost |

|---|---|---|

| CAD Software | Precision design, reduced errors | $5,000 - $20,000 |

| 3D Printing | Faster prototyping, complex designs | $10,000 - $100,000 |

| Robotics | Increased efficiency, cost reduction | $50,000 - $500,000 |

Tips for Investing in Technology

- Assess your production needs thoroughly before making equipment purchases.

- Opt for scalable technology solutions that can grow with your engine manufacturing company.

- Consider second-hand or refurbished equipment to lower initial costs without sacrificing quality.

The long-term savings associated with advanced manufacturing technologies can be substantial. For instance, automotive engine production has seen efficiency improvements of up to 30% through the adoption of automation and robotics. Moreover, investing in the right equipment can contribute to a faster return on investment (ROI), enabling your business to thrive as it meets the evolving standards of the market.

To craft a comprehensive manufacturing business plan, prioritize detailed assessments of capital expenditures for technology, potential returns, and timelines for implementation. Integrating these elements into your strategy will not only attract potential investors for engine manufacturing but also establish a robust foundation for future growth.

Remember, the choice of technology and equipment directly impacts your ability to meet manufacturing permits and licenses requirements, as top-tier technologies often comply with stricter industry standards. Therefore, it is essential to stay updated on the engine manufacturing industry trends to ensure your company remains compliant and competitive.

Hire Skilled Engineers And Technicians

When you decide to start an engine manufacturing company, one of the most crucial steps is to hire a team of skilled engineers and technicians. The success of your engine manufacturing business largely hinges on the expertise and capabilities of your workforce. In an industry characterized by rapid technological advancements and stringent regulatory requirements, having a knowledgeable and skilled team can make all the difference.

The engine manufacturing industry is evolving rapidly, with a marked shift towards sustainability and high efficiency. According to the latest industry statistics, skilled engineers are among the most sought-after professionals, with a projected job growth rate of 4% to 6% over the next decade across engineering disciplines. This trend underscores the need to attract qualified personnel who can contribute positively to the growth of your venture.

Here are essential roles to consider when hiring for your engine manufacturing company:

- Mechanical Engineers: Essential for designing and optimizing engine components.

- Manufacturing Engineers: Critical for streamlining production processes.

- Quality Control Specialists: Ensure adherence to quality standards and regulations.

- Maintenance Technicians: Maintain machinery and equipment for smooth operations.

- Research and Development Engineers: Innovate and develop new engine technologies.

Understanding the challenges in engine manufacturing startups is vital. High initial investment, adherence to manufacturing permits and licenses, and ensuring quality control can often be overwhelming. By assembling a capable team, you lay a solid foundation that can handle these challenges effectively.

| Role | Average Salary (USD) | Importance |

|---|---|---|

| Mechanical Engineer | $85,000 | Crucial for design and optimization |

| Manufacturing Engineer | $80,000 | Streamlines production processes |

| Quality Control Specialist | $67,000 | Ensures product quality and compliance |

| Maintenance Technician | $55,000 | Maintains operational machinery |

| R&D Engineer | $90,000 | Innovates new engine technologies |

Tips for Hiring Skilled Engineers

- Network through industry-specific job fairs to find qualified candidates.

- Utilize online platforms like LinkedIn and specialized engineering job boards.

- Consider offering competitive salaries and benefits to attract top talent.

- Implement internship programs to build a pipeline of skilled future employees.

As you craft your manufacturing business plan, make sure to allocate resources for hiring and retaining skilled engineers. The cost of hiring the right talent, while significant, often yields a high return on investment through increased productivity and innovation. Your choice in personnel can directly influence your company's ability to attract investors for engine manufacturing, meet project deadlines, and maintain high standards of quality control in manufacturing.

Investing in advanced manufacturing technology and creating a supportive work environment also plays a crucial role in retaining talent. By fostering a culture of continuous learning and innovation, you will not only improve employee satisfaction but also enhance your company's competitive edge in the market.

To streamline your journey further, consider leveraging financial models tailored to the engine manufacturing sector. Check out this comprehensive resource to guide your planning: Engine Manufacturing Financial Model.

Create A Marketing Strategy To Attract Clients

Creating an effective marketing strategy is essential for any engine manufacturing business looking to gain a foothold in a competitive marketplace. A well-structured approach ensures that your company, such as Engine Innovations Corp, not only reaches potential clients but also resonates with their specific needs. Here are key components to consider when crafting your marketing strategy:

- Target Market Identification: Conduct thorough market research for manufacturing to identify and segment your potential customer base. Focus on sectors like automotive and aerospace, which are increasingly demanding eco-friendly and high-performance solutions.

- Brand Positioning: Define a unique selling proposition (USP) that differentiates your offerings from competitors. Highlight your commitment to innovative and environmentally friendly solutions, making it clear why clients should choose your engine manufacturing company.

- Digital Marketing: Leverage digital channels such as SEO, social media, and pay-per-click advertising to reach broader audiences. This is crucial for generating leads and establishing your brand presence online.

- Content Marketing: Create engaging content that addresses the challenges faced by your target market. This can include whitepapers, blogs, and case studies that showcase your advanced manufacturing technology and innovative solutions.

- Networking and Partnerships: Attend industry conferences and workshops to build relationships with potential clients and other stakeholders. Establishing a robust engine component supply chain through partnerships can also enhance your credibility.

- Customer Testimonials and Case Studies: Use success stories and positive feedback from early clients to build trust with prospective customers. This social proof can help to alleviate concerns and showcase the effectiveness of your engines.

- Sales Strategies: Develop a sales strategy that aligns with your marketing efforts, ensuring your sales team is equipped with the right materials and information to effectively communicate your brand's value.

To further enhance your marketing strategy, consider the following tips:

Tips for a Successful Marketing Strategy

- Utilize analytics tools to track your marketing efforts and adjust strategies accordingly based on performance data.

- Engage in continuous learning about engine manufacturing industry trends to stay ahead of the competition.

- Be responsive to feedback from clients to refine your offerings and improve customer satisfaction.

Statistics indicate that a strong marketing strategy can increase a business's revenue by up to 30%. By implementing a structured approach tailored to the unique needs of your engine manufacturing company, you can achieve significant growth and client retention.

| Strategy Component | Importance | Expected Outcome |

|---|---|---|

| Target Market Identification | High | Clear understanding of customer needs |

| Digital Marketing | Critical | Increased online presence and lead generation |

| Customer Testimonials | Essential | Enhanced credibility and trust |

It's also crucial to monitor your marketing efforts continuously and adapt to the challenges in engine manufacturing startups. Being proactive in your marketing will set the groundwork for your long-term success in the industry.

For anyone looking to kickstart their journey in this field, consider utilizing resources such as a comprehensive manufacturing business plan that outlines the financial modeling and strategies essential for a successful launch.

Implement Quality Control Measures

In the engine manufacturing business, quality control is paramount. A well-defined quality control process ensures that every engine produced meets rigorous standards and regulations, ultimately leading to customer satisfaction and repeat business. Implementing effective quality control measures not only minimizes defects but also enhances productivity and reduces costs associated with rework and returns.

To establish an effective quality control system, consider the following key components:

- Define Quality Standards: Develop clear specifications for each product, including material requirements, performance metrics, and environmental compliance. This will serve as the baseline for quality assessment.

- Invest in Advanced Manufacturing Technology: Utilizing technology such as AI, IoT, and automation can enhance precision in production processes, allowing for real-time quality assessment and reducing human error.

- Conduct Regular Inspections: Implement a structured inspection process at various stages of production, ensuring that every component is thoroughly evaluated before assembly.

- Calibration and Maintenance: Regularly calibrate machinery and tools to ensure optimal performance and accuracy, which directly impacts the quality of the final product.

- Training and Certification: Continuously train your workforce on quality standards and the latest manufacturing techniques. Certified personnel are crucial for maintaining high-quality outputs.

- Implement Feedback Loops: Create channels for feedback from clients and employees to identify areas for improvement in both products and processes.

Monitoring Quality Control Metrics

- Track defect rates throughout the manufacturing process to identify trends.

- Measure customer satisfaction scores to gauge the effectiveness of quality control measures.

- Analyze compliance with industry regulations to avoid costly fines and reputation damage.

According to industry benchmarks, companies with stringent quality control measures can reduce production defects by 30-50%, leading to significant cost savings and enhanced reputation. In addition, effective quality control can improve customer retention rates by up to 20%, which is crucial in a competitive market like engine manufacturing.

| Quality Control Measure | Expected Impact | Statistical Example |

|---|---|---|

| Regular Inspections | Reduces defects | 30% decrease in defective units |

| Training Programs | Improves employee performance | 20% increase in productivity |

| Feedback Systems | Enhances customer satisfaction | 15% increase in NPS scores |

By prioritizing quality control in your engine manufacturing checklist, you not only enhance product reliability but also foster long-term relationships with your clients. The initial investment in quality control tools and processes is outweighed by the long-term benefits of customer loyalty and reduced operational costs.

For those looking to develop a robust manufacturing business plan, incorporating quality control measures should be a central focus. To further assist you on this journey, explore the comprehensive financial model designed for engine manufacturing businesses available at Engine Manufacturing Financial Model.

Launch Operations And Monitor Performance

Launching operations for your engine manufacturing business is a critical phase that requires careful planning and execution. This stage is not merely about commencing production; it encompasses establishing a robust framework for monitoring and improving performance. To ensure that your engine manufacturing company meets its objectives, you need to implement the following strategies:

- Set Clear Performance Metrics: Define key performance indicators (KPIs) that resonate with your business goals. Common KPIs in the engine manufacturing industry include production efficiency rates, defect rates, and on-time delivery percentages.

- Invest in Advanced Manufacturing Technology: Utilize technologies such as automated assembly lines and real-time data analytics to streamline operations and enhance productivity. Reports have shown that companies that adopt advanced manufacturing technologies can increase productivity by up to 30%.

- Implement Quality Control Measures: Establish a rigorous quality control process to ensure that every engine produced adheres to industry standards. According to statistics, businesses with comprehensive quality control programs experience a 50% reduction in defects.

- Gather Feedback from Clients: Regularly engage with clients to solicit feedback on your products. Understanding customer satisfaction can guide adjustments in production or product design.

- Monitor Financial Performance: Evaluate financial health through regular audits and assessments. Utilizing a reliable manufacturing business plan can help track expenses and revenues effectively.

As you launch your operations, keep in mind the importance of a structured approach to monitoring performance. Here’s a simplified benchmark table illustrating key operational aspects:

| Measurement | Industry Average | Your Target |

|---|---|---|

| Production Efficiency | 75% | 85% |

| Defect Rate | 5% | 2% |

| On-time Delivery | 90% | 95% |

In addition to these measures, consider the following tips for continuous improvement:

Continuous Improvement Strategies

- Conduct regular training for your workforce to improve efficiency and adaptability.

- Use predictive maintenance techniques to foresee equipment failures before they occur.

- Regularly review and adjust your supply chain for optimal material procurement and inventory management.

Furthermore, establishing a feedback loop within your operations can significantly enhance overall performance. By actively monitoring these aspects, you foster a culture of quality and efficiency that will set your engine manufacturing business apart from competitors. Remember, successful operational launch is not a destination, but an ongoing journey of refinement and excellence.

With the right strategies in place, including an effective engine manufacturing checklist, your new venture will be well-equipped to achieve notable growth and sustainability in the competitive landscape of the engine manufacturing sector.